Combined packer filtering device

A combined packing and filtration device technology, applied in the directions of loose filter material filter, filtration separation, gravity filter, etc., can solve the problem of unsatisfactory filtration speed, etc., and achieve light weight, convenient installation and transportation, and large water treatment capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below with the best embodiment.

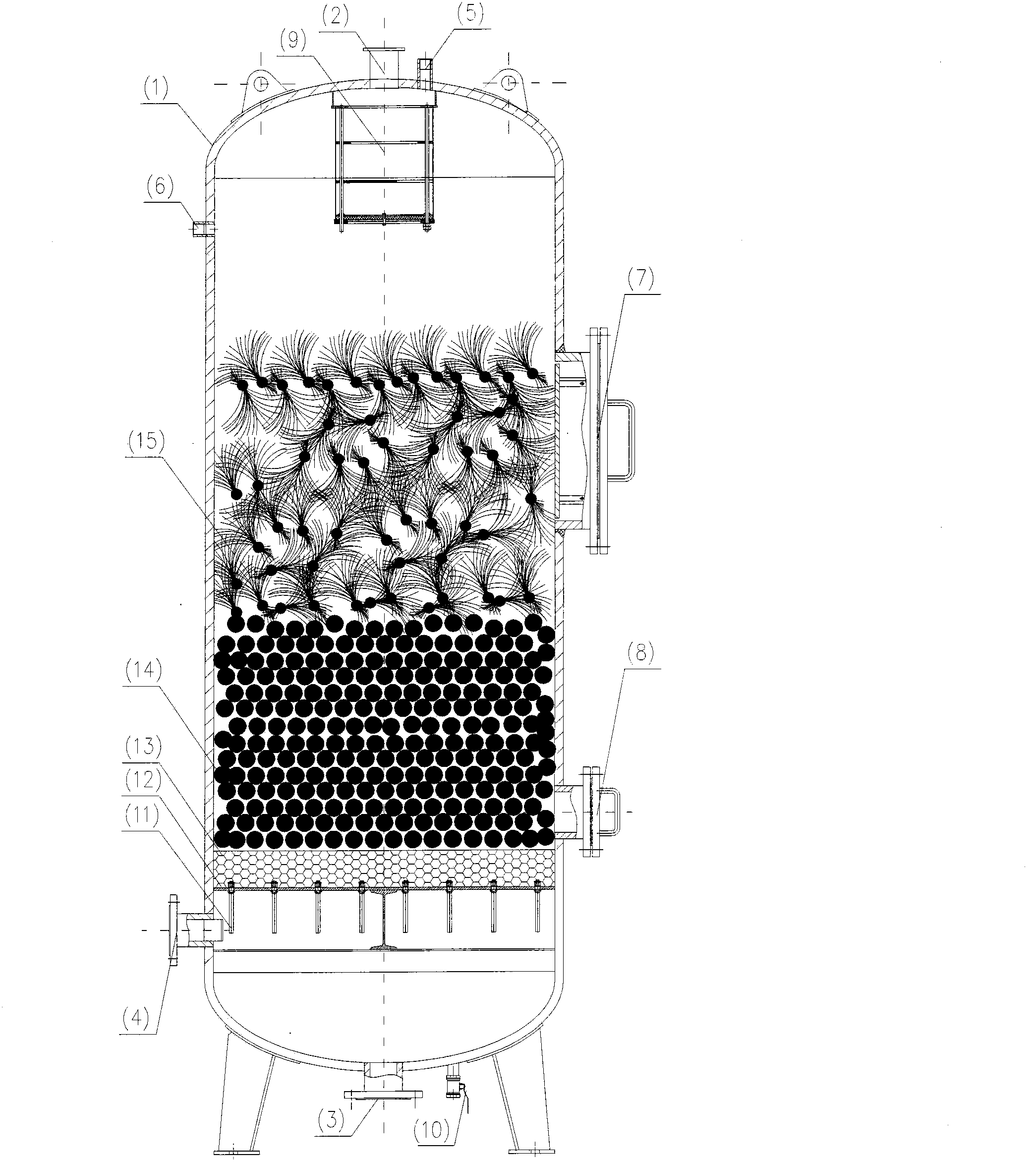

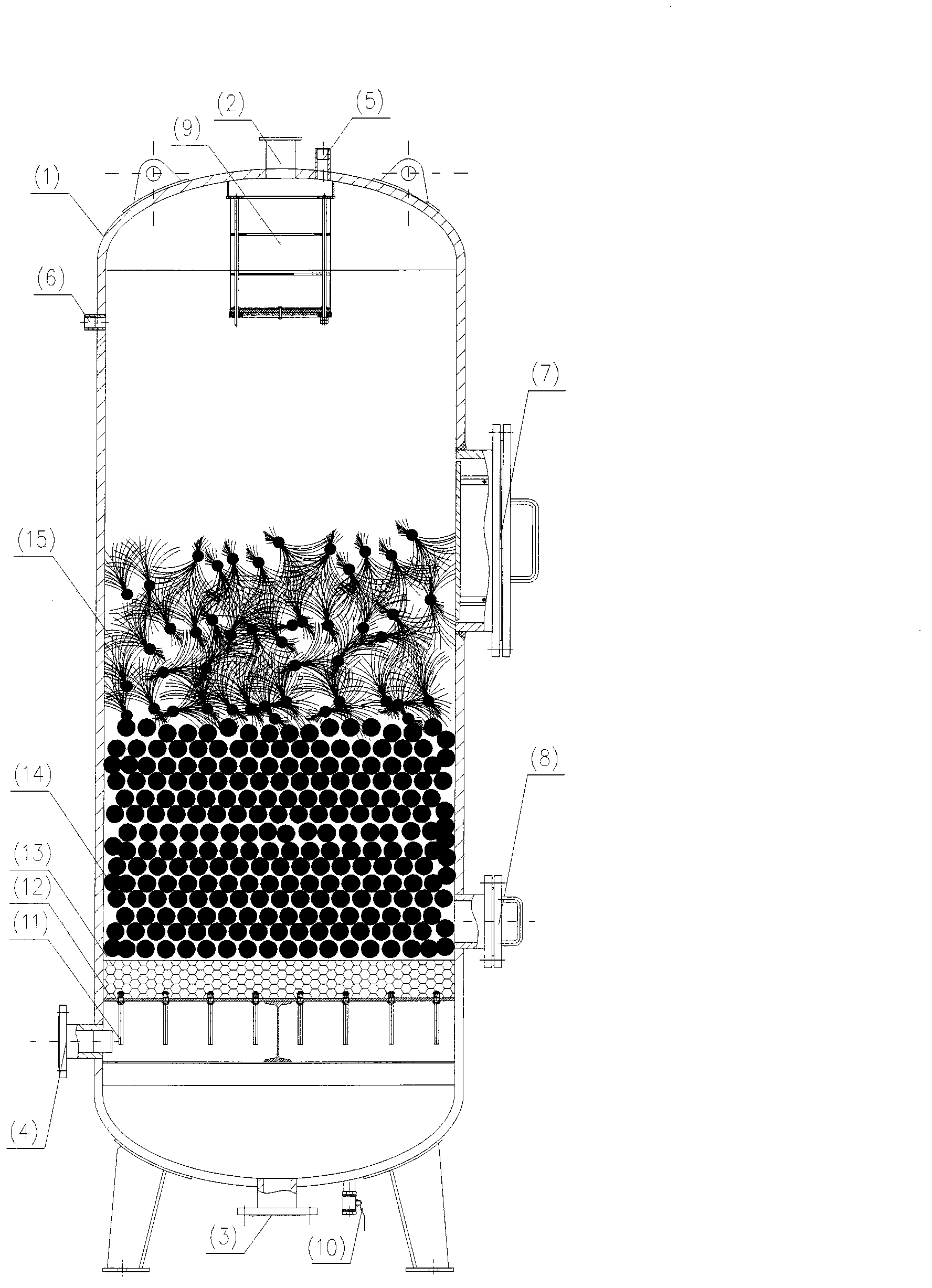

