Heat supply system and heat supply method for soaking pit furnace

A technology of heating system and soaking furnace, which is applied to heat treatment furnaces, furnaces, furnace types, etc., can solve problems such as changes in the flame ejected from the burner and changes in the amount of fuel supplied to the burner, so as to ensure disturbance, strengthen convection and The effect of radiation heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

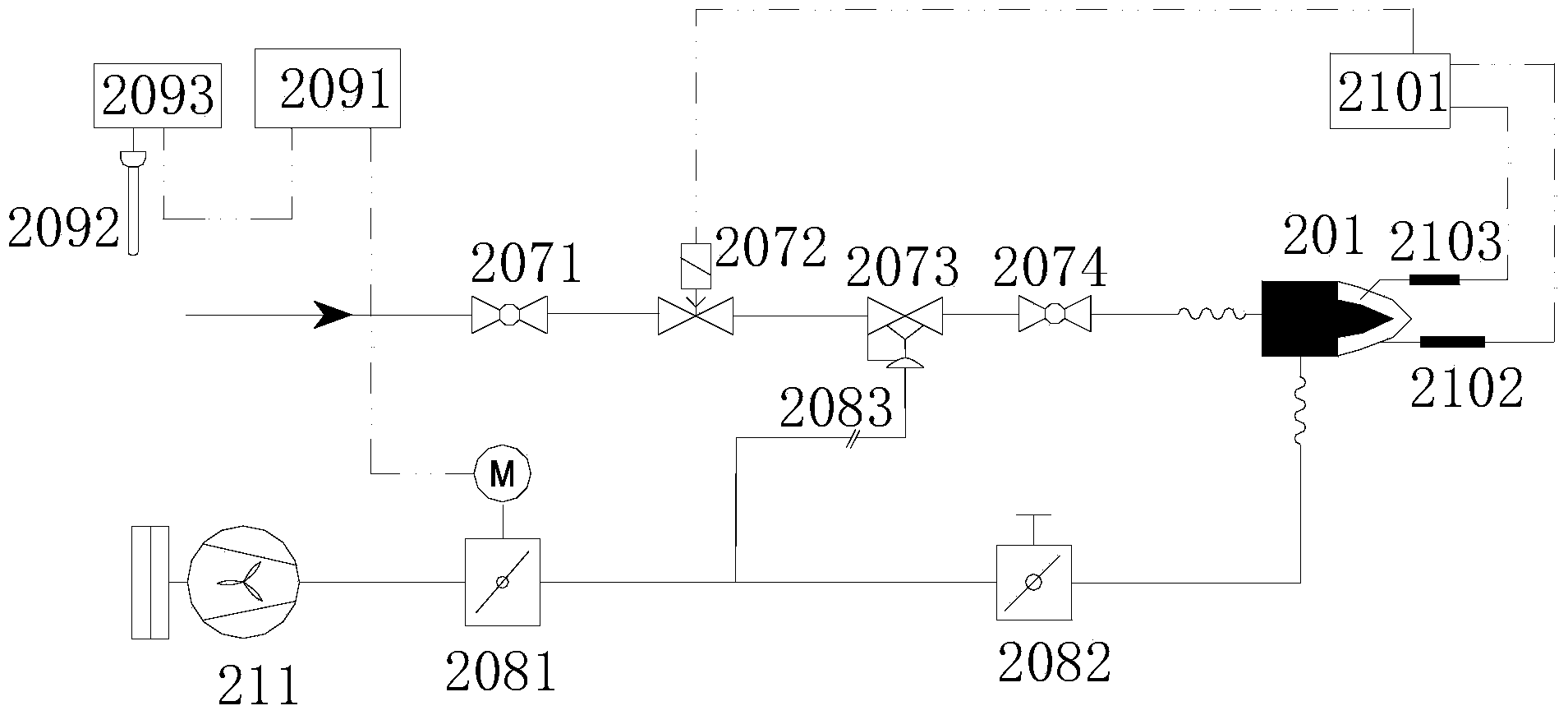

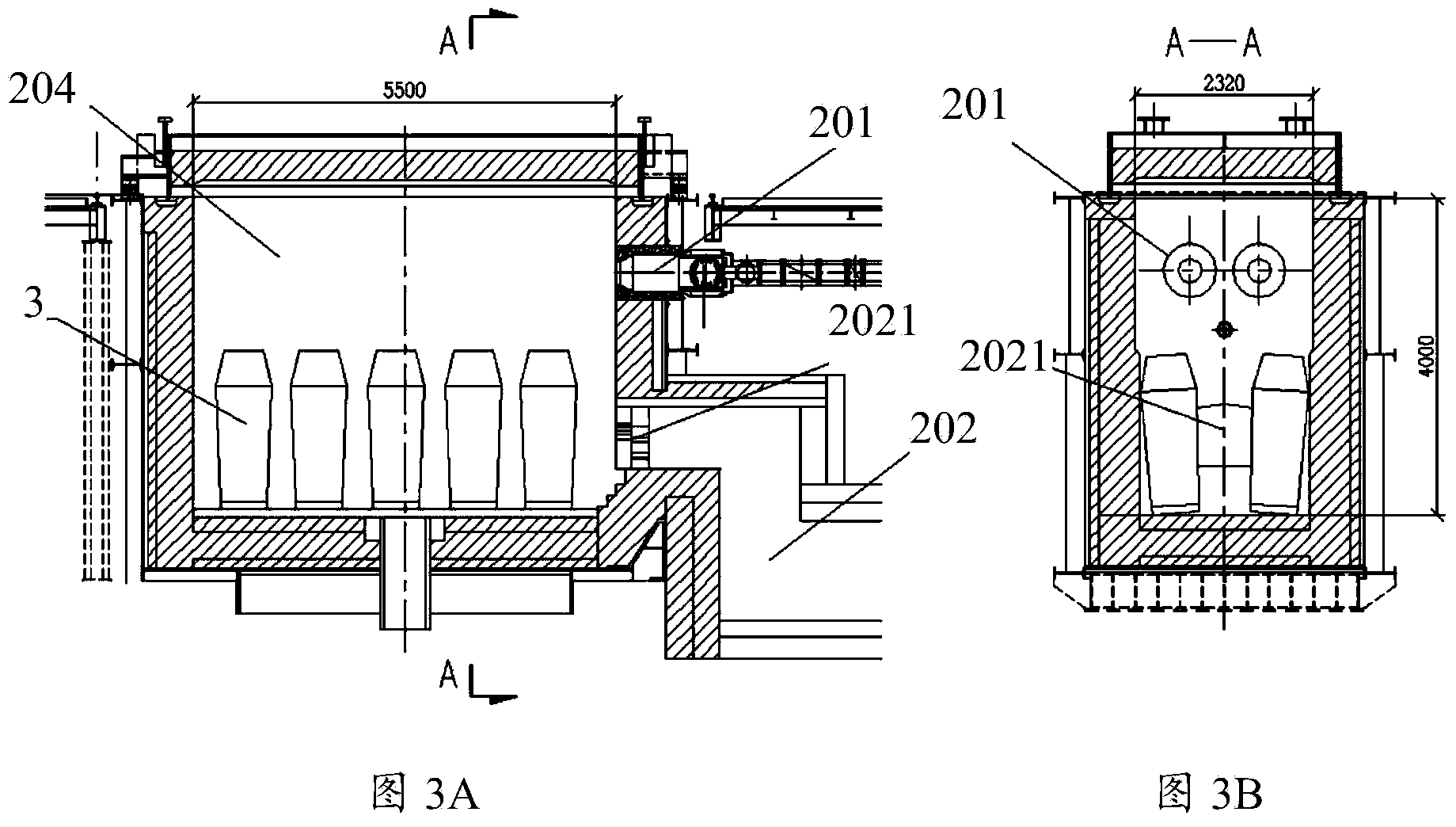

[0030] Such as figure 2 As shown, the soaking furnace heating system according to an embodiment of the present invention includes a high-speed burner 201 and a temperature control system. Among them, each furnace pit of the soaking furnace is provided with at least one high-speed burner 201, before the high-speed burner 201 is connected a gas pipeline for conveying gas and an air pipeline for conveying air, the gas pipeline before the burner and the air before the burner One of the pipelines is provided with a first valve whose opening degree can be adjusted, and the other is provided with a second valve whose opening degree is adjusted according to a predetermined ratio of the opening degree of the first valve. The temperature control system includes a temperature detector 2092 arranged on each pit of the soaking furnace, and a pulse controller 2091 respectively connected to the first valve and the temperature detector 2092 through a circuit. Among them, the pulse controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com