Color liquid crystal display panel and manufacturing method thereof

一种液晶显示面板、制作方法的技术,应用在仪器、非线性光学、光学等方向,能够解决不利生产成本的管控、LCD光效率低、制程繁琐等问题,达到提高光穿透率及光效率、降低制造成本、生产制程少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

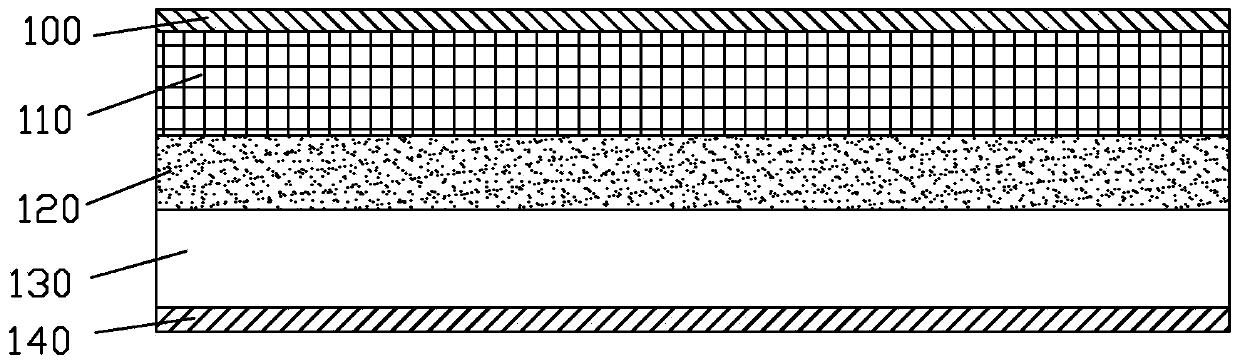

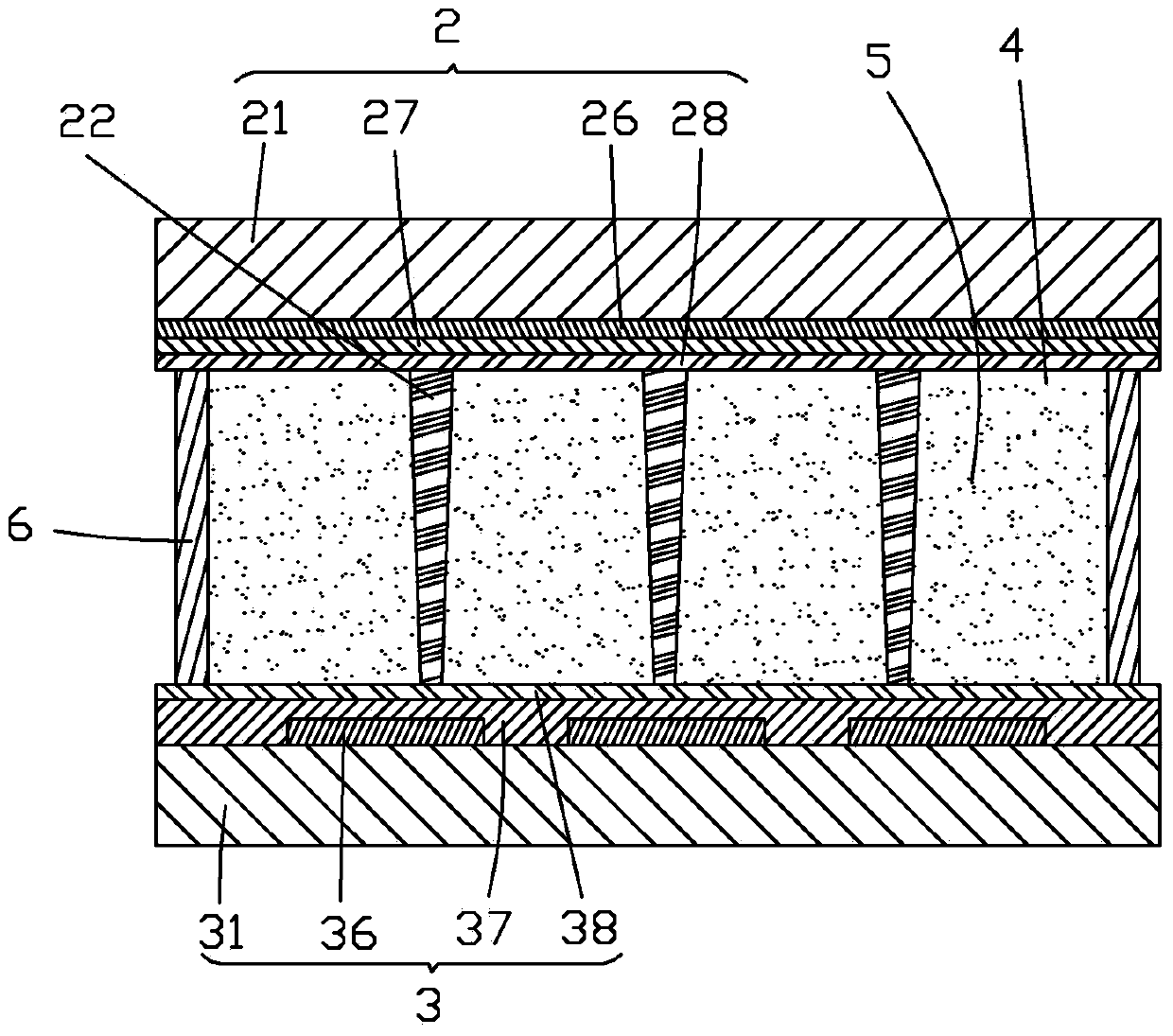

[0038] see Figure 2 to Figure 8 , the present invention provides a color liquid crystal display panel, comprising: a first substrate 2, a second substrate 3 attached to the first substrate 2, and several sub-pixel regions 4 formed on the first substrate 2 , the dye liquid crystal layer 5 disposed in the sub-pixel regions 4 and the sealant frame 6 disposed on the edge of the first substrate 2 and sealing the first and second substrates 2 and 3 together.

