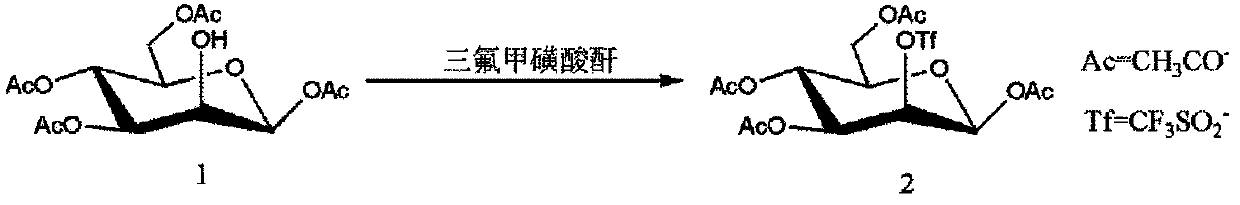

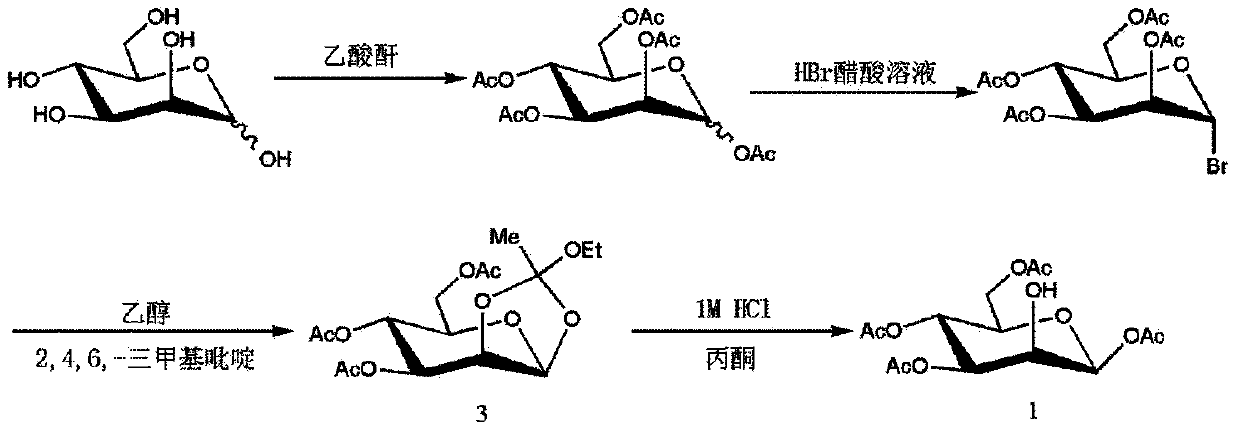

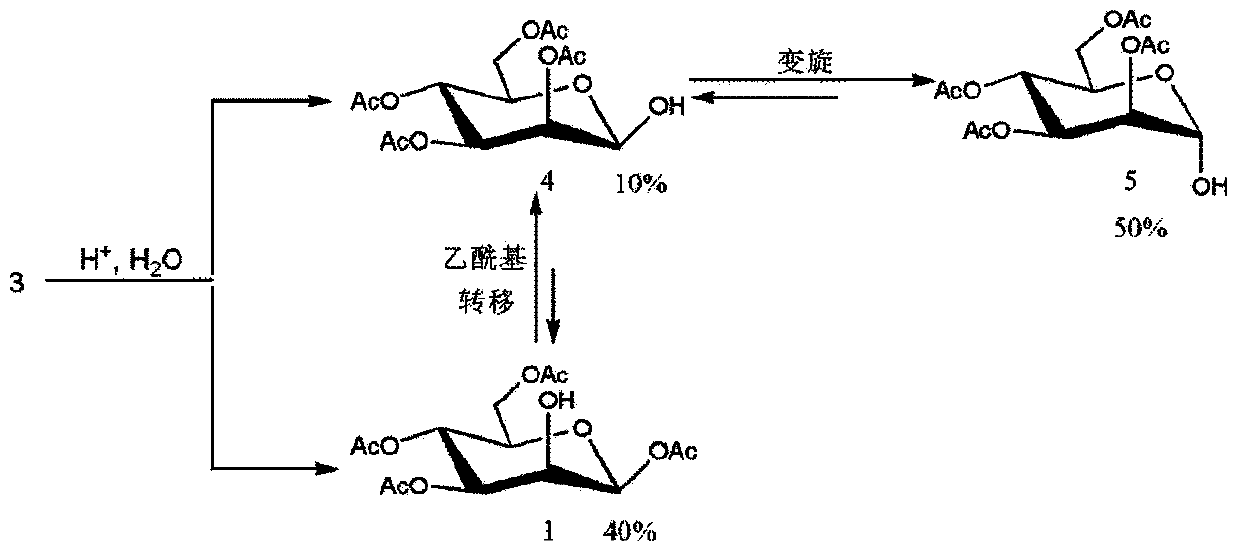

Method for purifying 1,3,4,6-tetra-O-acetyl-2-O-triflat-beta-D-mannopyranose intermediate

A technology of trifluoromannose and purification method, applied in the field of purification of trifluoromannose intermediate, 1,3,4,6-tetraacetyl-β-D-mannose, can solve the problem of yield and purity. High, affecting the yield and purity of trifluoromannose, to achieve the effect of good stability and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The purification method of trifluoromannose intermediate 1,3,4,6-tetraacetyl-β-D-mannose described in this example comprises the following steps:

[0032] Add 50mL of the mixed liquid containing n-butanol and ethylene glycol monomethyl ether in a three-necked flask, the ratio of the volume of n-butanol and ethylene glycol monomethyl ether is 6:1, add the above-mentioned 1,3, 4,6-tetraacetyl-β-D-mannose crude product 10g, and the solution was heated to 80 ° C until the 1,3,4,6-tetraacetyl-β-D-mannose crude product was completely dissolved, then The temperature of the above solution was lowered to 8°C, and allowed to stand for crystallization for 1 hour, and the solution of the above crystallization was filtered, and 3 mL of n-butanol solution was added to wash the above filtered crystals, and the washing was repeated for 2-3 times, and the washed crystals were placed in vacuum at 45°C. After drying for 8 hours, 1,3,4,6-tetraacetyl-β-D-mannose crystals were obtained.

Embodiment 2

