Pretreatment method of deep hole electroplating

A deep hole electroplating and pretreatment technology, applied in the direction of circuits, semiconductor devices, etc., can solve the problems that the air bubbles in the through holes cannot be completely removed, the difference in metal ion concentration, and the concentration of power lines, etc., so as to reduce the amount of residual gas, reduce air bubbles, and increase reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Select the TSV chip with multiple 50×105um deep holes to be plated, select pure water, and cool to 10°C respectively;

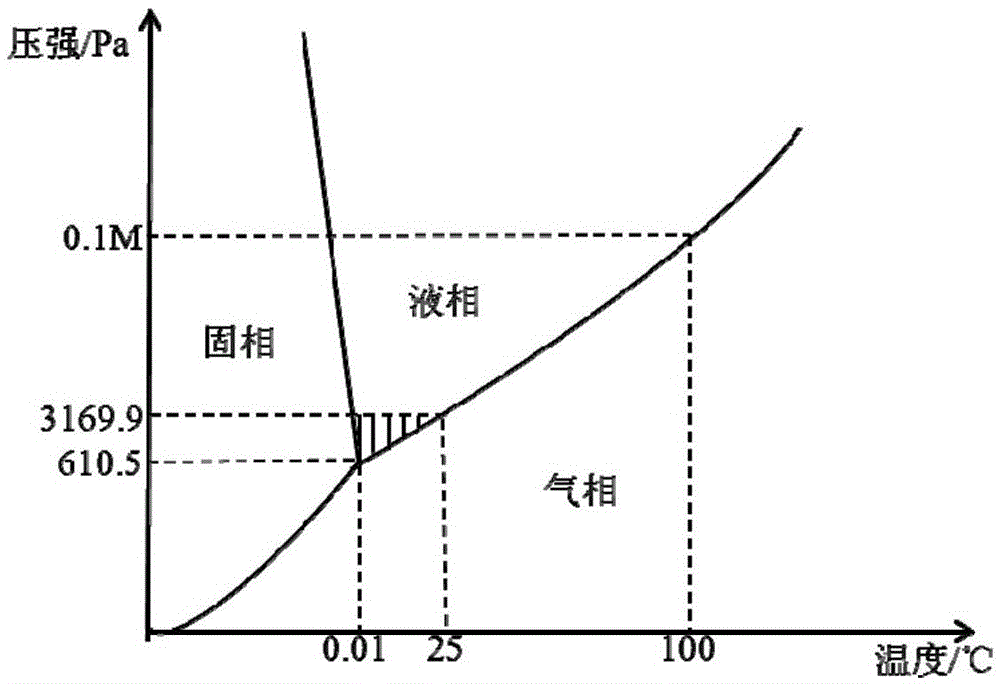

[0029] 2) Vacuumize the TSV chip for 15 minutes, and the vacuum degree is 610.5Pa;

[0030] 3) Soak the TSV chip in the pure water for 10 minutes under vacuum;

[0031] 4) Soak the TSV chip in a plating solution with a copper ion concentration of 40g / L, a hydrogen ion concentration of 10g / L, and a chloride ion concentration of 50ppm, 4ppmSPS, 300ppmPEG, and 100ppmJGB, while stimulating with a small current of 0.5ASD;