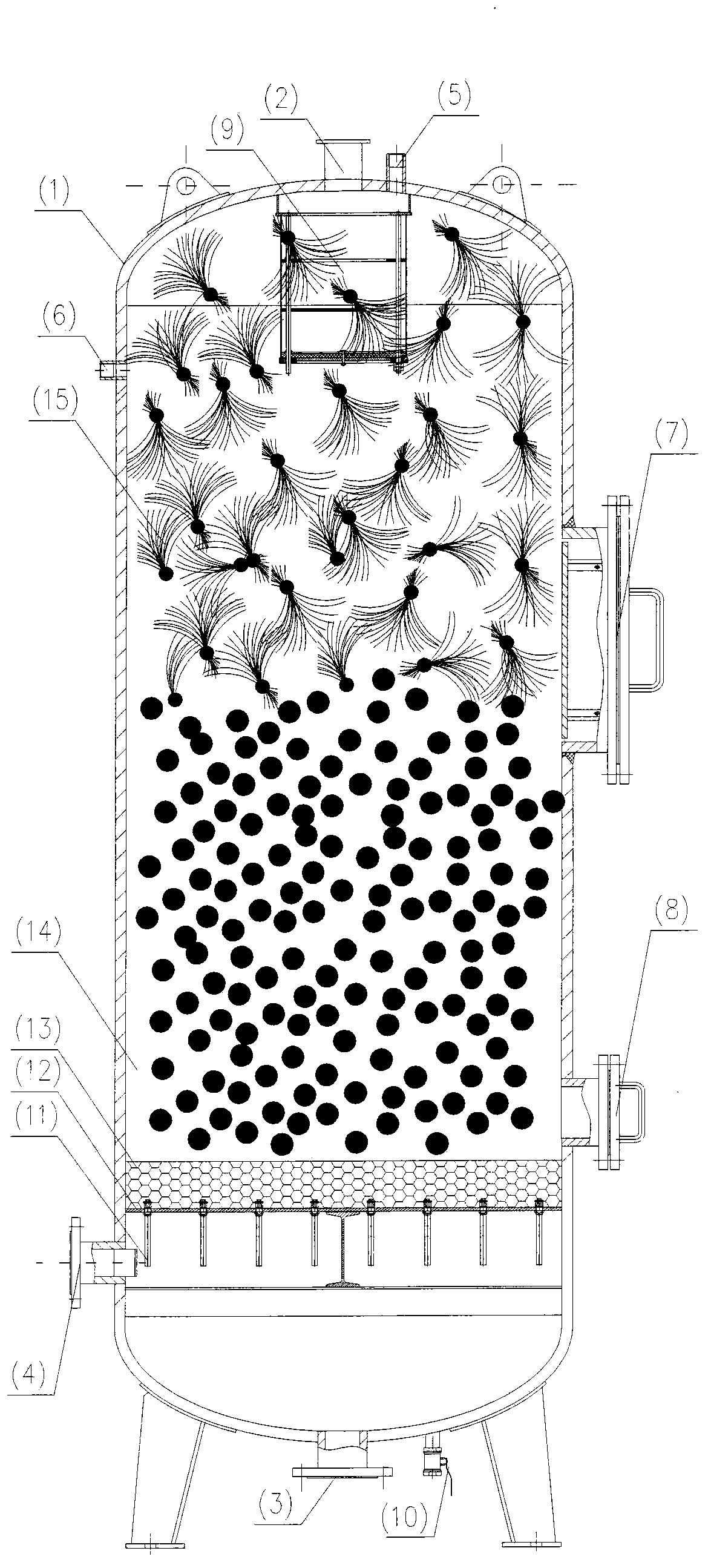

[0012] Such as figure 1 A combined packing filtering device shown includes a body (1), a raw water inlet (2), a filter outlet (3), an air inlet (4), an exhaust port (5), a pressure gauge interface (6 ), inspection and inspection manhole (7), outlet (8), water distributor (9), emptying valve (10), filter head (11), filter plate (12), cobblestone supporting layer (13) , fiber ball packing (14), fiber tow packing (15) and supporting brackets, etc.

[0013] The upper part of the filter device is equipped with a water distributor (9), which is in the shape of a circular wedge-shaped net barrel. There are several water distribution plates in the middle, surrounded by a combination of wedge-shaped nets, which distributes water evenly during filtration, and collects recoiled gas and water in time during recoil. Water intercepts the filling and does not flow out; the side of the main body (1) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com