The production process of cvc burning cotton, dispersing and co-printing and co-printing with paint color paste

A paint color paste and production process technology, applied in the treatment of textile materials, dyeing methods, liquid/gas/steam textile material treatment, etc., can solve the problem of increasing the difficulty of washing, undeveloped, and dispersion materials that are not resistant to burning cotton pulp, etc. problem, to achieve the three-dimensional effect of the pattern and the contrast enhancement, the process is stable and easy, and the effect of good dry and wet fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Composition of slurry:

[0057] A. Paint color paste is calculated according to mass percentage:

[0058] High temperature paint: 1%

[0059] Imitation active solid slurry: 10%

[0060] Thickener: 1%

[0061] The balance is soft water.

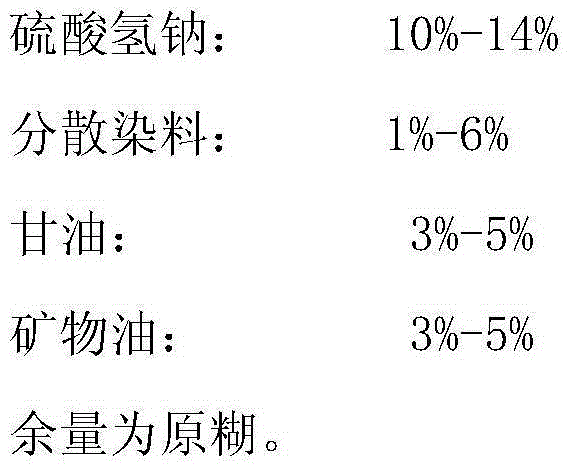

[0062] B. Sintered cotton disperse same pulp is calculated according to mass percentage:

[0063]

[0064]

[0065] Among them, Disperse Yellow was purchased from Baishiji Chemical Industry.

[0066] The implementation method of CVC burning cotton dispersion and printing fabrics together with paint color paste: a. Scrape the adjusted slurry evenly on the fabric with a scraper; b. Move the fabric into the oven (or drying room) and heat it at 150℃ Drying for 3 minutes; c. After drying, steam the fabric in a long-ring continuous steamer at 170°C for 5 minutes; d. Rinse the fabric and wash it with cold running water for 5 minutes in a washing machine; the weight of the fabric and the volume of water are 1:20 Add water in the ratio...

Embodiment 2

[0069] Composition of slurry:

[0070] A. Paint color paste is calculated according to mass percentage:

[0071] High temperature paint: 6%

[0072] Imitation active solid slurry: 25%

[0073] Thickener: 3%

[0074] The balance is soft water.

[0075] B. Burning cotton and dispersing the same pulp are calculated according to the mass percentage:

[0076]

[0077] The implementation method of CVC burning cotton dispersion and printing fabrics together with paint color paste: a. Scrape the adjusted slurry evenly on the fabric with a scraper; b. Move the fabric into the oven (or drying room) and heat it at 150℃ Drying for 3 minutes; c. After drying, steam the fabric in a long-ring continuous steamer at 170°C for 5 minutes; d. Rinse the fabric and wash it with cold running water for 5 minutes in a washing machine; the weight of the fabric and the volume of water are 1:20 Add water in the ratio of dispersant, then add dispersant until the concentration of its aqueous soluti...

Embodiment 3

[0079] Composition of slurry:

[0080] A. Paint color paste is calculated according to mass percentage:

[0081] High temperature paint: 1%

[0082] Imitation active solid slurry: 10%

[0083] Thickener: 1%

[0084] The balance is soft water.

[0085] B. Sintered cotton disperse same pulp is calculated according to mass percentage:

[0086] Sodium bisulfate: 10%

[0087] Disperse Yellow: 1%

[0088] The balance is the original paste EM-228A.

[0089] The implementation method of CVC burning cotton dispersion and printing fabrics together with paint color paste: a. Scrape the adjusted slurry evenly on the fabric with a scraper; b. Move the fabric into the oven (or drying room) and heat it at 150℃ Drying for 3 minutes; c. After drying, steam the fabric in a long-ring continuous steamer at 170°C for 5 minutes; d. Rinse the fabric and wash it with cold running water for 5 minutes in a washing machine; the weight of the fabric and the volume of water are 1:20 Add water in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com