A composite inhibitor for preventing and controlling coal spontaneous combustion and preparation method thereof

A coal spontaneous combustion and inhibitor technology, which is applied in dust prevention, mining equipment, earthwork drilling, etc., can solve the problems of limited inhibition efficiency of physical inhibitors and coal heat accumulation, etc., and achieves environmental friendliness and long life of resistance Long and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

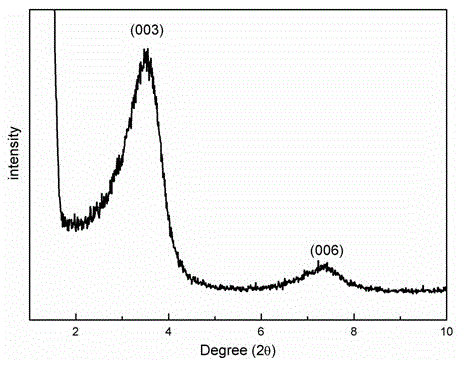

[0022] 1) First weigh 10g of polymer base material-polyvinyl alcohol, add it to 100ml of water, then heat and stir at a constant temperature of 60°C for 60-120min, until a uniform and viscous polymer aqueous solution is obtained. 2) Then add 1 g of ammonium dihydrogen phosphate into 20 ml of water and mix evenly, then mix with the polymer aqueous solution to obtain a polymer solution. 3) 3g surfactant-sodium dodecylbenzenesulfonate is dissolved in 60ml hot water simultaneously, then the hydrotalcite product synthesized by chemical method (referring to figure 1 ) weighed 1g and added it, heated and stirred to obtain a uniformly dispersed mixed solution. 4) After weighing 2g of calcium hydroxide and dissolving it in 20ml of water, add the mixed solution in 3), and disperse evenly to obtain an aqueous solution containing hydrotalcite. 5) Finally, the polymer solution and the aqueous solution containing hydrotalcite are uniformly mixed to obtain a composite inhibitor product.

Embodiment 2

[0024] 1) First weigh 6g of polymer base material-polyvinyl alcohol, add it to 60ml of water, then heat and stir at a constant temperature of 60°C for 60-120min until a uniform and viscous polymer aqueous solution is obtained. 2) Then add 2 g of starch into 20 ml of water and mix evenly, then mix and disperse with the polymer aqueous solution to obtain a polymer solution. 3) At the same time, 3g of surfactant-sodium dodecylbenzenesulfonate was dissolved in 60ml of hot water, and then 1g of the hydrotalcite product synthesized by chemical method was weighed into it, heated and stirred to obtain a uniformly dispersed mixed solution. 4) After weighing 4g of calcium hydroxide and dissolving it in 20ml of water, add the mixed solution in 3), and disperse evenly to obtain an aqueous solution containing hydrotalcite. 5) Finally, the polymer solution and the aqueous solution containing hydrotalcite are uniformly mixed to obtain a composite inhibitor product.

Embodiment 3

[0026] 1) First weigh 6g of polymer base material-polyvinyl alcohol, add it to 60ml of water, then heat and stir at a constant temperature of 60°C for 60-120min until a uniform and viscous polymer aqueous solution is obtained. 2) Then add 4 g of starch into 20 ml of water and mix evenly, then mix and disperse with the polymer aqueous solution to obtain a polymer solution. 3) At the same time, 3g of surfactant-sodium dodecylbenzenesulfonate was dissolved in 40ml of hot water, and then 1g of the hydrotalcite product synthesized by chemical method was weighed into it, heated and stirred to obtain a uniformly dispersed mixed solution. 4) After weighing 2g of magnesium hydroxide and dissolving it in 10ml of water, add the mixed solution in 3) after dissolving, and disperse evenly. 5) After weighing 4g of calcium hydroxide and dissolving it in 20ml of water, add the mixed solution in 4), and disperse evenly to obtain a mixed aqueous solution containing hydrotalcite. 6) Finally, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com