Functional film composite particle, manufacturing method and filter stick formed by functional film composite particle

A technology of composite particles and functional membranes, applied in e-liquid filter elements, applications, tobacco, etc., can solve the problems of large-scale application of filter sticks or cigarette filters, and achieve natural fragrance moisturizing, anti-counterfeiting and identification, and particle formation good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

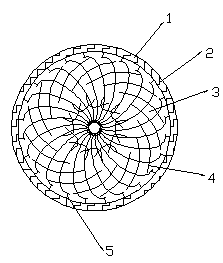

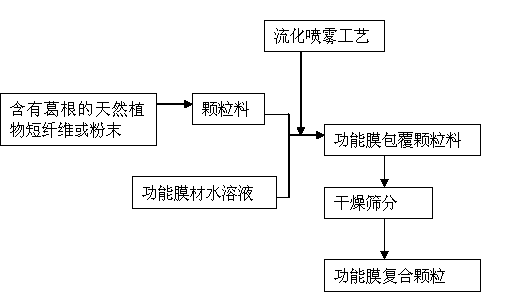

[0039] like figure 1 The functional film composite particles shown are composed of the particle material 3 and the functional film 1 wrapping the particle material 3 through the action of hydrogen bonds (5). Granular material 3 accounts for 90% by weight, functional film 1 accounts for 8% by weight, and other components account for 2% by weight; the granular material 3 is made of natural plants containing kudzu root or burdock fiber 4; functional film 1 is polyvinyl alcohol, chitosan A blend compound of sugar and gelatin, in which the ratio of polyvinyl alcohol and chitosan is 0.5:1; the size of the functional film composite particles is 30 mesh to 60 mesh.

example 2

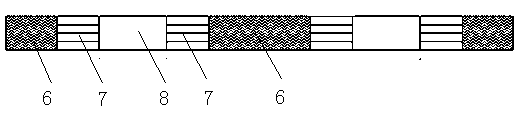

[0041] like image 3 Filter rods of functional membrane composite particles are shown. First, the functional membrane composite particles described in Example 1 are added to the cellulose acetate tow to make the functional membrane composite particle filter rod segment 6, wherein the application amount of the functional membrane composite particles is 1 mg / mm; another groove Filter rod section 7 and ordinary acetate filter rod section 8; the three sections are connected into one body, and the periphery is wrapped with synthetic paper to form a ternary composite filter rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com