Special daily ration for lean brood sow and fabrication method thereof

A technology for lean meat and sows, applied in applications, animal feed, animal feed, etc., can solve the problems of not being able to feed pigs directly, poor palatability, coarse silage feed, etc., to increase feed intake and digestion and absorption rate, Promote peristalsis and improve the effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

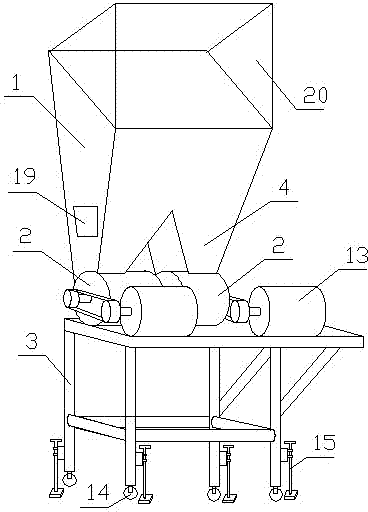

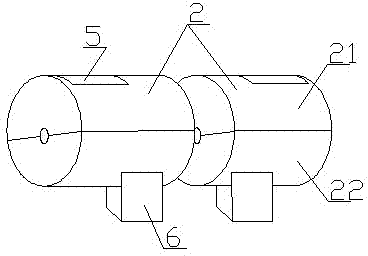

[0042] Example 1: High-efficiency pulverizer dedicated to green storage whole plant corn

[0043] Such as Figure 1-4 As shown, a high-efficiency pulverizer for whole plant corn in green storage includes a feed hopper 1, a pulverizing box 2, a driving device and a frame 3, a pulverizing mechanism is arranged in the pulverizing box 2, and the pulverizing box 2 and the driving The devices are all fixedly arranged on the frame 3 . There are two crushing boxes 2, the lower end of the feed hopper 1 is provided with two feeding outlets 4, and the upper parts of the two crushing boxes 2 are provided with a crushing inlet 5, and the two feeding outlets 4 are connected to the The pulverizing inlets 5 of the two pulverizing boxes 2 are connected respectively, and pulverizing outlets 6 are provided at the lower parts of the pulverizing boxes 2 .

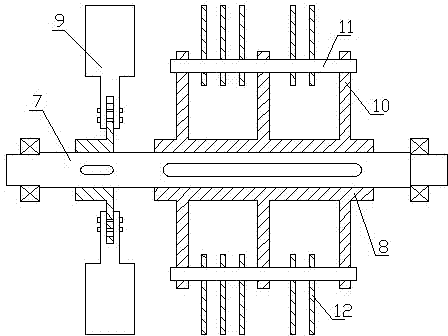

[0044] The crushing mechanism includes a blade holder 8 and a rotating shaft 7. The two ends of the rotating shaft 7 stretch out from the c...

Embodiment 2

[0054] (1) Harvesting: The harvesting time of the whole plant corn should be from the middle stage of corn kernel milk ripening to the early stage of wax ripening, or when the real embryo line (milk line) of corn kernels reaches 1 / 2, and some corn seeds have pits; when harvesting The stubble height should be controlled at 15~20cm;

[0055] (2) Transportation: After corn stalks are harvested, they are required to be transported to the green storage yard immediately;

[0056] (3) Short cutting: the corn stalks transported are cut into 5cm after being cut by the cutting machine;

[0057] (4) High-efficiency crushing: After the cutting is short, it is sent to a high-efficiency grinder, and after the high-speed cutting of the cemented carbide crushing blade at a speed of 1470r / min, the whole corn stalks form particles with a length of 0.5cm;

[0058] (5) Filling and compacting: Immediately fill the crushed raw materials into the fermentation tank. The moisture content of green sto...

Embodiment 3

[0060] Example 3 Diet preparation

[0061] Pre-pregnancy stage lean breeding sows, formula (weight ratio): 30% of silage whole plant corn feed (according to air-dry matter), 45% of corn, 15% of soybean meal, 5.9% of bran, 0.1% of phytase ( Beijing Challenge Group), premix 4% (Shandong Anchi Group); control group formula: corn 55%, soybean meal 16%, bran 25%, premix 4% (Shandong Anchi Group).

[0062] For lean breeding sows in the late pregnancy, formula (weight ratio): 20% corn feed for whole silage (according to air-dry matter), 45% corn, 20% soybean meal, 8.9% bran, and 0.1% phytase (Beijing Challenge Group), soybean oil 2%, premix 4% (Shandong Anchi Group); control group formula: corn 60%, soybean meal 20%, bran 14%, soybean oil 2%, premix 4% (Shandong Anchi Group) group).

[0063] Preparation and use method: Calculate the dosage based on the water content of the silage feed. According to the formula ratio, first add the silage feed into the mixer, and add other raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com