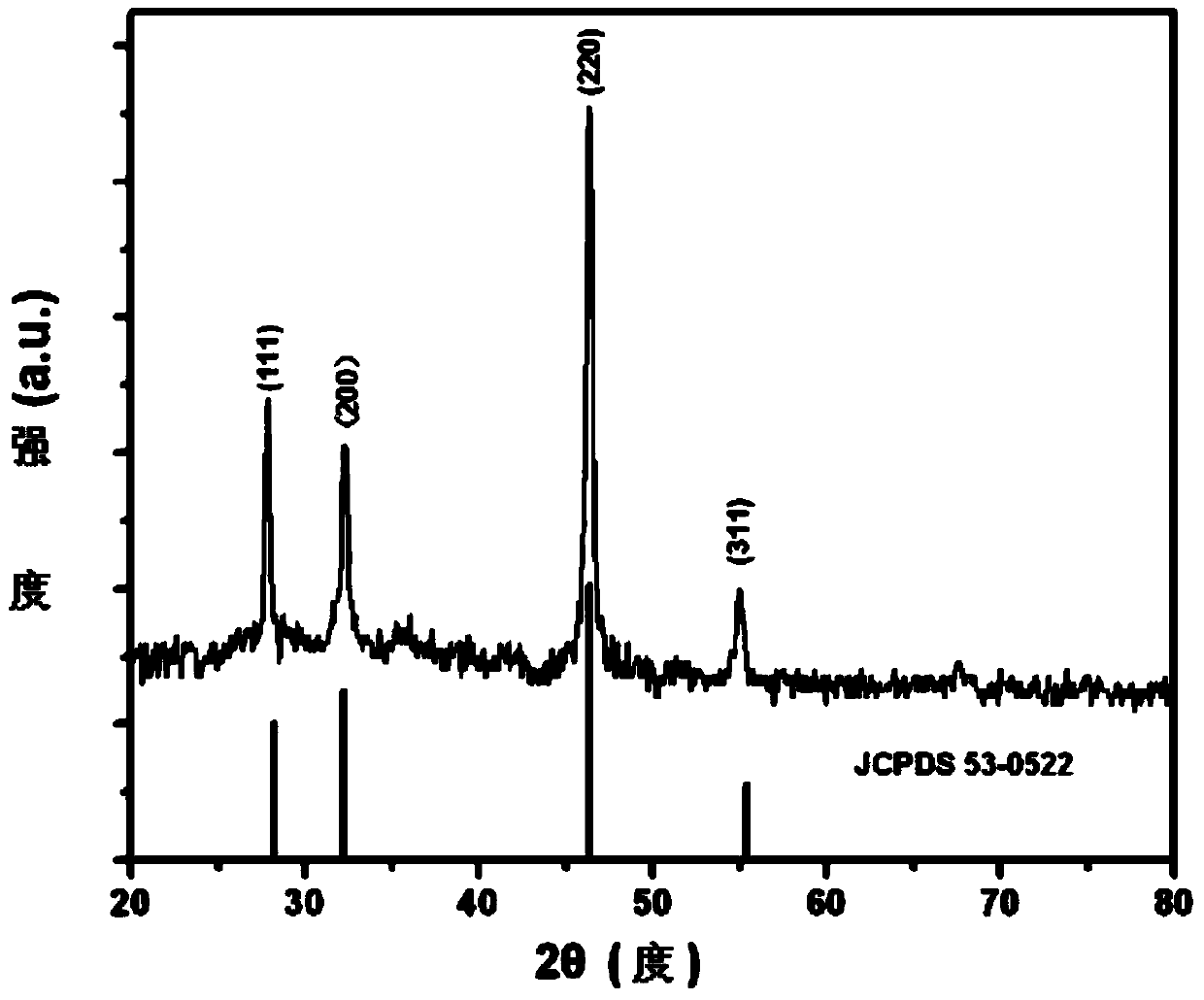

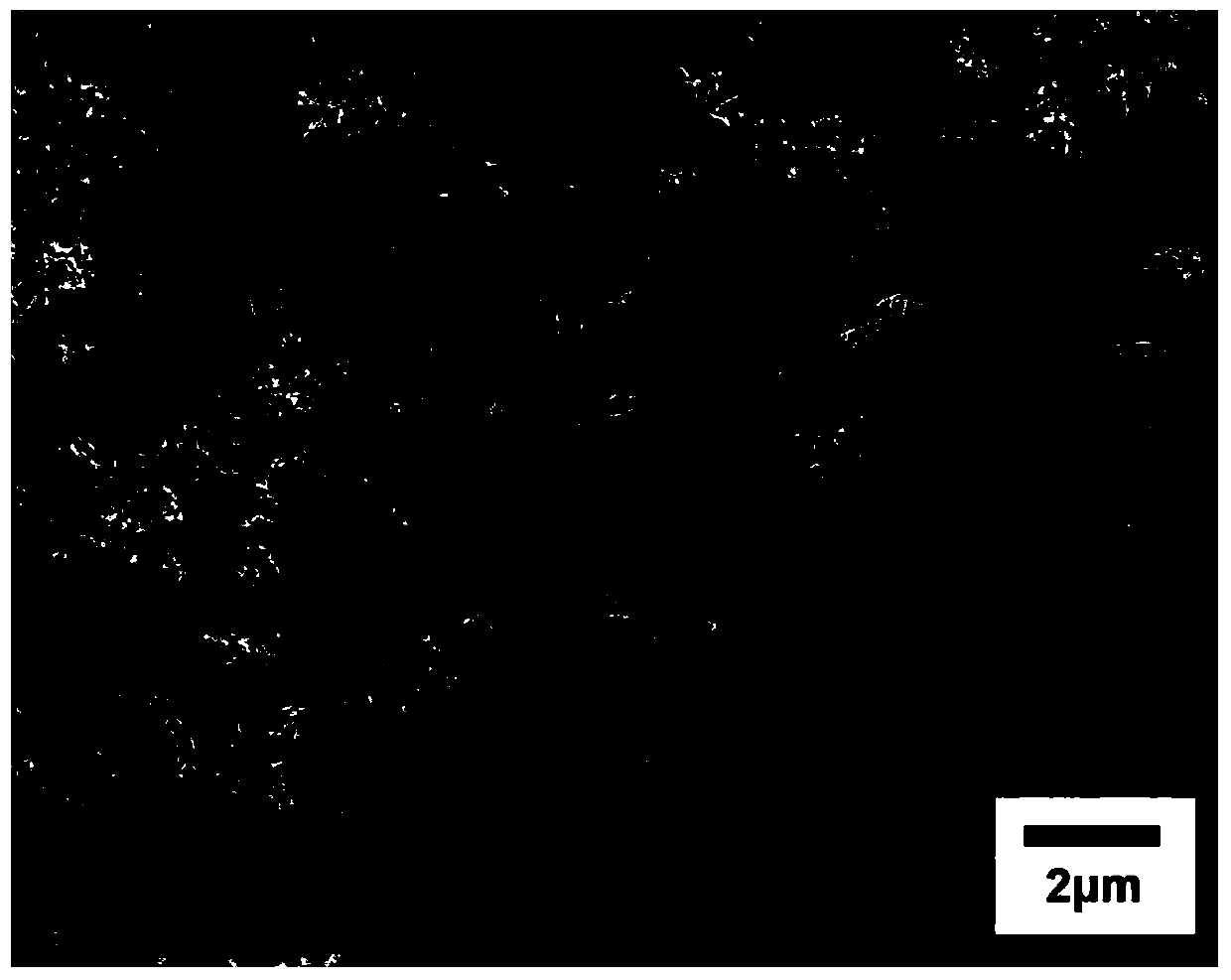

Cuprous sulfide nano ring structure semiconductor material and preparation method thereof

A ring structure, cuprous sulfide technology, applied in the direction of copper sulfide, nanotechnology, nanotechnology, etc., can solve the problems of non-repeatability, limited application, complexity, etc., and achieve low growth temperature, high repeatability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail in conjunction with the following specific embodiments and accompanying drawings. The process, conditions, reagents, experimental methods, etc. for implementing the present invention are general knowledge and common knowledge in the art except for the content specifically mentioned below, and the present invention has no special limitation content.

[0021] The specific preparation steps of cuprous sulfide micron ring semiconductor material in the present embodiment are as follows:

[0022] a. Mix 36ml of absolute alcohol with 4ml of deionized water to make 40ml of a specific solution.

[0023] b. Divide the prepared 40ml solute into two parts and put them into clean beakers respectively.

[0024] c. Put 0.6g CuCl into 20ml solute and mix evenly, put 0.8g thiourea into 20ml solute and mix evenly.

[0025] d. Mix the completely mixed 20ml CuCl solution and 20ml thiourea solution, and stir on a magnetic stirrer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com