Equipment for deep-hole drilling through vibrating

A deep hole and equipment technology, applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve the problems of low processing efficiency, poor quality of processed holes, unreliable chip breaking and removal, etc., to achieve Improve machining accuracy, reduce chip clogging, improve harsh working conditions and lubricating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

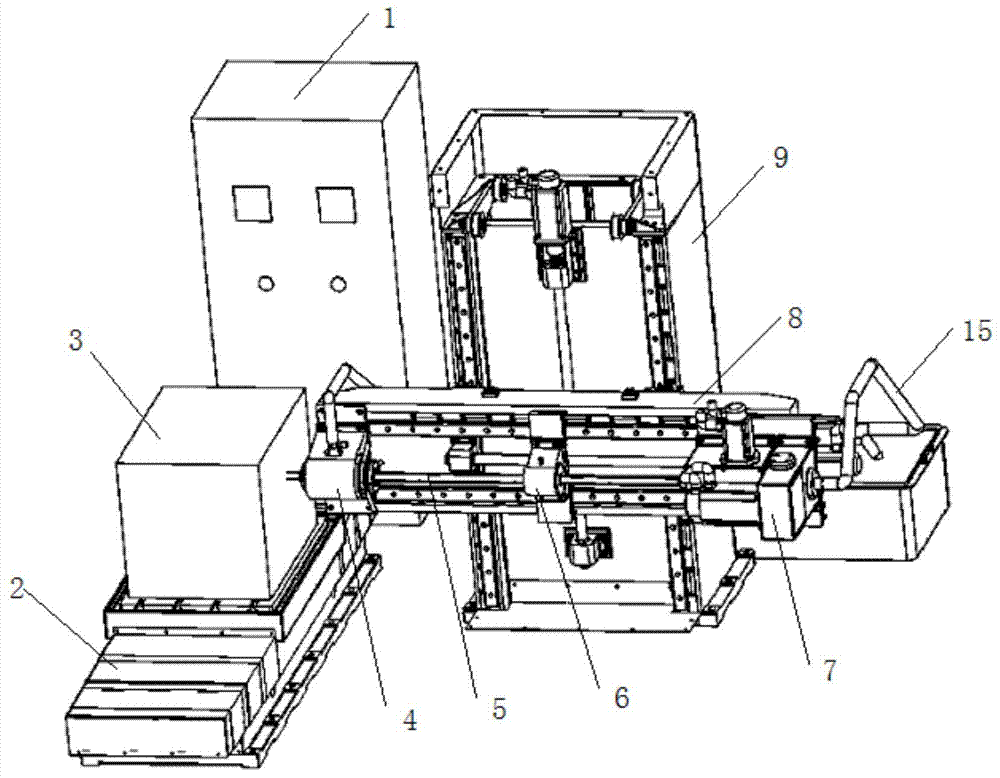

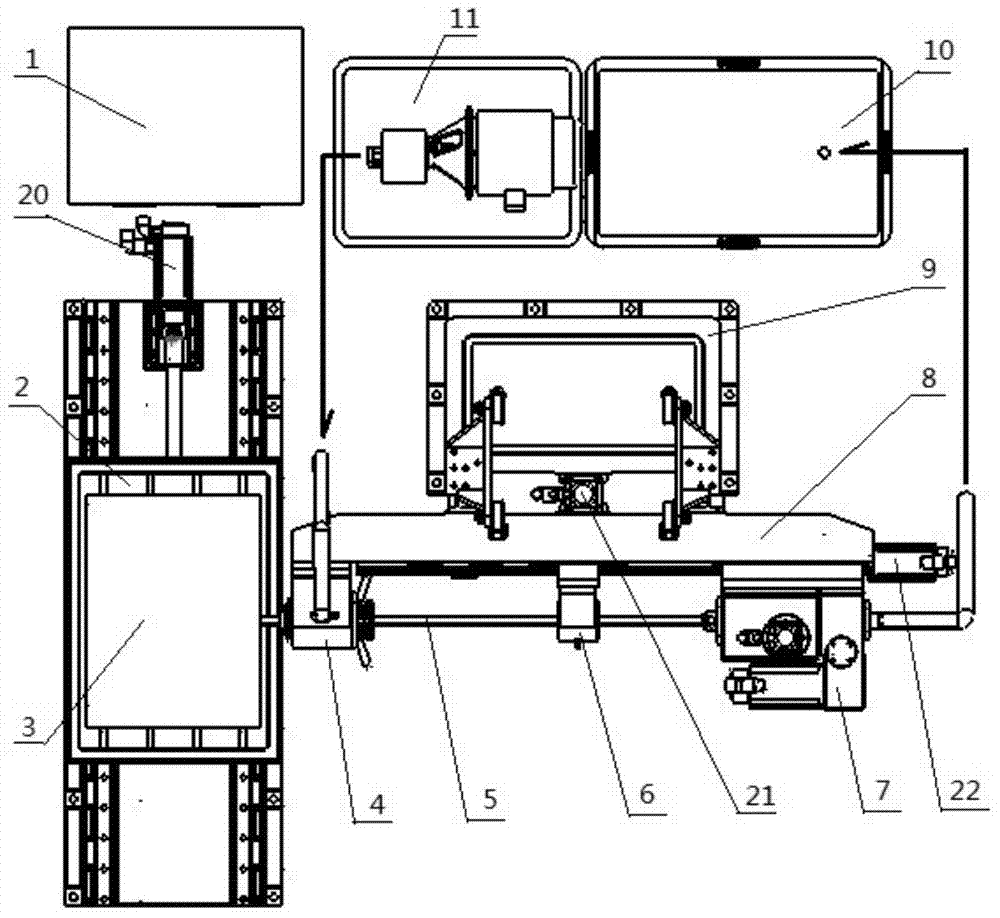

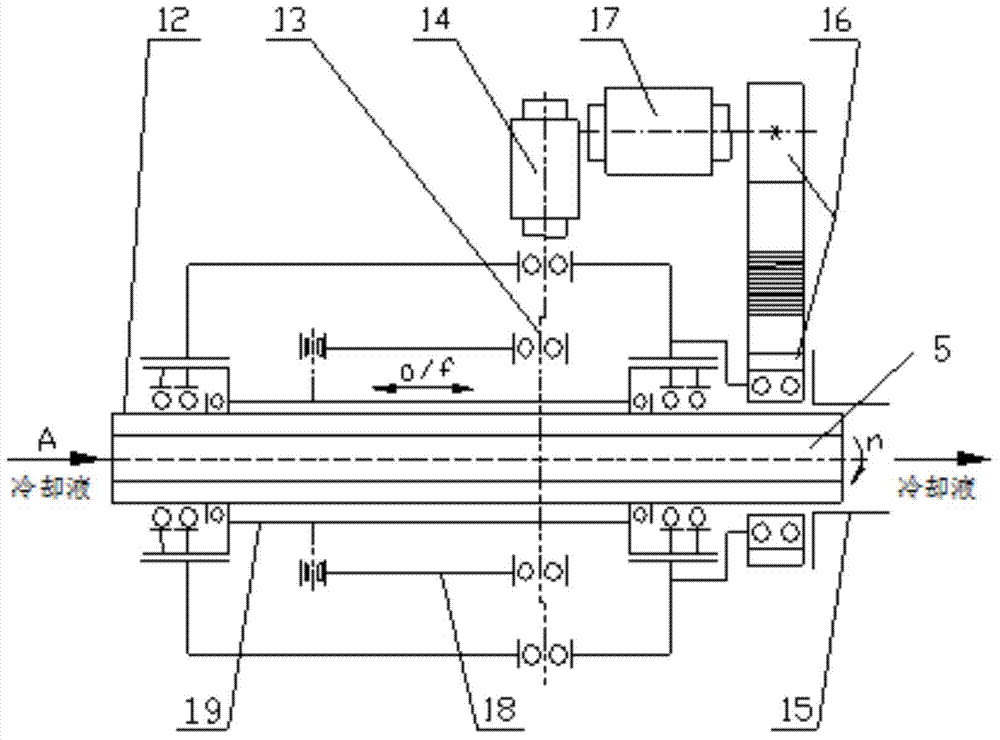

[0024] A device for vibration drilling deep holes, its structure see figure 1 and figure 2 , comprising a column 9, the column 9 is horizontally provided with a crossbeam 8 through the guide rail, one end of the crossbeam 8 is fixedly provided with an oiler 4, the other end of the crossbeam 8 is provided with a vibrating headstock 7, and one end of the vibrating headstock 7 is horizontally provided with a hollow Cutter rod 5, and cutter rod 5 passes through oiler 4, and the other end of vibrating headstock 7 is provided with chip discharge pipe 15.

[0025] The tool bar 5 is fixed on the beam 8 through the vibrating spindle box 7, and the tool bar bracket 6 is arranged on the beam 8. The tool bar support 6 plays an auxiliary supporting role to the tool bar 5 .

[0026] One end of the chip removal pipe 15 away from the vibrating headstock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com