Intelligent vacuum-cycle grouting system

A vacuum circulation and intelligent technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as complex process and unstable grouting quality, and achieve the effect of ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

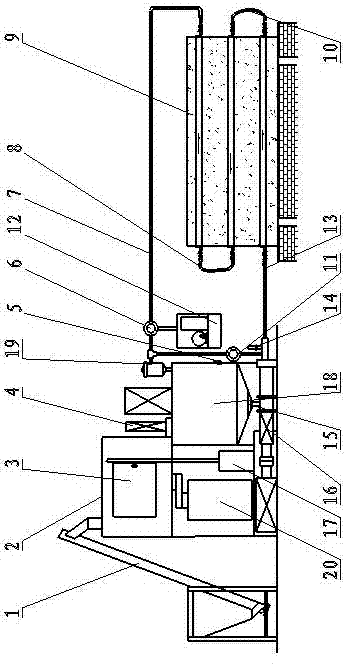

[0012] The system of the present invention includes three sub-systems: (1) Vacuum suction system: vacuum pump 12, vacuum slurry storage tank, program-controlled three-way valve 6; (2) Circulating grouting system: high-speed mixing tank 2, low-speed mixing tank 18. Slurry pump 16, motor 20, electric control valve, grout outlet pipe 13, vacuum / slurry return pipe 7, water storage tank; (3) Intelligent logic control and remote transmission system: PLC program controller, composed of intelligent logic control Various components of the circuit, signal acquisition sensor, two-way wireless transmission module, touch screen.

[0013] A program-controlled three-way valve 6 is arranged on the slurry return pipe, the first port of the program-controlled three-way valve 6 is connected to the vacuum pumping / slurry return pipe 7, the second port is connected to the vacuum pump 12, and the third port is connected to the return pipe; To ensure the tightness, a one-way valve 19 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com