Method for producing hard fiberboard through paper mill sludge

A technology of hard fiberboard and papermaking sludge, applied in fiberboard, papermaking, textiles and papermaking, etc., can solve the problems of low strength, limited supply of short fibers, large dosage, etc., meet the requirements of strength and distortion, and enhance production Degree of cross-linking, the effect of eliminating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method for utilizing papermaking sludge to produce hard fiberboard comprises the following process steps:

[0032] A. Deodorization: add a deodorant to the papermaking sludge for oxidation and deodorization. The deodorant used is chlorine dioxide, the oxidation time is 15 minutes, and the dosage of each agent is 5mg / L;

[0033] B, homogenization: insert crude fiber into the treated sludge in step A and stir to make a slurry evenly, and the mass percentage of crude fiber in the sludge is 0.06%;

[0034] C, forming: placing the slurry made in step B in a fiberboard forming equipment to form a fiberboard;

[0035] D. Drying: The fiberboard formed in step C is dried and shaped under high temperature and high pressure.

[0036] The crude fiber in the step B is selected from textile waste or waste cotton or leftover fiber produced in the production of luggage, and the single length of the crude fiber in the step B is 0.05-20cm.

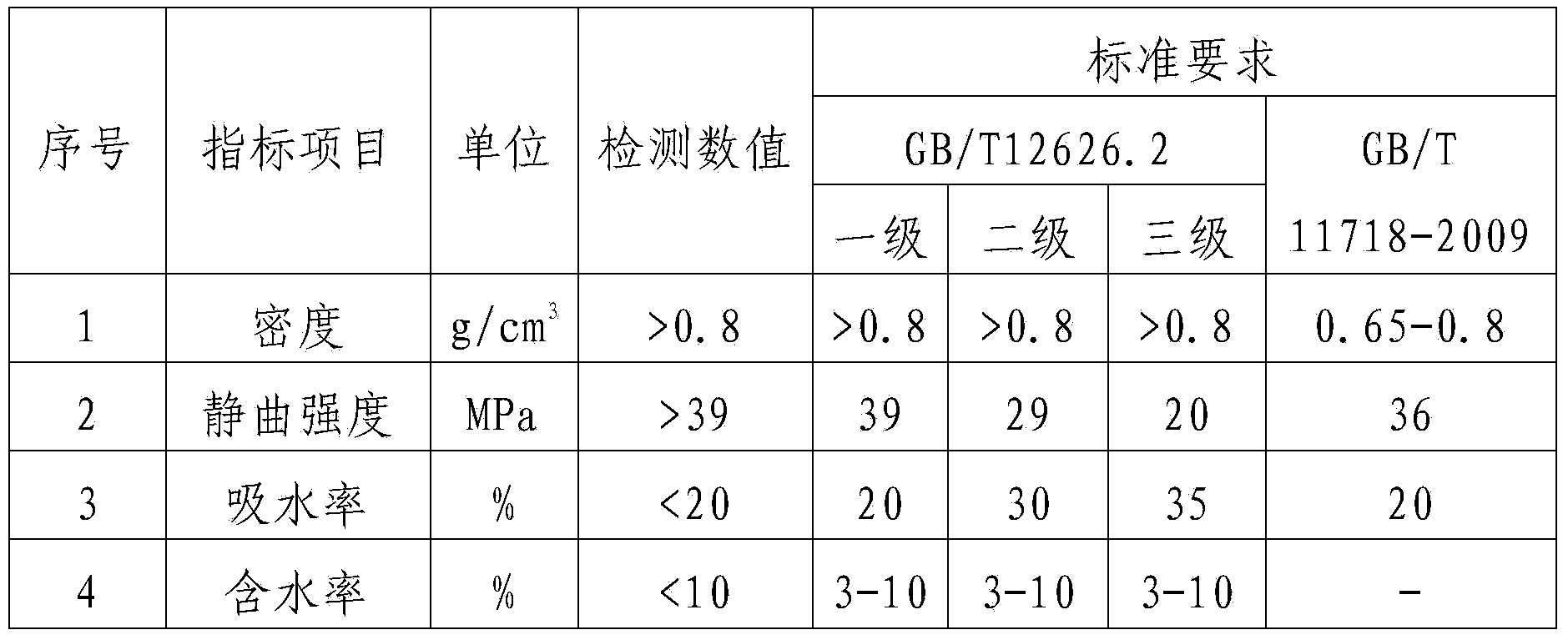

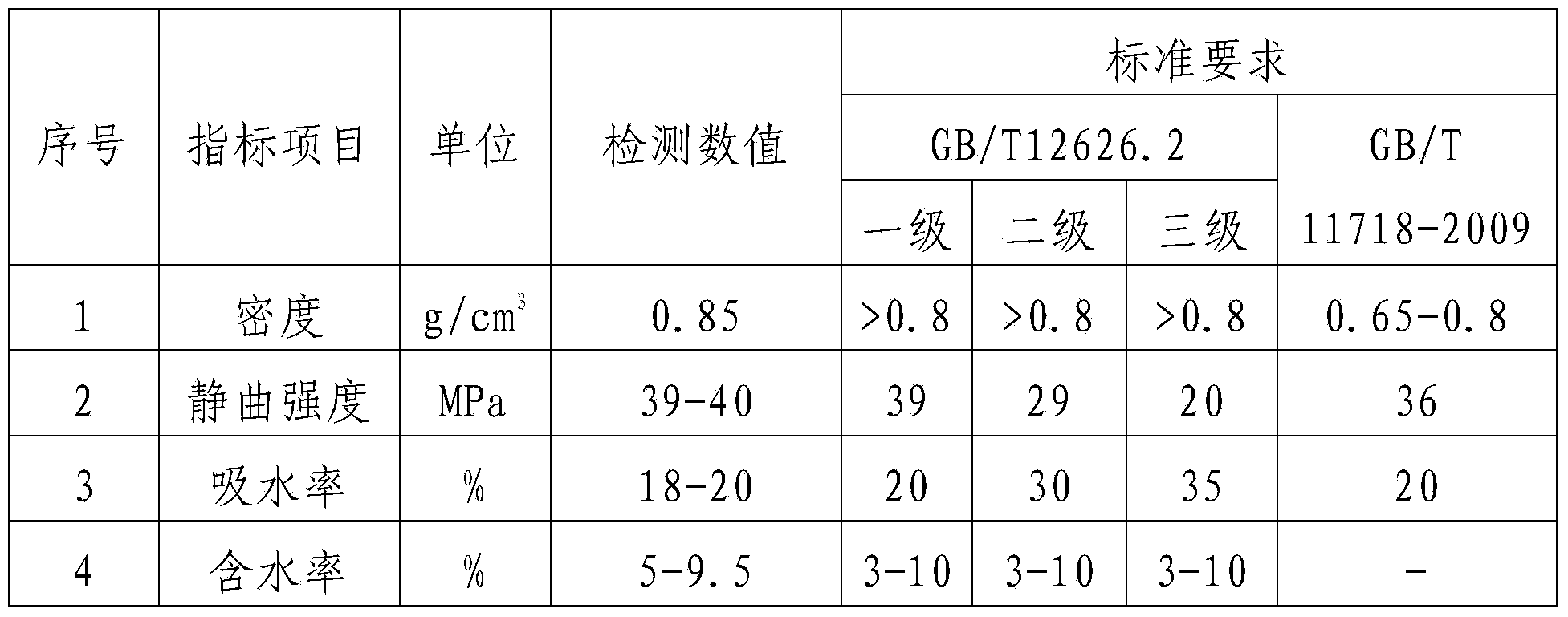

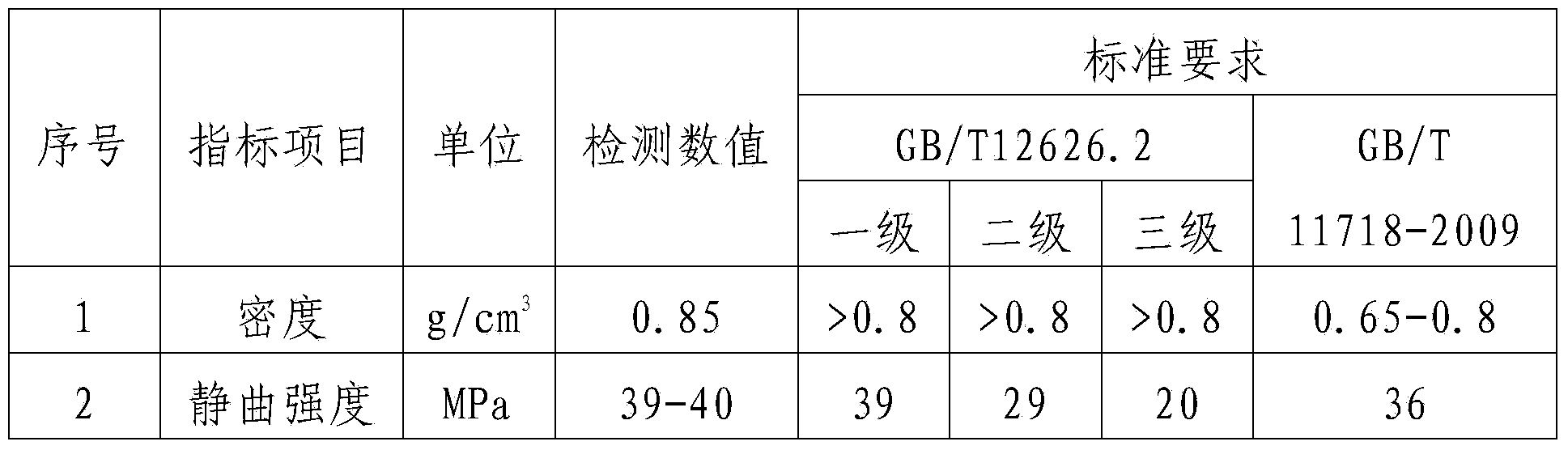

[0037] In the step D, the drying tempera...

Embodiment 2

[0042] The method for utilizing papermaking sludge to produce hard fiberboard comprises the following process steps:

[0043] A. Deodorization: add a deodorant to the papermaking sludge for oxidation and deodorization. The deodorant used is hydrogen peroxide, the oxidation time is 30 minutes, and the dosage of the agent is 20mg / L;

[0044] B, homogenization: insert crude fiber into the treated sludge in step A and stir evenly to make slurry, the mass percentage of crude fiber accounting for sludge is 1.2%;

[0045] C, forming: placing the slurry made in step B in a fiberboard forming equipment to form a fiberboard;

[0046] D. Drying: The fiberboard formed in step C is dried and shaped under high temperature and high pressure.

[0047]The crude fiber in the step B is selected from textile waste or waste cotton or leftover fiber produced in the production of luggage, and the single length of the crude fiber in the step B is 0.05-20cm.

[0048] In the step D, the drying temper...

Embodiment 3

[0054] The method for utilizing papermaking sludge to produce hard fiberboard comprises the following process steps:

[0055] A. Deodorization: add a deodorant to the papermaking sludge for oxidation and deodorization. The deodorant used is ozone, the oxidation time is 25 minutes, and the dosage of the agent is 15mg / L;

[0056] B, homogenization: insert crude fiber into the treated sludge in step A and stir evenly to make slurry, the mass percentage of crude fiber accounting for sludge is 1%;

[0057] C, forming: placing the slurry made in step B in a fiberboard forming equipment to form a fiberboard;

[0058] D. Drying: The fiberboard formed in step C is dried and shaped under high temperature and high pressure.

[0059] The crude fiber in the step B is selected from textile waste or waste cotton or leftover fiber produced in the production of luggage, and the single length of the crude fiber in the step B is 0.05-20cm.

[0060] In the step D, the drying temperature is 170°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Single length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com