Copper rod processing line and copper rod processing technology

An assembly line, copper rod technology, applied in lighting and heating equipment, crucible furnaces, furnaces, etc., can solve the problems of insufficient deoxidation, defects, copper rod damage, etc., to improve the quality of copper rods, good compactness, and utilization. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and embodiments.

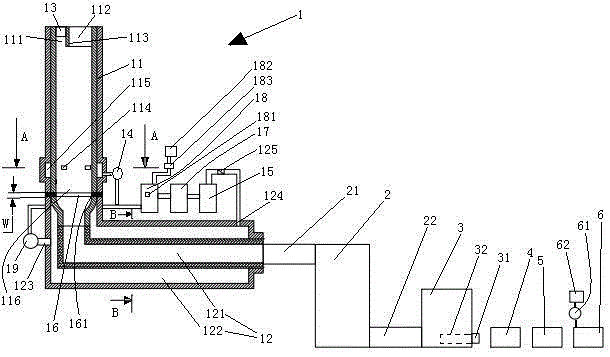

[0033] see figure 1 , a copper rod processing line, including a copper melting furnace 1, a holding furnace 2, a continuous casting machine 3, a corrugated angle cutting machine 4, an edge milling machine 5 and a rolling mill 6, which are arranged in sequence.

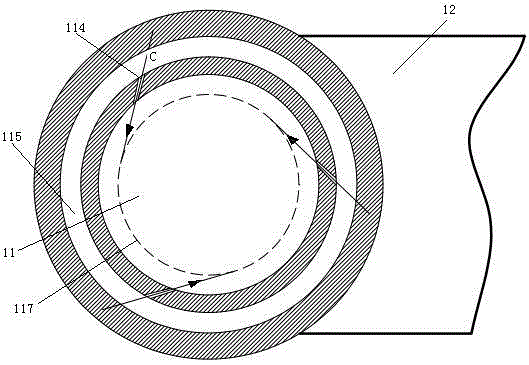

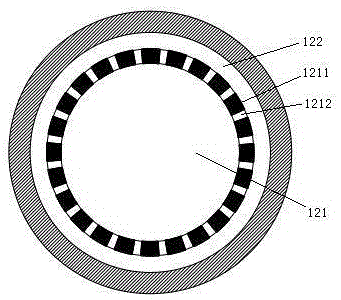

[0034] The copper melting furnace 1 includes a combustion furnace 11 and a reduction tank 12 .

[0035] The combustion furnace 11 is arranged vertically. The upper end of the combustion furnace 11 is provided with a fuel inlet 111 and a copper block input port 112 . The fuel inlet 111 and the copper block input port 112 are separated by a partition wall 113 . The fuel inlet 111 and the copper block input port 112 are arranged side by side. The fuel inlet 111 is fitted with the swirl burner 13 . The beneficial effects of the position of the fuel inlet and the copper block input port are: it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com