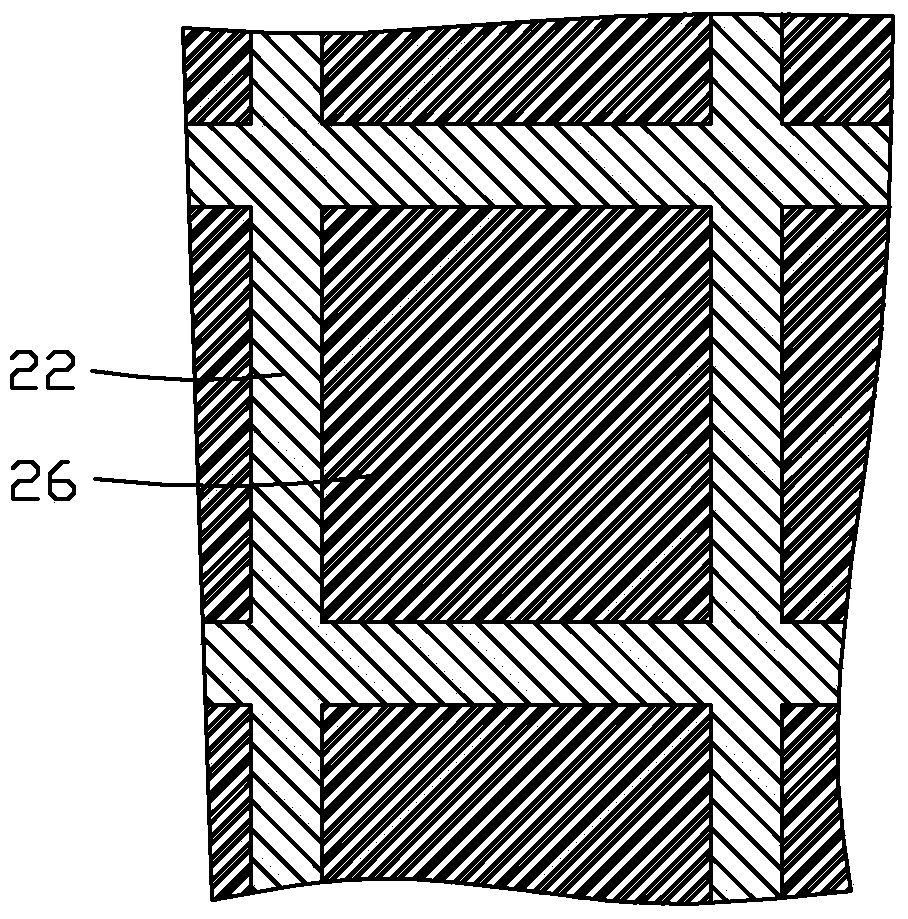

[0039] Such as figure 2 and image 3 As shown, the first substrate 2 is an encapsulation substrate, and the encapsulation substrate includes a first transparent substrate 21, a common electrode 26 formed on the first transparent substrate 21, and a first flat surface formed on the common electrode 26. layer 27, and a first alignment layer 28 formed on the first planarization layer 27.

[0040] The first transparent substrate 21 may be a glass substrate or a plastic substrate, preferably a glass substrate in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com