Work protection system for DFB (distributed feed back) laser

A DFB laser and protection system technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve problems such as potential safety hazards, DFB laser drive current and temperature loss of control, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

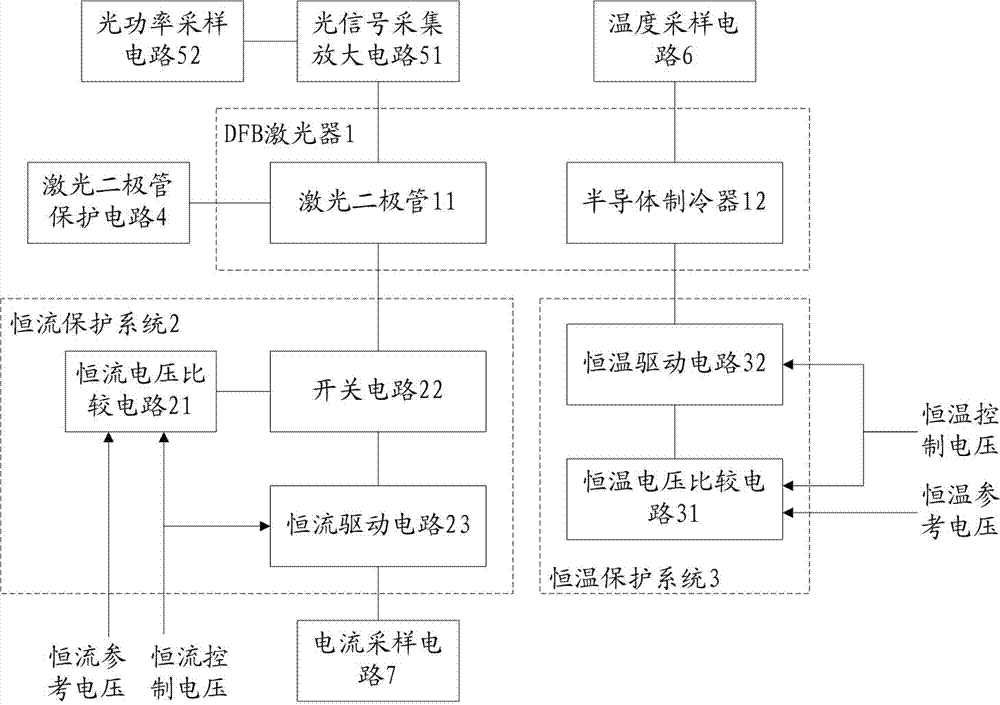

[0036] Such as figure 1 As shown, a working protection system for DFB laser, DFB laser 1 is provided with a laser diode 11 and a semiconductor refrigerator 12, the working protection system includes constant current protection system 2, constant temperature protection system 3, optical signal acquisition and amplification circuit 51. Optical power sampling circuit 52, temperature sampling circuit 6, and current sampling circuit 7.

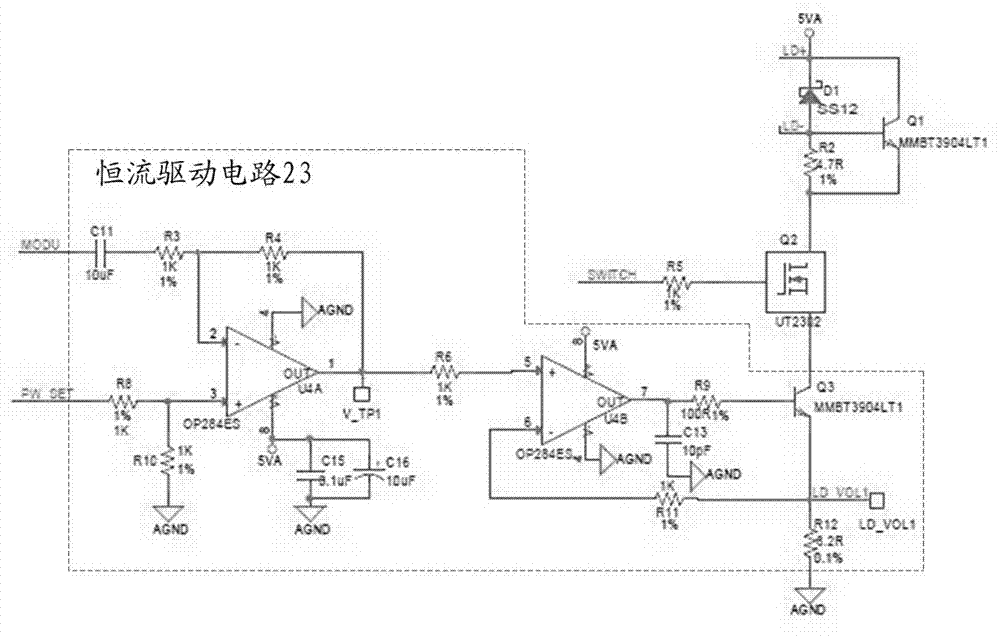

[0037] The constant current protection system 2 includes a constant current voltage comparison circuit 21 , a switch circuit 22 and a constant current drive circuit 23 , and the constant current drive circuit 23 is connected to the laser diode 11 through the switch circuit 22 . Wherein, the constant current voltage comparator circuit 21 comprises a first input terminal, a second input terminal and an output terminal, the switch circuit 22 comprises an input terminal, an output terminal and a control terminal, and the constant current driving circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com