Low-temperature-resistant, oil-resistant, torsion-resistant and high-flame-retardant sheath material and preparation method thereof

A high flame-retardant sheath and low-temperature-resistant technology, which is applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of low-temperature resistance, oil resistance, torsion resistance and high flame-retardant performance of cables, and achieve Increase heat aging performance, good mechanical properties and processing properties, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

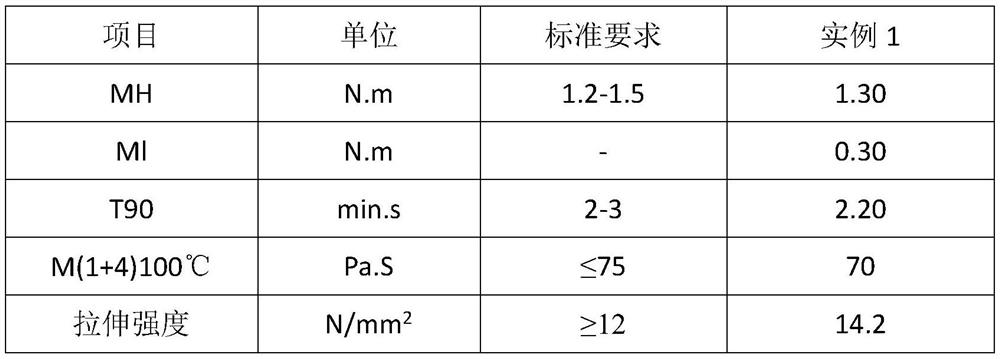

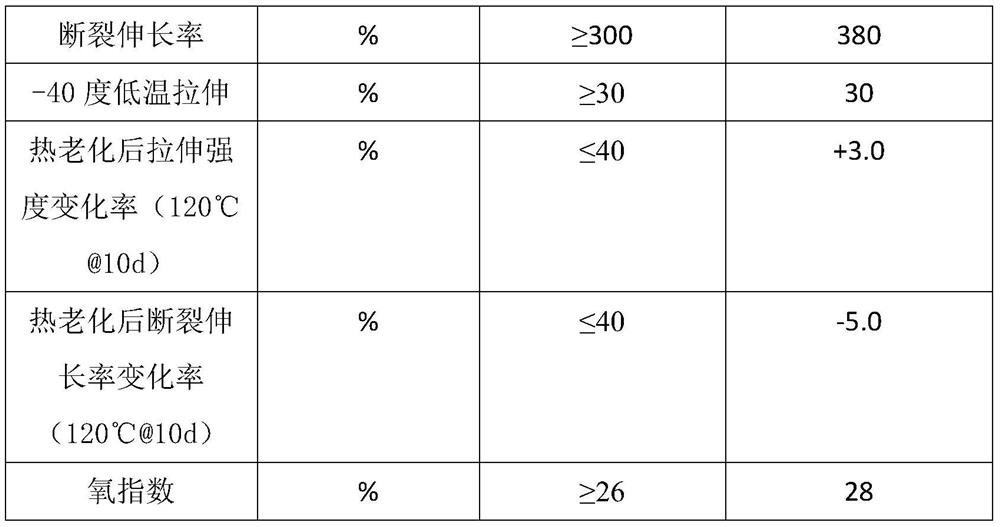

Embodiment 1

[0027] Weigh each component, take by weight and control the properties of each component to meet:

[0028] 60 parts of chlorinated polyethylene, the chlorine content in chlorinated polyethylene is 35%; the Mooney viscosity is 85; chlorinated polyethylene has excellent weather resistance, ozone resistance, chemical resistance and aging resistance, and has good oil resistance , Flame retardancy and coloring performance, ensuring good oil resistance and flame retardancy of the sheath;

[0029] 40 parts of chlorosulfonated polyethylene, the relative density of chlorosulfonated polyethylene is 1.19; the Mooney viscosity is 56; the chlorine content is 35%;

[0030] Chlorosulfonated polyethylene has excellent ozone resistance, atmospheric aging resistance, chemical corrosion resistance, etc., good physical and mechanical properties, aging resistance, heat resistance and low temperature resistance, oil resistance, flame resistance, wear resistance , and resistance to electrical insul...

