Cured film

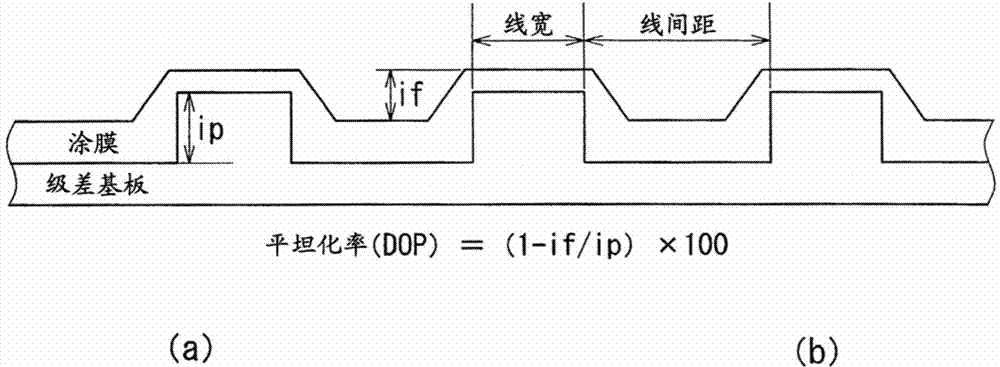

A curing film, thermal curing technology, used in coatings, instruments, optics, etc., can solve problems such as low solubility, reduced planarization and transparency, and difficulty in applying planarization film production lines to achieve high planarization, The effect of high transparency and high solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]

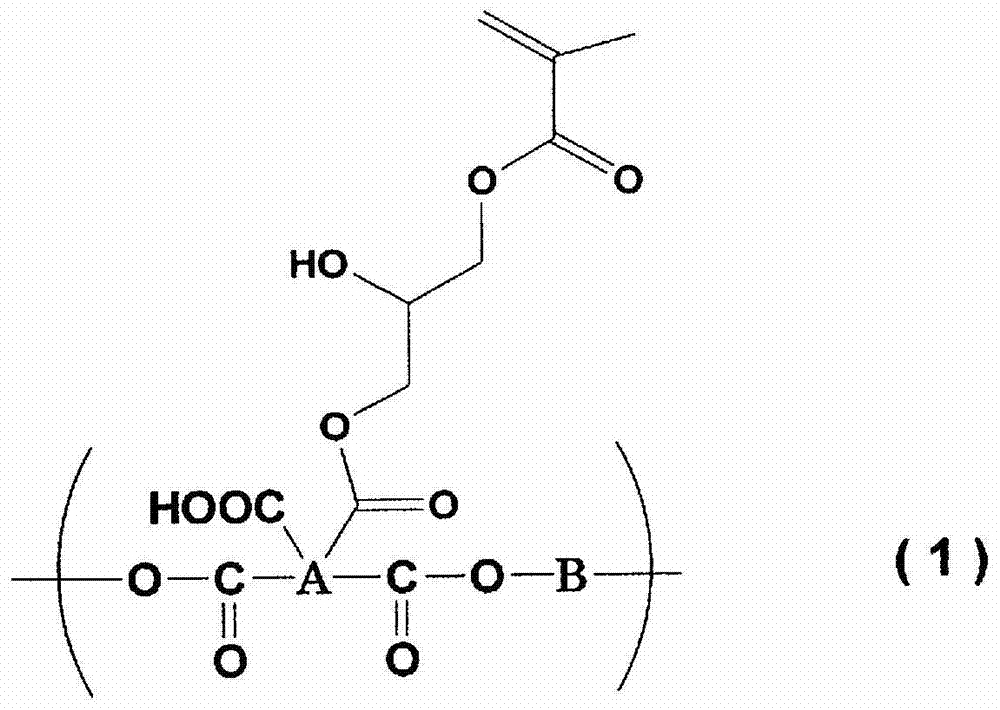

[0044] The polyester polymer of the formula (1) used in the present invention is obtained by making tetracarboxylic dianhydride (acid component) represented by the following formula (i) and the diol compound (diol) represented by the following formula (ii) Alcohol component) is reacted, and then glycidyl methacrylate is added to the generated partial carboxyl groups.

[0045]

[0046] In the above formula, A and B have the same definitions as in the aforementioned formula (1).

[0047] More specifically, the above formula (i) is reacted with formula (ii) to form a polymer (hereinafter also referred to as a specific polymer) comprising a structural unit represented by the following formula (iii), and then glycidyl methacrylate Esters are obtained by appending some of the carboxyl groups of the polymer.

[0048]

[0049] In the above formula, A and B have the same definitions as in the aforementioned formula (1).

[0050]

[0051] In a polyester polymer (herei...

Embodiment

[0100] The following examples are given to illustrate the present invention in more detail, but the present invention is not limited to these examples.

[0101] [Abbreviated symbols used in Examples]

[0102] The meanings of the abbreviations used in the following examples are as follows.

[0103]

[0104] BPDA: biphenyltetracarboxylic dianhydride

[0105] 6FDA: 4,4'-(hexafluoroisopropylidene)phthalic dianhydride

[0106] HBPA: hydrogenated bisphenol A

[0107] HBPDA: hydrogenated biphenyltetracarboxylic dianhydride

[0108] CHDO: 1,4-cyclohexanediol

[0109] GMA: Glycidyl methacrylate

[0110] THPA: 1,2,5,6-tetrahydroxyphthalic anhydride

[0111] BTEAC: Benzyltriethylammonium Chloride

[0112] TPPB: tetraphenyl bromide

[0113] TBC: 3,5-di-tert-butylcresol

[0114]

[0115] CBDA: cyclohexanetetracarboxylic dianhydride

[0116] pDA: p-phenylenediamine

[0117]

[0118] MAA: methacrylic acid

[0119] MMA: methyl methacrylate

[0120] HEMA: 2-Hydroxyethyl me...

Synthetic example 1

[0130] A solution of a specific polymer was obtained by reacting 40.0 g of BPDA, 35.3 g of HBPA, and 0.77 g of BTEAC in 175.7 g of PGMEA at 120°C for 1 hour, then adding 3.31 g of THPA and reacting for 19 hours (solid concentration: 30.0% by mass) (P1). The obtained specific polymer had Mn of 1,100 and Mw of 2,580.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com