Preparation method of graphene macrobody with adjustable pores for supercapacitors

A technology of graphene macroscopic body and supercapacitor, which is applied in the direction of graphene and nano-carbon to achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

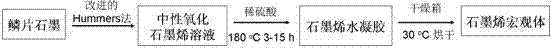

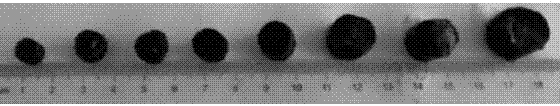

[0013] as per figure 1 The shown procedure prepares graphene macrobodies.

[0014] a. The preparation concentration is 4.5~8.8 mg mL -1 The neutral graphene oxide solution;

[0015] Using flake graphite as raw material, it is prepared according to the Hummers method or according to the following modified Hummers method:

[0016] Mix 3.0 g of graphite flakes with 72 mL of 98% concentrated sulfuric acid, and stir for 5 min in an ice bath; add 1.5 g of potassium nitrate, and continue to stir in an ice bath for 2 h; slowly add 13.5 g of potassium permanganate, and continue to stir for 2 h. The mixture was then transferred to 35 o C water bath for 30 min, then slowly add 189 mL of distilled water, stir well and raise the water bath temperature to 98 o C and continue stirring for 30 min. After the reaction, take out the beaker, slowly add 219 mL of 60 o C of warm water until the total volume of the solution reaches 480 mL, and cool to room temperature. Finally, 4.2 mL of 30% ...

Embodiment 2

[0020] The preparation method is basically the same as in Example 1, except that the concentration of the obtained neutral graphene oxide solution is 4.5 mg mL -1 , adding sulfuric acid at a concentration of 0.01 mol L -1 , and the reaction time was 3 h. The resulting macrobody has a density of 0.9 g cm -3 , with a pore size of about 0.8 nm.

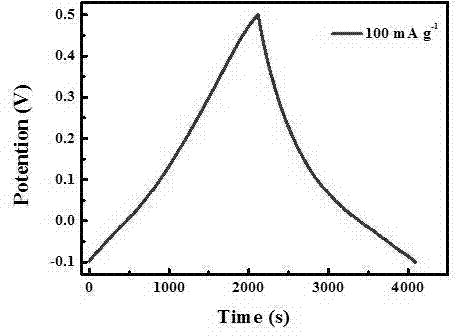

[0021] Electrochemical performance test: The graphene macroscopic body prepared in Example 2 was made into an electrode according to the method in Example 1, and the constant current charge and discharge and cyclic voltammetry tests were carried out. The test result is: at 100 mA g -1 Specific capacitance at current density is 175 F g -1 ; at 10 mV s -1 The specific capacitance at the scan rate is 123 F g -1 .

Embodiment 3

[0023] The preparation method is basically the same as in Example 1, except that the concentration of the neutral graphene oxide solution is 4.5 mg mL -1 , the concentration of sulfuric acid is 0.3 mol L -1 , and the reaction time was 7 h. The resulting macrobody has a density of 0.14 g cm -3 , with a pore size of about 5.2 nm.

[0024] Electrochemical performance test: The prepared graphene macrobody was made into an electrode according to the method in Example 1, and the constant current charge and discharge and cyclic voltammetry tests were carried out. The test result is: at 100 mA g -1 Specific capacitance at current density is 305 F g -1 ; at 10 mV s -1 Specific capacitance at scan rate is 190 F g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com