Thermocoagulation surgical hemostat

A hemostat and surgery technology, applied in the direction of heating surgical instruments, etc., can solve the problems of affecting the normal operation of other instruments, polluting the environment, increasing costs, etc., and achieve the effects of flexible and convenient handle assembly, no pollution to the environment, and easy cleaning and disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

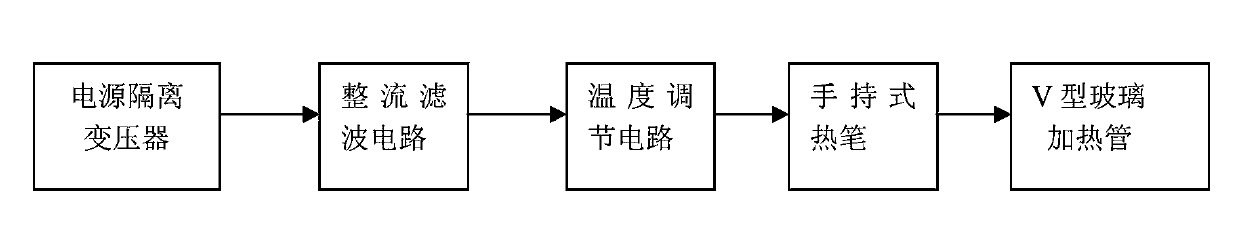

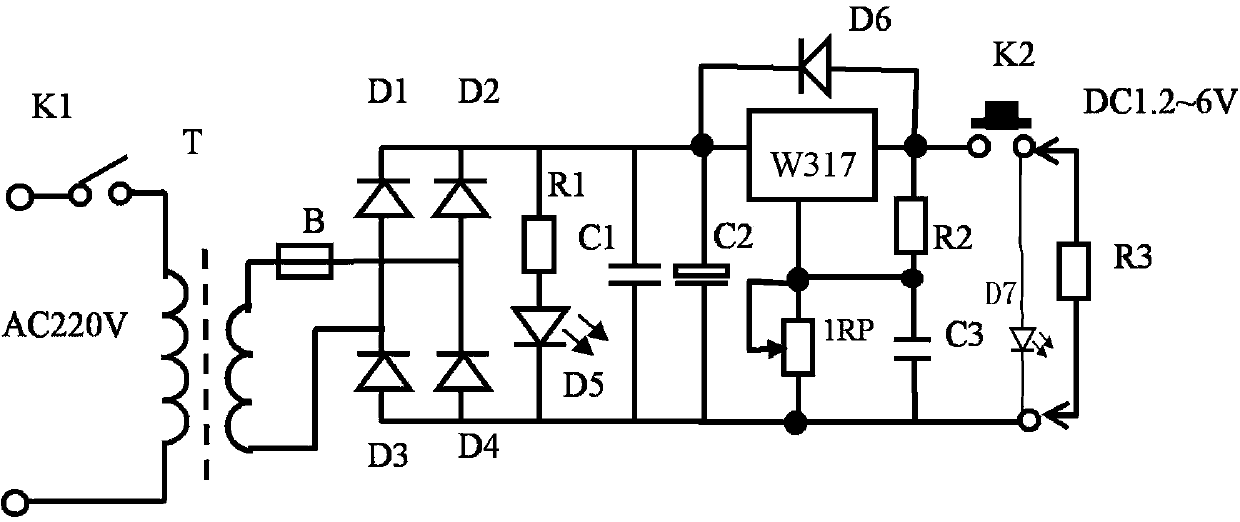

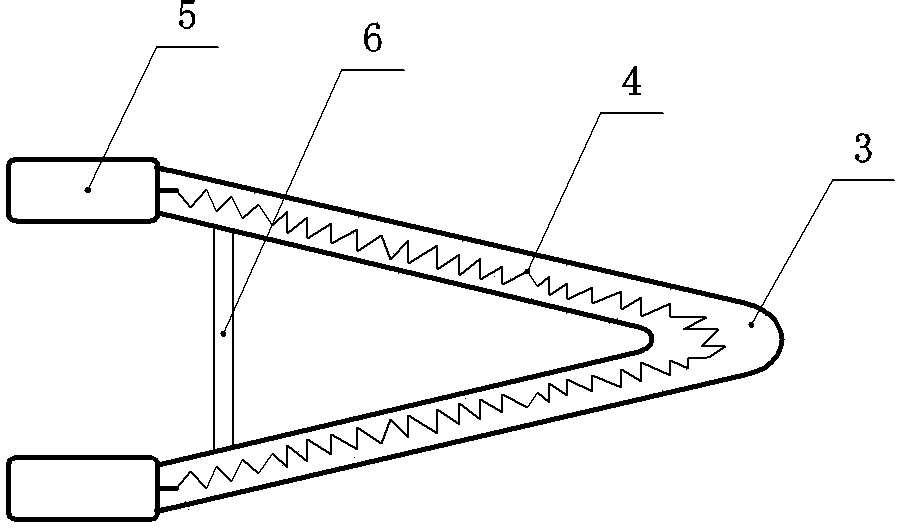

[0025] Such as figure 1 , image 3 , Figure 4 As shown, the present invention proposes a thermocoagulation surgical hemostat, including a heating control circuit, a hand-held thermal pen, the handheld thermal pen includes a handle 1 and a heating body 2, and the heating body 1 is composed of a hollow quartz glass tube 3 Composed of the heating wire 4 arranged therein, the shape of the hollow quartz glass tube is "V" or "U", and the connecting head 5 connected with the heating wire is drawn out from both ends of the hollow quartz glass tube. The front end of the handle 1 is provided with a connecting piece 9 matching the connecting head 5, and the heating wire is connected with the heating control circuit.

[0026] The thermal coagulation operation hemostat of the present invention, the front end working surface of the hollow quartz glass tube is a smooth arc, spherical, inclined or flat surface, and the heating body 2 is matched and connected with the connecting piece 9 at ...

Embodiment 2

[0028] see image 3 The difference between the thermal coagulation surgical hemostat of this embodiment and that of Embodiment 1 is that in order to increase the mechanical strength of the heating body, a reinforcing beam 6 is provided to connect the two branch sections of the "V" or "U" shaped hollow quartz glass tube. .

Embodiment 3

[0030] see Figure 4 The thermal coagulation surgical hemostat of this embodiment is different from Embodiment 1 or Embodiment 2 in that a temperature adjustment or / and heating control switch 7 is set on the handle 1, and the temperature adjustment or / and heating control switch is connected to the The heating control circuit described above.

[0031] A heating wire power-on indicator light 10 may be arranged on the handle for displaying the power-on state of the heating wire. The heating wire indicator light 10 is connected in parallel or in series with the heating wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com