A Modular Structure of Radiant Section of Industrial Furnace

A radiant section and modularization technology, which is applied in the field of modular structure of the radiant section of industrial furnaces, can solve the problems of high risk and safety measures, large number of shifts of large machines and tools, and many cross operations on site, so as to reduce on-site The effect of cross operation, reduction of high-altitude operation, and stable construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

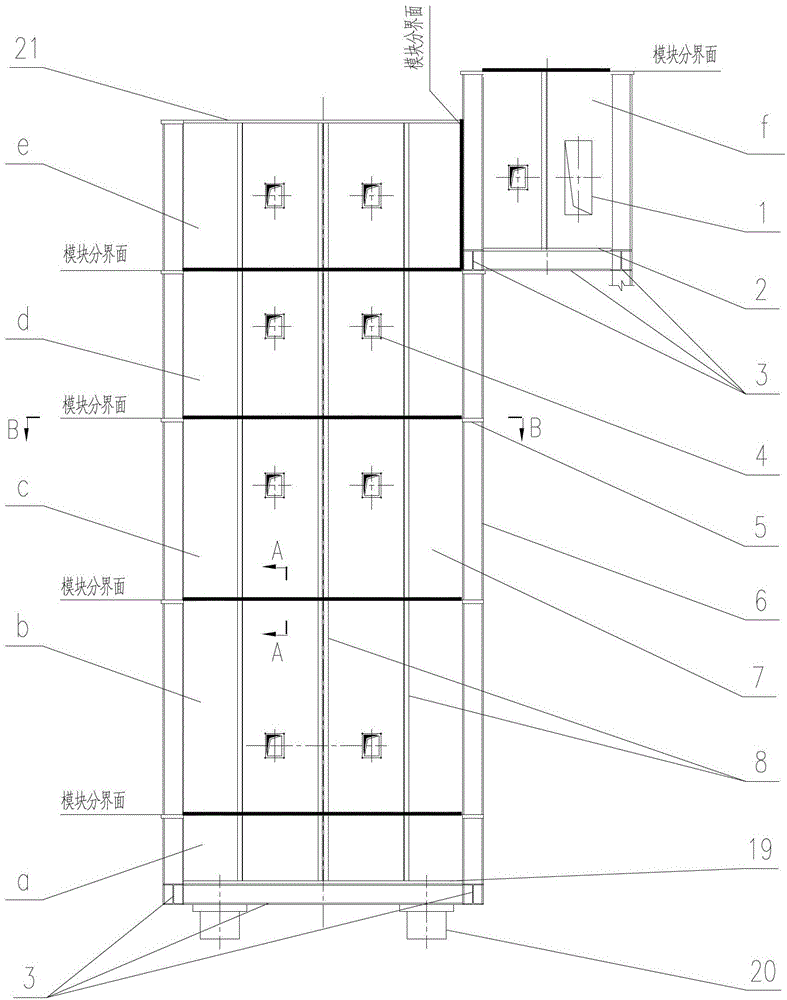

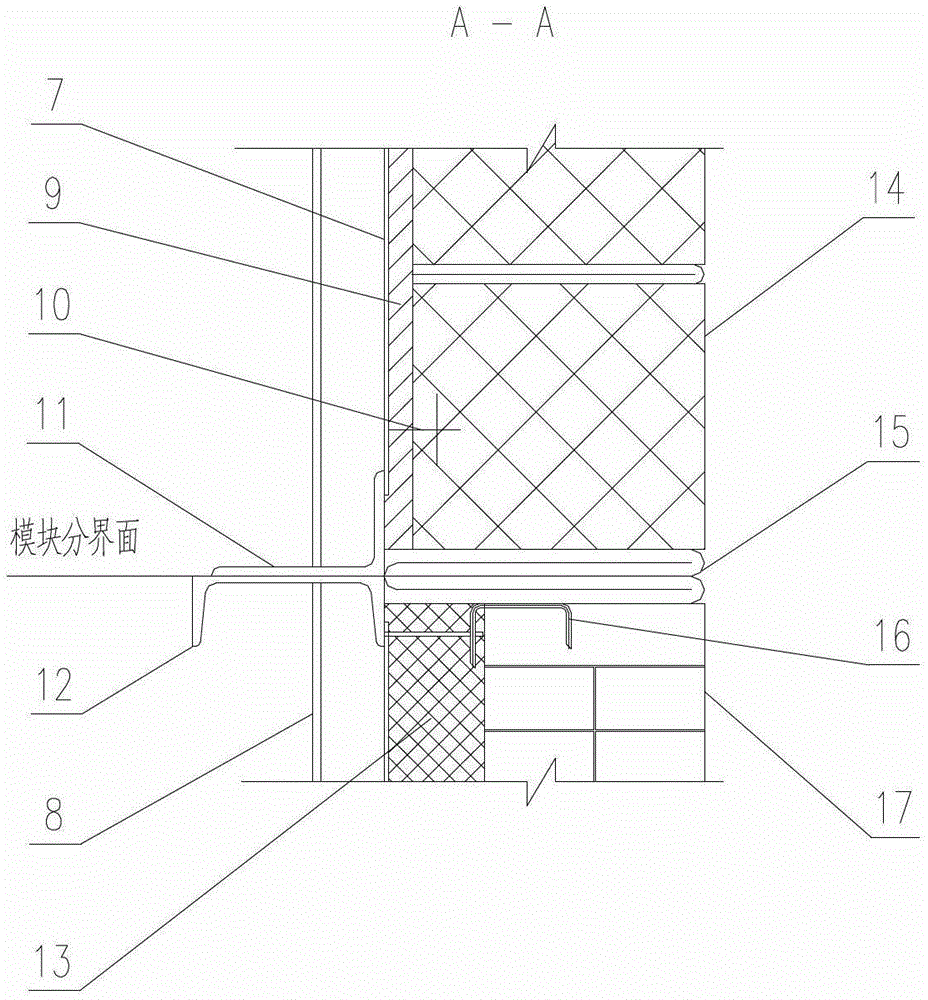

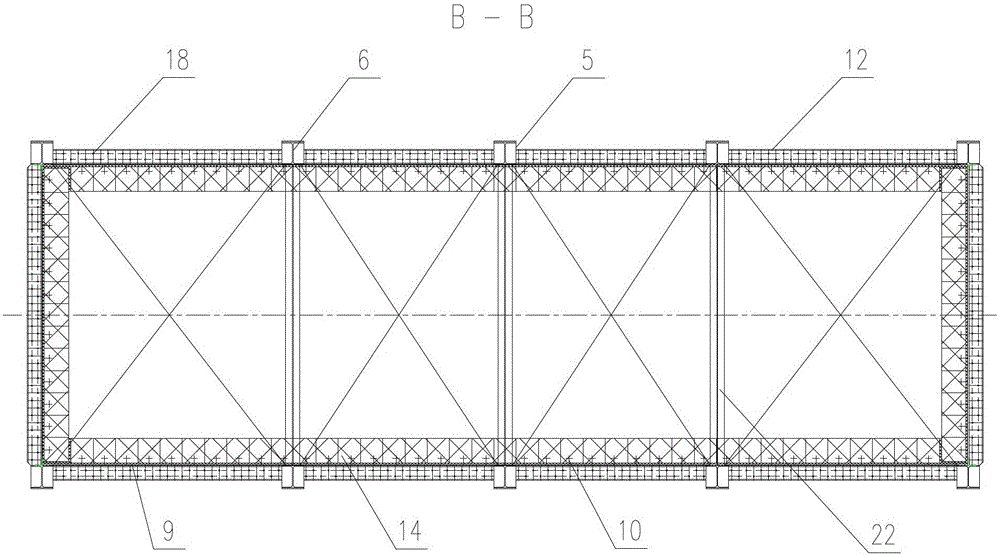

[0046] A modular structure of the radiant section of an industrial furnace, such as figure 1 , figure 2 and image 3 As shown, along the horizontal and vertical directions of the radiation section, the radiation section is divided into six modules: module a, module b, module c, module d, module e, and module f.

[0047] Module a is composed of four facade walls and a furnace bottom 19 of a horizontal radiant section with five surfaces in total. Its steel structure is composed of ten load-bearing columns 6, four load-bearing beams 3, connecting channel steel 12 at the interface of the upper module, furnace wall plate 7 and furnace wall plate reinforced steel 8. The structure of the facade wall and the bottom lining of the horizontal radiant section are: heat-insulating refractory brick backing 13 + heat-insulating refractory brick 17. The heat-insulating refractory brick backing 13 is a ceramic fiber product. The heat-insulating refractory brick anchor nail 16 is welded on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com