Marine propeller

A technology for marine propellers and blades, which is applied in the direction of rotating propellers and rotary propellers, can solve the problems of aggravating propeller metal corrosion and hull vibration, it is difficult for propellers to form reverse power, and it is difficult to improve propeller efficiency, so as to save raw materials, The effect of reducing the vibration of the hull and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

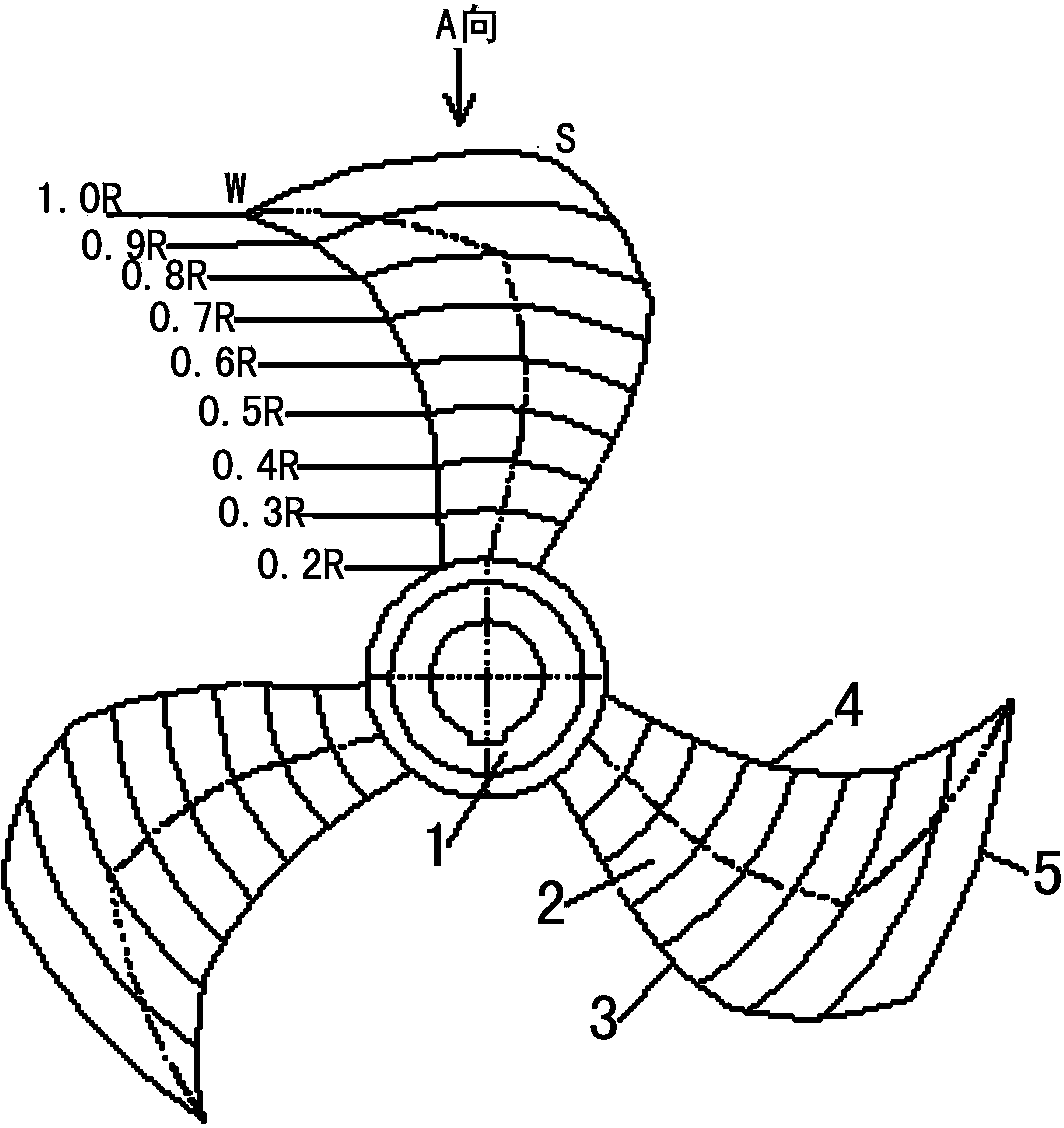

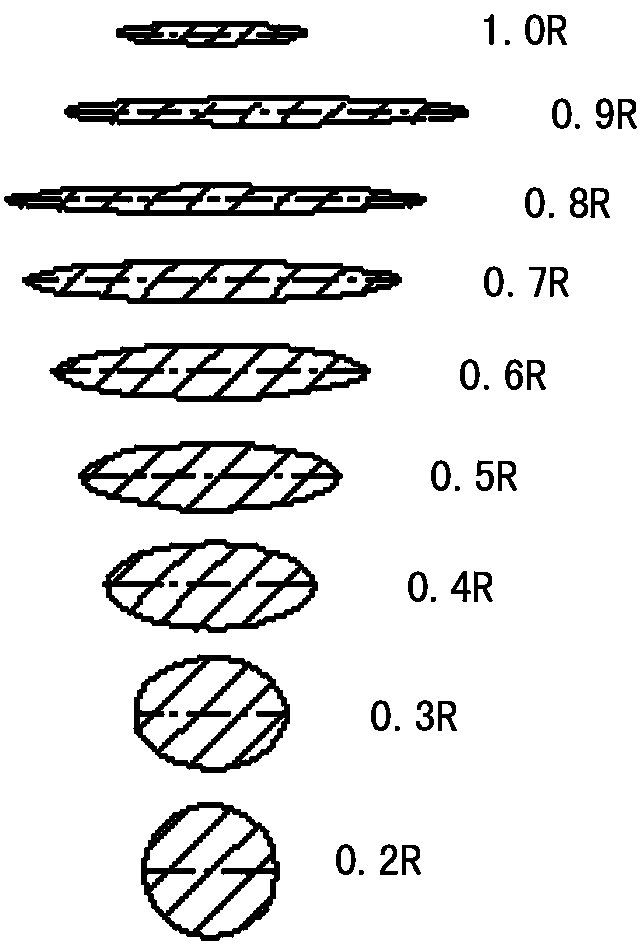

[0017] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , the marine propeller has a propeller hub 1 with a shaft hole in the center, as attached figure 2 , the paddle hub 1 is in the shape of a waist drum, the middle diameter is relatively large, the diameters at both ends are relatively small, and the busbar is streamlined. The paddles 2 are evenly distributed along the circumference of the paddle hub 1, and there are three to six paddles 2 according to the design requirements, and the number of paddles in the embodiment of the drawings is three. The blade surface profile of the paddle 2 is surrounded by a hyperbolic convex leading edge 3, a hyperbolic concave following edge 4 and a circular arc edge 5, and the circular arc edge 5 and the hyperbolic convex leading edge 3 and the hyperbolic concave following edge The connecting points of 4 are W point and S point respectively. The blade surface of blade 2 increases from 0.2 times to 0.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com