Laser splitting galvanometer scanning and processing device

A galvanometer scanning and processing device technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency and slow processing speed, and achieve improved processing efficiency, high processing speed and processing accuracy, The effect of improving the efficiency and quality of laser processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

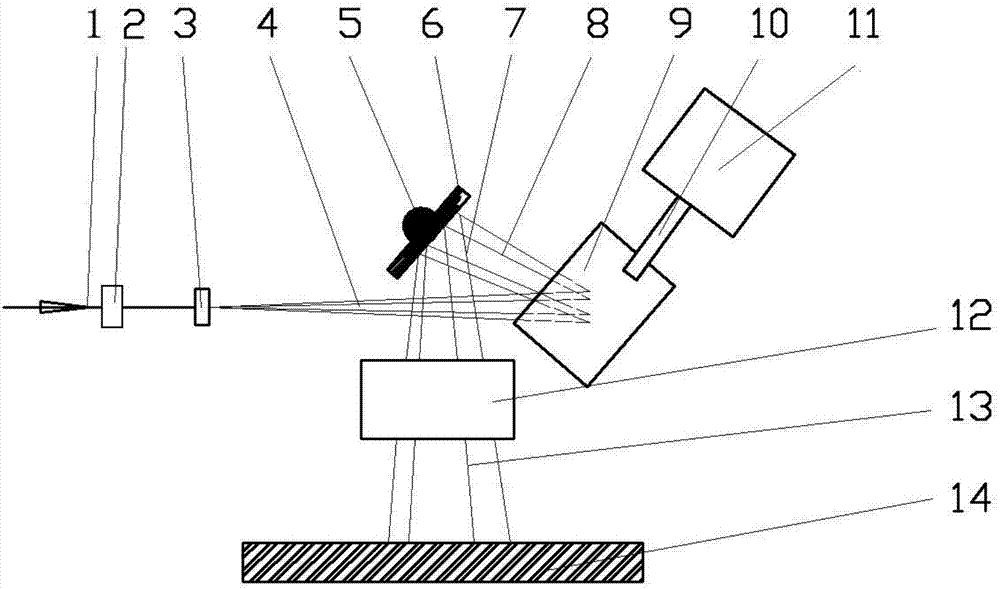

[0054] figure 1 It is a schematic diagram of the structure of the laser beam splitting galvanometer scanning processing device used in the laser marking of the stainless steel light guide plate mask, such as figure 1 As shown: the stainless steel light guide plate mask laser marking device of this embodiment includes an incident light beam 1, a beam control module, a laser beam splitting module 3 and a galvanometer scanning focusing unit. The workpiece 14 to be processed is a stainless steel sheet with a thickness of 200 microns.

[0055] The beam control module includes a laser beam expanding unit 2, and the galvanometer scanning and focusing unit includes a scanning galvanometer and a scanning plan focusing lens. The scanning plan focusing lens includes a common plan scanning focusing lens and a telecentric plan scanning focusing lens. In this embodiment, the scanning plan focusing lens adopts a telecentric plan scanning focusing lens 12, and the telecentric scanning The focal l...

