Process for preparing malolactic fermentation complex flavor distilled white liquor

A preparation process and apple technology, applied in the field of winemaking, can solve the problems of resource shortage, high content of methanol and fusel oil, and achieve the effects of alleviating food shortage, refreshing taste and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand and implement, a kind of preparation technology of apple fermented compound aroma distilled white wine is described in detail below, comprises the following process steps:

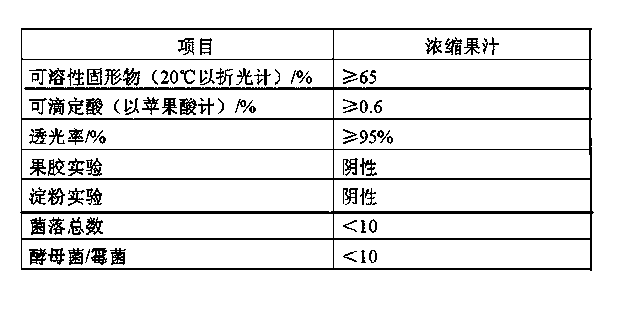

[0016] (1) Pressed apple juice: apples are washed, crushed, squeezed, enzymolyzed, clarified, and made into concentrated apple juice. The titratable acidity of the concentrated apple juice is 0.7%, the sugar content is 70%, and the light transmittance is 96%;

[0017] (2) Fermentation: Dilute the concentrated fruit juice in (1) into fruit juice with a sugar content of 18%, put it into a fermenter, add cerevisiae yeast to ferment at low temperature into apple wine, the fermentation temperature is 18°C, and the fermentation time is 15 days. The alcohol content of the original wine is 8%vol, the total sugar is 198g / L, the volatile acid (calculated as acetic acid) is 1g / L, and the titration acid is 6g / L (calculated as citric acid);

[0018] (3) Sealed storage: Clarify and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com