Method for determining coefficient of thermal expansion

A technology of thermal expansion coefficient and measurement method, applied in the direction of thermal expansion coefficient of materials, etc., can solve problems such as large difference in results, complex and expensive instruments, and inability to prepare bulk samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

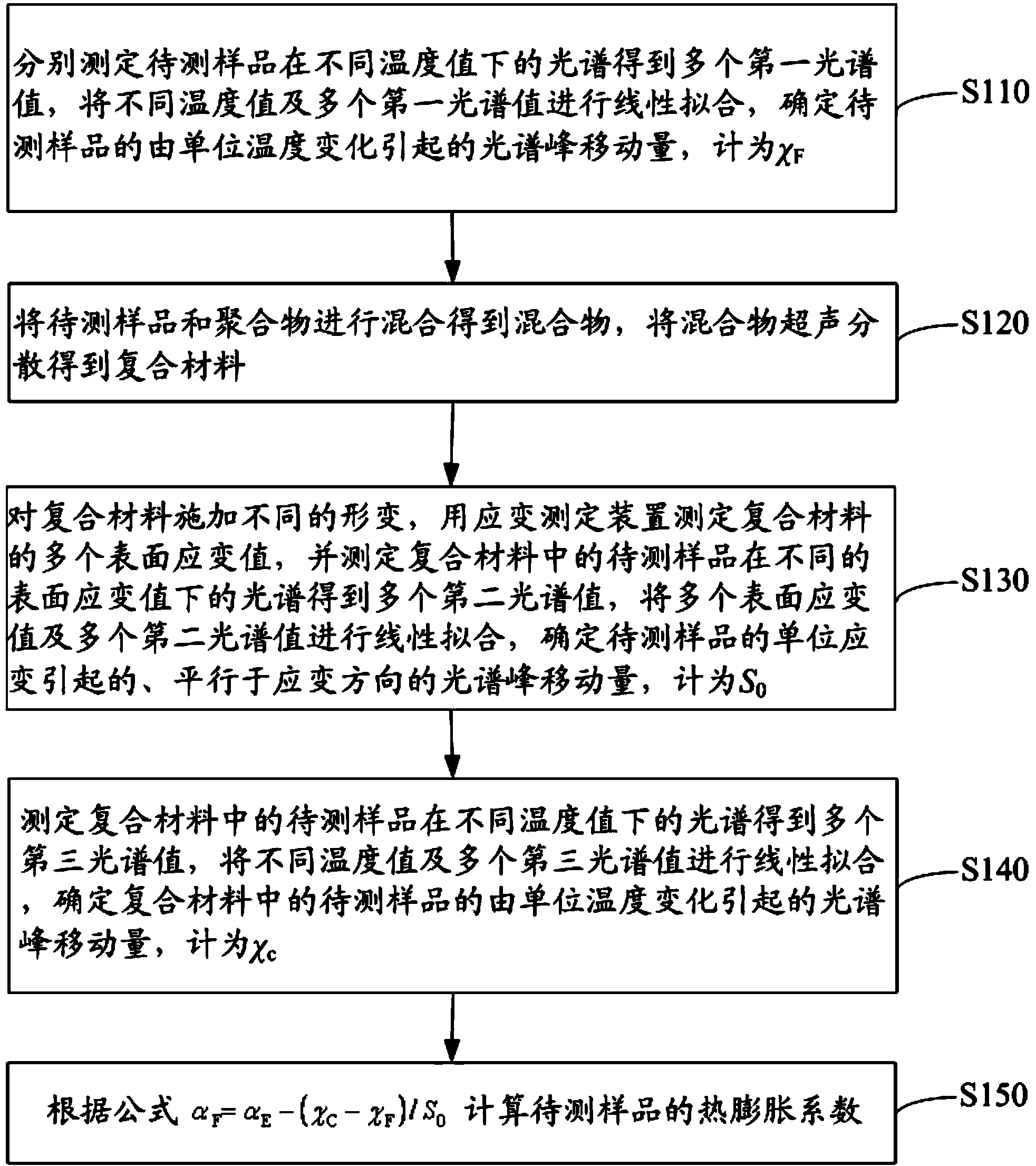

Method used

Image

Examples

Embodiment 1

[0140] Determination of Thermal Expansion Coefficient of Bisphenol A Type Epoxy Resin