Embodiment 2

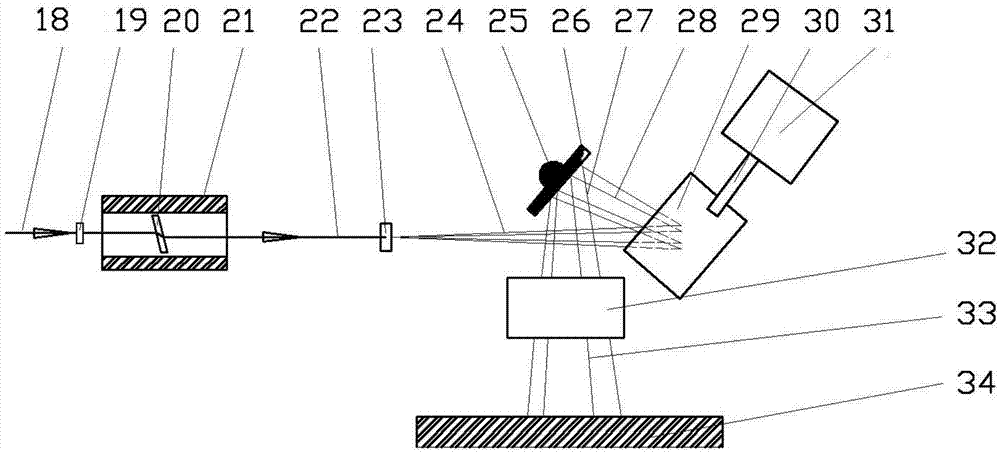

[0062] figure 2 It is a schematic diagram of the structure of a laser beam splitting galvanometer scanning processing device used in silicon wafer drilling according to the present invention, such as figure 2 As shown: including a beam control module, a laser beam splitting module and a galvanometer scanning and focusing module, the workpiece 34 to be processed is a polysilicon wafer with a thickness of 200 microns, which is fixedly installed on a linear moving platform.

[0063] The beam control module of this embodiment includes a laser beam expanding unit 19 and a beam dynamic control unit.

[0064] The incident beam 18 in this embodiment is an incident expanded collimated beam with a diameter of 10 mm. The relevant parameters are as follows: laser wavelength 532 nanometers, beam quality factor less than 1.2, spot roundness greater than 90%, and average power 35 watts , Single-mode Gaussian laser (the transverse field strength is Gaussian distribution), and the pulse repetition...

Embodiment 3

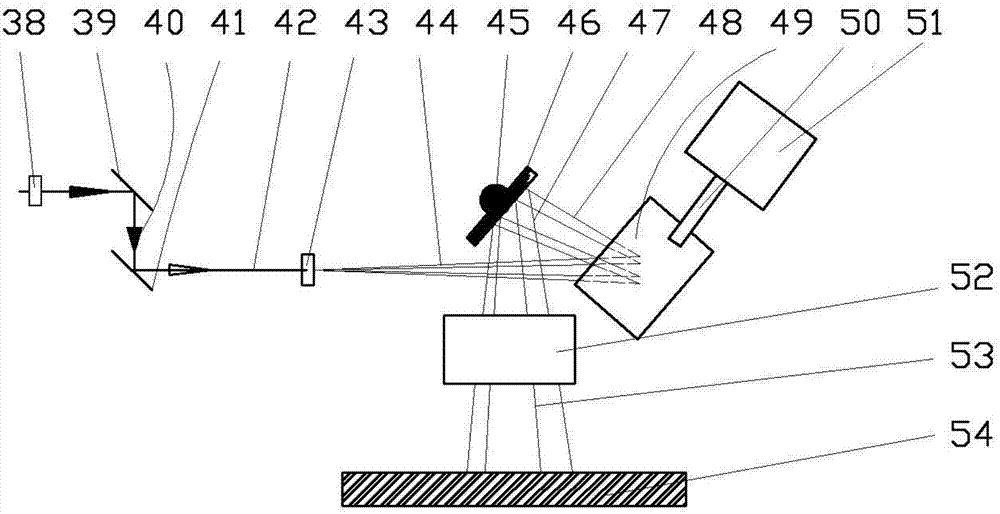

[0075] Such as image 3 Shown is a structural schematic diagram of the application of a laser beam splitting galvanometer scanning processing device in a stainless steel filter screen drilling of the present invention, including a beam control module, a laser beam splitting module, and a galvanometer scanning focusing module. The workpiece to be processed 54 It is a stainless steel sheet with a thickness of 100 microns.

[0076] The incident beam is an incident expanded collimated beam with a diameter of 10 mm, and its relevant parameters are as follows: laser wavelength 532 nanometers, beam quality factor less than 1.2, spot roundness greater than 90%, average power 30 watts, single mode Gaussian laser (the transverse field strength is Gaussian distribution), the pulse repetition frequency is 100 kHz.

[0077] The beam control module of this embodiment includes a laser beam expanding unit 38 and a beam dynamic control unit. The beam dynamic control unit includes a first incident ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com