An analyzer for measuring the intrinsic dissolution and dissolution of solid pharmaceuticals

A dissolution and analyzer technology, applied in measurement devices, analysis materials, material analysis by optical means, etc., can solve problems such as particle interference of optical fiber sensors, and achieve the effects of improving mass transfer, improving uniformity, and reducing system deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

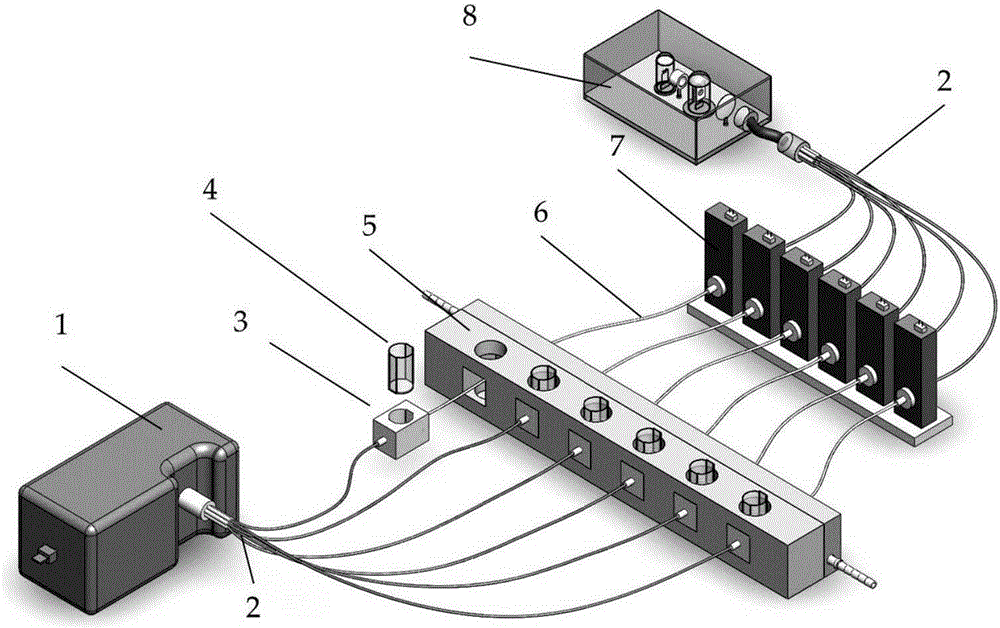

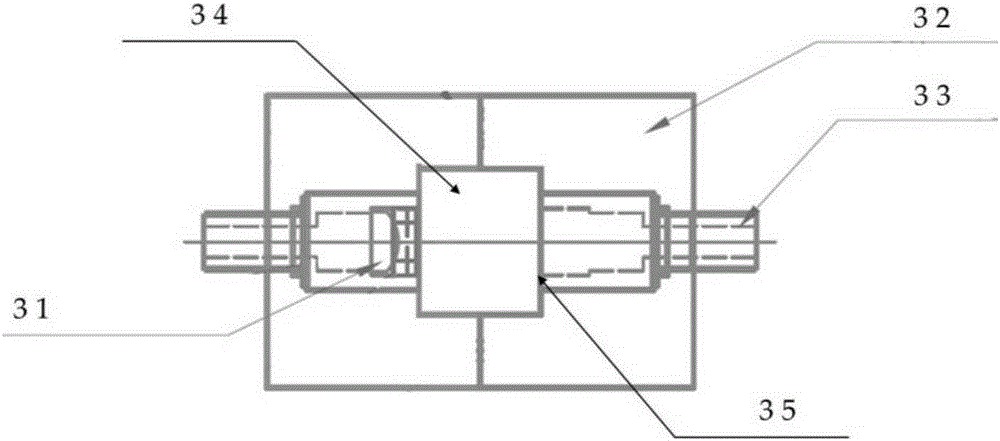

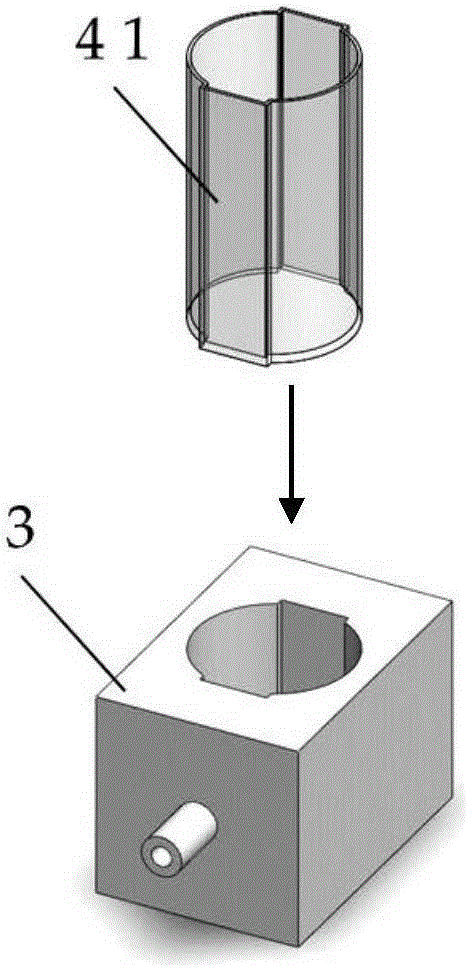

[0049] Such as figure 1 , 2 As shown, the input end of the multi-channel fusion fiber 2 is connected to the light source 8 , and its output end is connected to the input ends of six fiber coupling switches 7 . The output end of each optical fiber coupling switch 7 is connected with the input end of a single-channel optical fiber 6 respectively, and the output end of the single-channel optical fiber 6 is connected with the optical fiber interface 33 of the non-contact detection component main body 32, and the output of the non-contact detection component 3 end is linked with the input end of another multi-channel fusion optical fiber 2, the output end of this multi-channel fusion optical fiber 2 is connected with the detector 1, the non-contact detection part 3 is fixed in the groove of the temperature control bracket 5, and the sample cup 4 It is directly placed in the fixed groove 34 of the non-contact detection part 3, the rotor is placed in the sample cup 4, the temperatur...

Embodiment 2

[0055] Such as Figure 5 As shown, the difference between the analyzer in this embodiment and Embodiment 1 is that the sample cup 4 is a cylindrical sample cup 43, and the cylindrical sample cup 43 is fixed in a circular groove ferrule 92, and the circular groove The ferrule 92 is placed in the fixed groove 34 of the non-contact detection part 3, the rotor is placed in the cylindrical sample cup 43, the temperature control bracket 5 is fixed on the stirrer, and the dissolution of the drug is realized through the stirrer and the rotor. The cylindrical sample cup 43 has a diameter of 10 mm and a height of 100 mm.

[0056] Wherein, the diameter of the rotor is 6mm, and the height is 2mm. The stirrer drives the rotor to rotate in the cylindrical sample cup 43 through the magnetic field, so that the mass transfer of the drug powder is carried out uniformly.

[0057] Additionally, if Image 6 As shown, the sample cup can also be a square sample cup 42 , and the square sample cup ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com