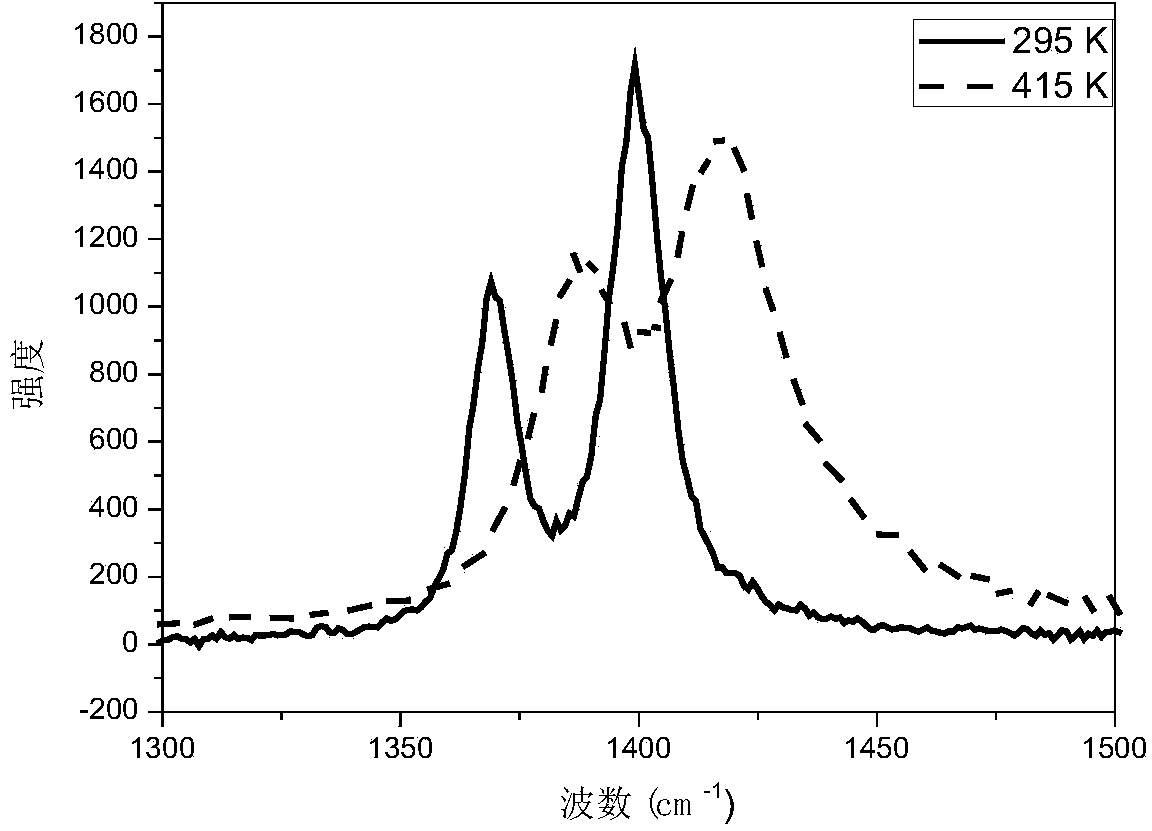

[0141] 1. Place a single alumina fiber in a heating table, place the heating table on an optical microscope stage, and heat the alumina fiber between 22°C and 142°C with a step length of 10°C, using Renishaw2000 to pull The Raman system measures the Raman spectra at different temperatures, and collects the Raman spectra of the alumina fibers at different temperatures with 633nm laser excitation, and obtains 13 first Raman spectral values. Among them, the R1 peaks of alumina fibers at 295K and 415K are as follows image 3 shown. Take 13 temperature values of 22°C, 32°C, 42°C, 52°C, 62°C, 72°C, 82°C, 92°C, 102°C, 112°C, 122°C, 132°C and 142°C as the abscissa, and use the corresponding The 13 first Raman spectrum values of 13 are used as the ordinate, and the 13 temperature values and 13 corresponding first Raman spectrum values are linearly fitted, and the linear diagram is as follo...

Embodiment 2

[0148] Determination of the thermal expansion coefficient of carbon nanotubes

[0149] 1. Place the single-walled carbon nanotubes in a heating stage, place the heating stage on the stage of an optical microscope, and heat the carbon nanotubes between 22°C and 162°C with a step length of 10°C, using Renishaw2000 to pull The Raman system uses 633nm laser excitation to collect Raman spectra of carbon nanotubes at different temperatures, and obtains 15 first spectral values. With 15 temperature values of 22°C, 32°C, 42°C, 52°C, 62°C, 72°C, 82°C, 92°C, 102°C, 112°C, 122°C, 132°C, 142°C, 152°C and 162°C As the abscissa, with the corresponding 15 first spectral values as the ordinate, the 15 temperature values and the 15 corresponding first spectral values are linearly fitted, and the linear diagram is as follows Figure 9 As shown, the linear relationship is ω G’ =2643-0.029T. Determine χ from this linear relationship F , the values are listed in Table 1;

[0150] 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com