High-wall compact high-speed precision vertical machining center

A vertical machining center, compact technology, applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low precision, poor overall rigidity, old structure, etc., achieve high metal removal rate and improve rigidity State, the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

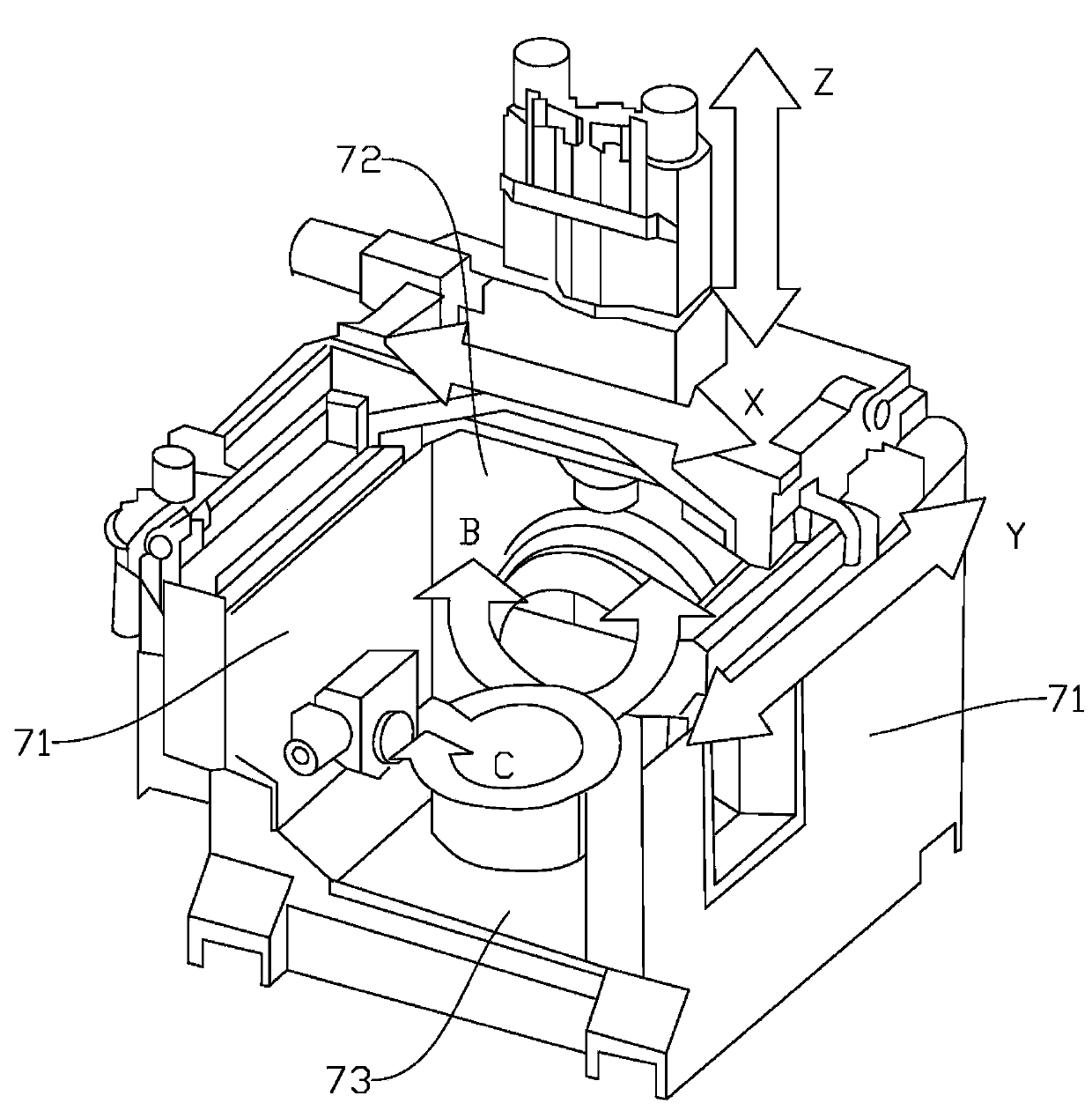

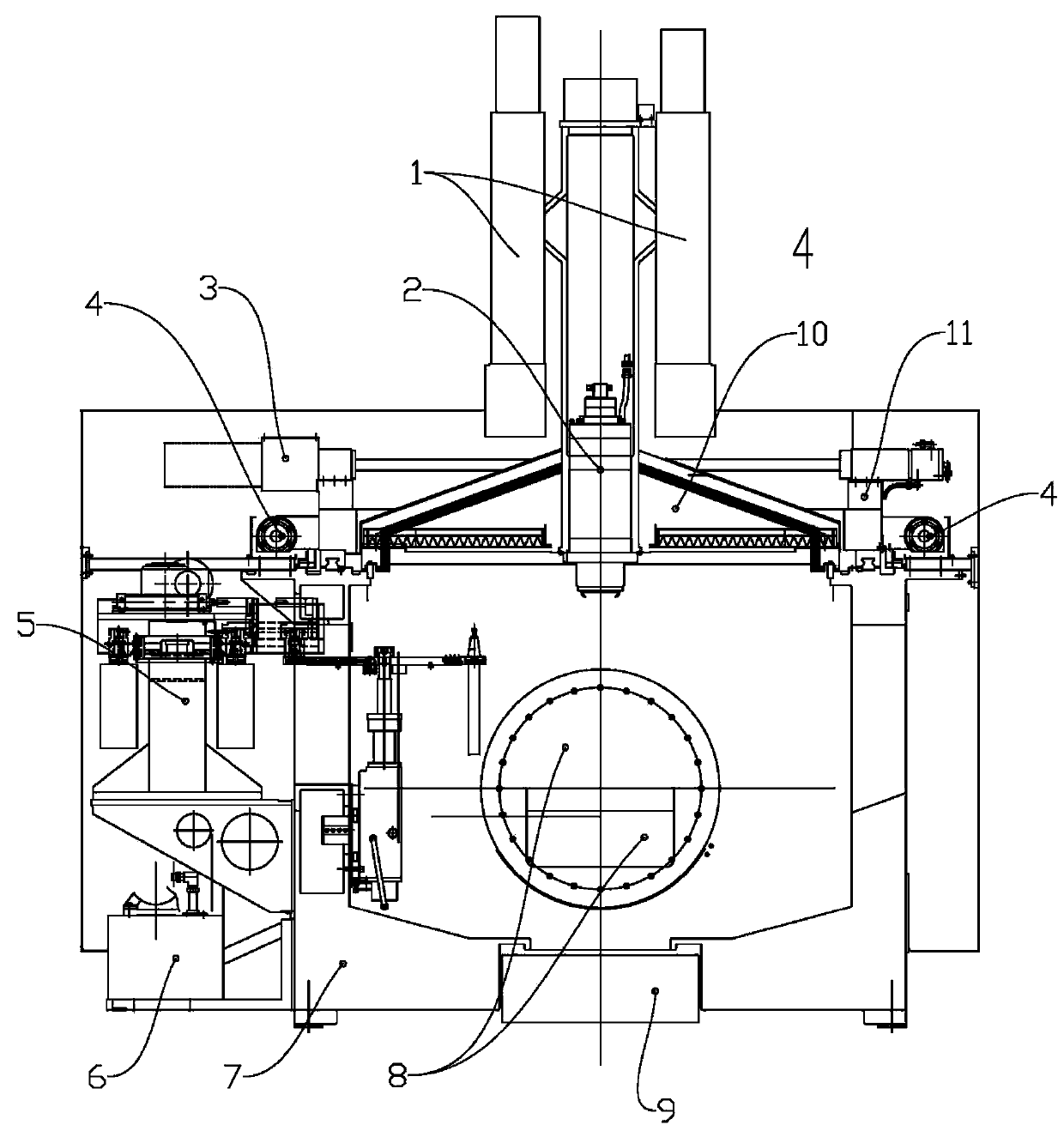

[0027] like figure 1 , 2 , 3, the high-wall compact high-speed precision vertical machining center includes a spindle box 2, an oil tank 6, a tool magazine 5, a bed base 7, an X-direction feed mechanism 3, a Y-direction feed mechanism 4, and a Z-direction feed mechanism. Giving mechanism 1; Also comprise protective cover 20; Described main shaft box 2 comprises main shaft housing and main shaft; Its special feature is:

[0028] The bed base 7 includes a box-type structure formed by sealing and connecting three vertical walls and a chassis 73; the three vertical walls are respectively two side vertical walls 71 and a rear vertical wall 72; the X-direction feed mechanism 3 is arranged on the The top of the rear vertical wall 72; the Y feed mechanism 4 is arranged on the top of the side vertical wall 71, and the Z feed mechanism 1 is also arranged on the top of the rear vertical wall 72;

[0029] The machining center also includes a B, C-axis double-swing axis workbench 8 equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com