Air cleaning agent and preparation method thereof

A technology of air purifiers and oxides, applied in chemical instruments and methods, botanical equipment and methods, separation methods, etc., can solve problems such as failure to promote catalytic efficiency, unsatisfactory harmful gas treatment results, and low catalytic efficiency , to achieve the effects of uniform microstructure distribution, easy-to-master technical operation, and mature synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of described air cleaner comprises the following steps:

[0027] (1) Dissolve lactulose-oligosaccharide or glucose, cerium nitrate or lanthanum nitrate, and acrylamide or crotonamide in water to obtain a solution, in which lactulose-oligosaccharide or glucose, cerium nitrate or lanthanum nitrate, acrylamide or butene The molar concentration (mol / L) of the aqueous solution of each component of the amide is: 0.01~1, 0.015~1, 0.02~1, adjust the pH value to 8~12 with urea or ammonia water to obtain a colloid, stir for 3~12 hours, and React at 120-300°C for 10-120 hours, filter to obtain the precipitate, wash the precipitate 5-8 times with water, wash with absolute ethanol 5-8 times, dry at 80°C for 4-8 hours, then dry at 450-600°C Calcining at lower temperature for 6 to 24 hours to obtain a spherical carrier;

[0028] (2) Dissolve the soluble salt of active metal in water to make solution A, the molar concentration (mmol / L) of active metal in solutio...

Embodiment 1

[0032] Embodiment 1: air cleaner: Pt / CeO 2 : 0.2% Pt loading

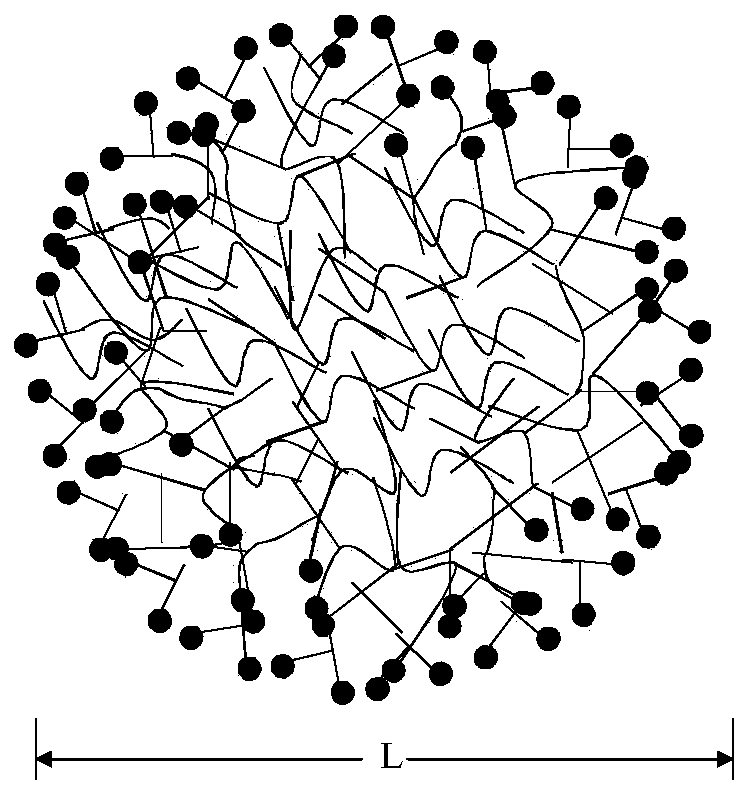

[0033] (1) Dissolve glucose, cerium nitrate and crotonamide in water to obtain a solution, wherein the aqueous molar concentrations (mol / L) of the components of glucose, cerium nitrate and crotonamide are: 0.025, 0.03, 0.03, respectively, Adjust the pH value to 9 with ammonia water to obtain a colloid, stir for 4 hours, react at 140°C for 4 hours, filter to obtain a precipitate, wash the precipitate with water 6 times, wash with absolute ethanol 6 times, and dry at 80°C for 5 hours , calcined at 500°C for 10 hours to obtain bright yellow spherical carrier CeO 2 , the microscopic morphology of the spherical carrier is as follows figure 2 shown;

[0034] (2) The soluble salt of the active Pt metal (H 2 PtCl 6 ) was dissolved in water to make solution A, the molar concentration (mmol / L) of the active metal in solution A was 0.1, the spherical carrier prepared in step (1) was put into solution A and stirred to ob...

Embodiment 2

[0036] Embodiment 2: air cleaner: Pt / CeO 2 : 1.0% platinum loading

[0037] (1) Dissolve glucose, cerium nitrate and crotonamide in water to obtain a solution, wherein the molar concentrations (mol / L) of the aqueous solutions of the components of glucose, cerium nitrate and crotonamide are: 0.1, 0.11, 0.13, respectively, Adjust the pH value to 10 with ammonia water to obtain a colloid, stir for 10 hours, react at 200°C for 40 hours, filter to obtain a precipitate, wash the precipitate with water 6 times, wash with absolute ethanol 6 times, and dry at 80°C for 5 hours , calcined at 600°C for 6 hours to obtain bright yellow spherical carrier CeO 2 ;

[0038] (2) The soluble salt of the active Pt metal (H 2 PtCl 6 ) was dissolved in water to make solution A, the molar concentration (mmol / L) of the active metal in solution A was 0.5, the spherical carrier prepared in step (1) was put into solution A and stirred to obtain suspension B, The mass ratio of the active metal to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com