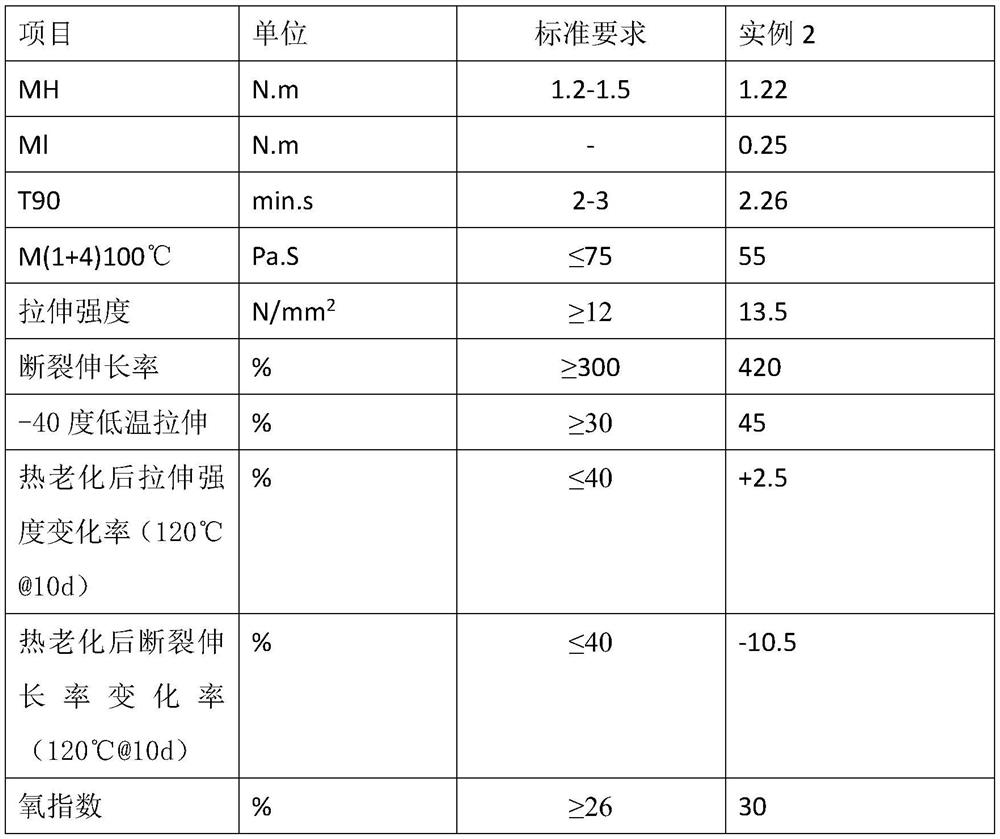

Embodiment 2

[0050] Weigh each component, take by weight and control the properties of each component to meet:

[0051] 80 parts of chlorinated polyethylene, chlorine content in chlorinated polyethylene is 35%; Mooney viscosity is 85;

[0052] 20 parts of chlorosulfonated polyethylene. The relative density of chlorosulfonated polyethylene is 1.19; the Mooney viscosity is 56; the chlorine content is 35%;

[0053] 80 parts of talcum powder;

[0054] 30 parts of calcium carbonate;

[0055] 30 parts of magnesium hydroxide;

[0056] 5 parts of antimony trioxide, adding antimony trioxide as a flame retardant, further increasing the flame retardancy of the sheath;

[0057] 20 parts of carbon black;

[0058] 6 parts of magnesium oxide;

[0059] 5 copies of red pill;

[0060] DOS 15 copies;

[0061] 10 parts of chlorinated paraffin oil;

[0062] 1.5 parts of antioxidant;

[0063] 5 parts of TAIC cross-linking agent;

[0064] 4 parts of dicumyl peroxide.

[0065] The weighed raw material...

Embodiment 3

[0071] Weigh each component, take by weight and control the properties of each component to meet:

[0072] 70 parts of chlorinated polyethylene, chlorine content in chlorinated polyethylene is 35%; Mooney viscosity is 85;

[0073] 20 parts of chlorosulfonated polyethylene, the relative density of chlorosulfonated polyethylene is 1.19; the Mooney viscosity is 56; the chlorine content is 35%;

[0074] 10 parts of ethylene-vinyl acetate copolymer, vinyl acetate content 28%, melt index (190°C, 2.16kg) 6g / 10min, Mooney viscosity 27; ethylene-vinyl acetate copolymer can effectively reduce high crystallinity, Improve flexibility, impact resistance, filler compatibility and heat sealing performance, ensuring good mechanical properties and processing properties of the sheath;

[0075] 80 parts of talcum powder;

[0076] 40 parts of calcium carbonate;

[0077] 20 parts of magnesium hydroxide;

[0078] 5 parts of antimony trioxide;

[0079] 20 parts of carbon black;

[0080] 6 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com