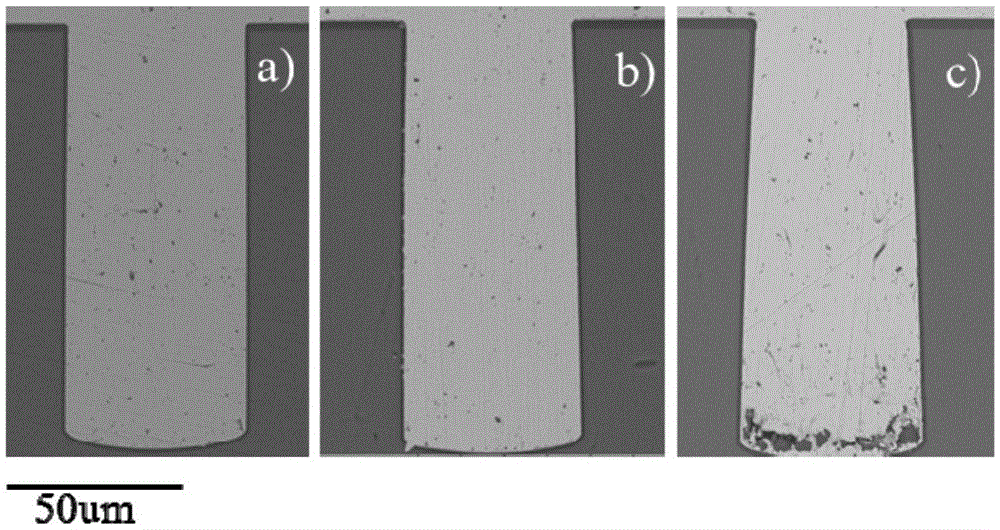

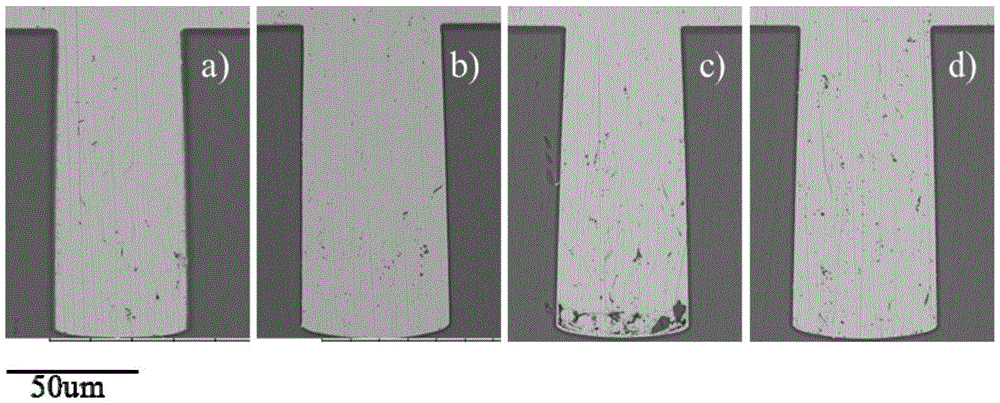

[0032] 5) Electroplating the TSV chip with the above plating solution for 2 hours, with an electroplating current density of 10ASD.

Embodiment 2

[0034] 1) Select 2 pieces of TSV chips with multiple 50×105um deep holes to be plated, select an appropriate amount of pure water, and cool the 2 pieces to 0°C;

[0035] 2) Vacuumize the TSV chips respectively for 10 minutes, and the vacuum degrees are 1000Pa and 2000Pa respectively;

[0036] 3) Soak the TSV chip in the pure water for 2 minutes under vacuum;

[0037] 4) Soak the TSV chip in a plating solution with a copper ion concentration of 40g / L, a hydrogen ion concentration of 10g / L, and a chloride ion concentration of 50ppm, 4ppmSPS, 300ppmPEG, and 100ppmJGB, while stimulating with a small current of 0.01ASD;

[0038] 5) The TSV chip was electroplated for 5 hours using the above plating solution, and the electroplating current density was 0.4ASD.

Embodiment 3

[0040] 1) Select two TSV chips with multiple 50×105um deep holes to be plated, select an appropriate amount of pure water, and cool to 15°C;

[0041] 2) Vacuumize the TSV chips respectively for 10 minutes, and the vacuum degrees are 1000Pa and 2000Pa respectively;

[0042] 3) Soak the TSV chip in the pure water for 2 minutes under vacuum;

[0043] 4) Soak the TSV chip in a plating solution with a copper ion concentration of 40g / L, a hydrogen ion concentration of 10g / L, and a chloride ion concentration of 50ppm, 4ppmSPS, 300ppmPEG, and 100ppmJGB, while stimulating with a small current of 0.01ASD;

[0044] 5) The TSV chip was electroplated for 5 hours using the above plating solution, and the electroplating current density was 0.4ASD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com