Concentrated pig feed, and preparation method and application thereof

A concentrated pig feed, multi-dimensional technology for pigs, applied in the field of concentrated pig feed and preparation, to achieve the effects of rich protein sources, improved palatability, and increased economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

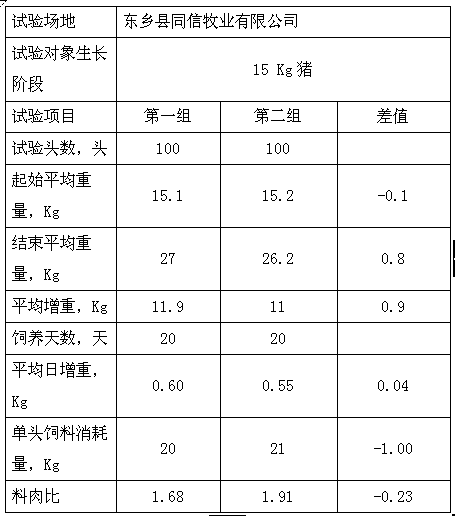

Examples

Embodiment 1

[0032] (1) Material selection and weighing: It is composed of the following parts by weight:

[0033] Ingredients: 48 parts of fish meal, 450 parts of soybean meal, 170 parts of cotton meal, 186 parts of peanut meal, 18 parts of fish oil, 36 parts of calcium hydrogen phosphate, 46 parts of calcium carbonate, 16 parts of salt, 5 parts of lysine;

[0034] Among them: the crude protein value (CP%) requirements of the main ingredients are as follows: fish meal 62, soybean meal 44, cotton meal 41.5, peanut meal 52; mineral requirements are as follows: calcium hydrogen phosphate Ca content 21% P content 16%, calcium carbonate Ca content 38%;

[0035] Excipients: 0.5 part of sweetener, 0.6 part of antioxidant, 1 part of 10% zinc bacitracin, 1 part of multivitamin for pigs, 20 parts of premix.

[0036] The ratio of the said multi-dimensional raw materials for pigs is: 500,000 IU / g VA 50 parts, 510,000 IU / g VD3 5 parts, 50% VE 200 parts, 94% VK3 8 parts, 98% VB1 5.9 parts, 98% VB2 25 parts, 9...

Embodiment 2

[0057] Example 2: Consists of the following parts by weight:

[0058] Ingredients: 45 parts fish meal, 480 parts soybean meal, 160 parts cotton meal, 200 parts peanut meal, 15 parts fish oil, 40 parts calcium hydrogen phosphate, 45 parts calcium carbonate, 20 parts salt, 4 parts lysine;

[0059] Excipients: 0.55 parts of sodium cyclamate, 0.55 parts of antioxidants, 1.2 parts of 10% zinc bacitracin, 0.8 parts of multivitamin for pigs, 22 parts of premix.

[0060] Refer to Example 1 for other raw material requirements and preparation methods.

Embodiment 3

[0061] Example 3: Consists of the following components in parts by weight:

[0062] Main ingredients: 55 parts of fish meal, 420 parts of soybean meal, 180 parts of cotton meal, 170 parts of peanut meal, 20 parts of fish oil, 30 parts of calcium hydrogen phosphate, 50 parts of calcium carbonate, 15 parts of salt, 6 parts of lysine;

[0063] Excipients: 0.45 parts of sodium cyclamate, 0.65 parts of antioxidants, 0.8 parts of 10% zinc bacitracin, 1.2 parts of multivitamins for pigs, 18 parts of premix.

[0064] Refer to Example 1 for other raw material requirements and preparation methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com