A kind of remediation method of heavy metal polluted soil

A technology of polluted soil and remediation method, which is applied in the restoration of polluted soil, etc., can solve the problems of soil secondary pollution, difficulty in popularization and application of leaching method, and incomplete removal, etc., to achieve easy biodegradation, good leaching effect, The effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

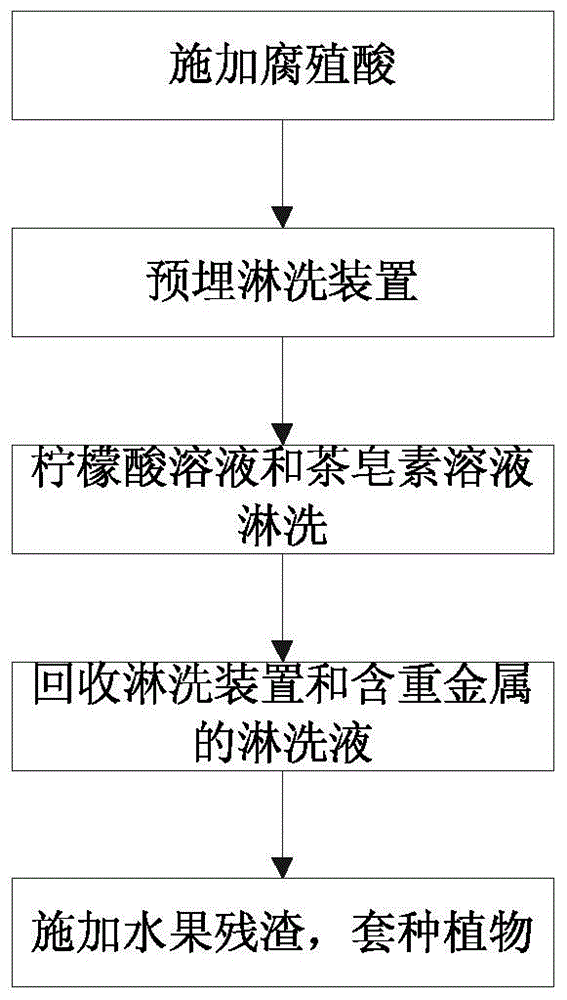

[0024] The remediation method of heavy metal polluted soil provided by the invention comprises the following steps:

[0025] Step 1. Apply humic acid with a thickness of 1 to 5 cm on the surface of the heavy metal-contaminated soil, mix the soil 25 cm thick below the surface of the polluted soil with the humic acid evenly by plowing, and react for 10 days;

[0026] Step 2. After the treatment in step 1, pre-embed a plurality of rinsing devices under the area where the soil is polluted by heavy metals. The rinsing devices include a plurality of drain pipes arranged in parallel with each other. Both ends are sealed and a number of holes are opened on the upper side wall. The two ends of the discharge pipe are respectively erected on two support rods, and a rotating mechanism is arranged between each two discharge pipes. The structure includes a cutter shaft and a rotary knife arranged on the cutter shaft, and the two ends of the cutter shaft are respectively erected on the two s...

Embodiment 2

[0036] A method for repairing heavy metal contaminated soil, comprising the steps of:

[0037] Step 1. Apply humic acid with a thickness of 1 to 5 cm on the surface of the heavy metal-contaminated soil, and mix the soil with a thickness of 20 to 30 cm below the surface of the polluted soil and the humic acid evenly by plowing, and react for 7 to 15 days;

[0038] Step 2. After the treatment in step 1, pre-embed a plurality of rinsing devices under the area where the soil is polluted by heavy metals. The rinsing devices include a plurality of drain pipes arranged in parallel with each other. Both ends are sealed and a number of holes are opened on the upper side wall. The two ends of the discharge pipe are respectively erected on two support rods, and a rotating mechanism is arranged between each two discharge pipes. The structure includes a cutter shaft and a rotary knife arranged on the cutter shaft, and the two ends of the cutter shaft are respectively erected on the two sup...

Embodiment 3

[0048] A method for repairing heavy metal contaminated soil, comprising the steps of:

[0049] Step 1. Apply humic acid with a thickness of 3 cm on the surface of the heavy metal-contaminated soil, mix the soil with a thickness of 25 cm below the polluted soil surface with the humic acid by plowing, and react for 7 days;

[0050] Step 2. After the treatment in step 1, pre-embed a plurality of rinsing devices under the area where the soil is polluted by heavy metals. The rinsing devices include a plurality of drain pipes arranged in parallel with each other. Both ends are sealed and a number of holes are opened on the upper side wall. The two ends of the discharge pipe are respectively erected on two support rods, and a rotating mechanism is arranged between each two discharge pipes. The structure includes a cutter shaft and a rotary knife arranged on the cutter shaft, and the two ends of the cutter shaft are respectively erected on the two support rods;

[0051] Step 3: Pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com