Method for manufacturing super junction structure

A manufacturing method, N-type technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of not being able to make full use of the chip area, not being able to be used as a current flow path, etc., to reduce the size of the cell, reduce the The effect of simple cost and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments.

[0026] A method for manufacturing a super junction structure is achieved through the following steps:

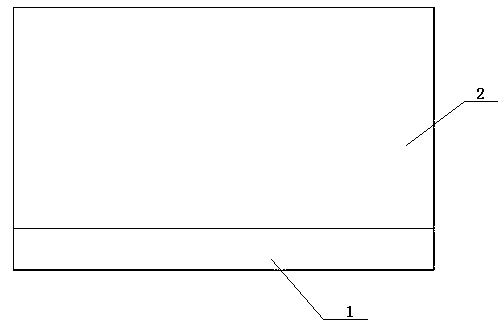

[0027] Step 1: Prepare an N-type heavily doped N+ substrate 1, and form a first N-type epitaxial layer on the N+ substrate 1, using the first N-type epitaxial layer as the N-type drift region 2, see figure 1 ;

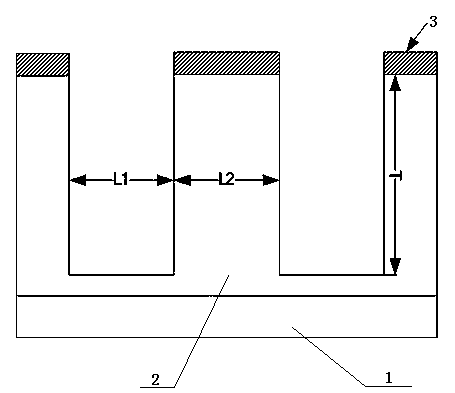

[0028] Step 2: Deposit a protective oxide layer on the upper surface of the N-type drift region 2 and define the trench etched area by photolithography; use an anisotropic etching method to etch the trench on the N-type drift region 2; wherein, The trench depth is T and smaller than the thickness of the N-type drift region 2, the trench width is L1, and the distance between adjacent trenches is L2, see figure 2 ;

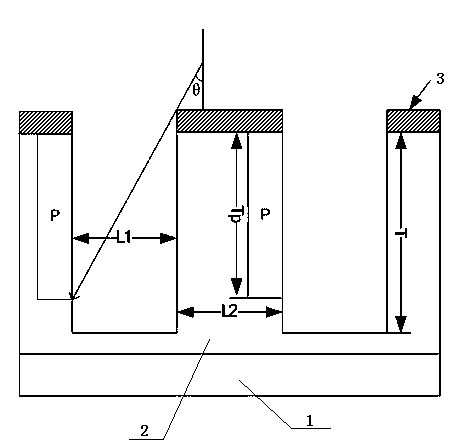

[0029] Step 3: Boron ions are implanted into the two sidewalls of the trench by side injection to form a P column region, the depth of the P column region i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com