[0034] The purification method of trifluoromannose intermediate 1,3,4,6-tetraacetyl-β-D-mannose described in this example comprises the following steps:

[0035] Add 100mL of the mixed liquid containing n-butanol and ethylene glycol monomethyl ether in a three-necked flask, the ratio of the volume of n-butanol and ethylene glycol monomethyl ether is 6:1, add the above-mentioned 1,3, 10 g of crude 4,6-tetraacetyl-β-D-mannose, and heating the solution to 100° C. until the crude 1,3,4,6-tetraacetyl-β-D-mannose is completely dissolved, Subsequently, the above-mentioned dissolving solution was cooled to 10° C., and allowed to stand for crystallization for 2 hours. The above-mentioned crystallization solution was filtered, and 5 mL of n-butanol solution was added to wash the above-mentioned filtered crystals, and the washing was repeated for 2-3 times. °C for 10 hours under vacuum to obtain the 1,3,4,6-tetraacetyl-β-D-mannose crystals.

Embodiment 3

[0037] The purification method of trifluoromannose intermediate 1,3,4,6-tetraacetyl-β-D-mannose described in this example comprises the following steps:

[0038] Add 150mL of the mixed liquid containing n-butanol and ethylene glycol monomethyl ether in a three-necked flask, the volume ratio of n-butanol and ethylene glycol monomethyl ether is 6:1, add the above prepared 1,3, 10 g of crude 4,6-tetraacetyl-β-D-mannose, and heating the solution to 110° C. until the crude 1,3,4,6-tetraacetyl-β-D-mannose is completely dissolved, Subsequently, the above-mentioned solution was cooled to 15° C., and allowed to stand for crystallization for 3 hours, the solution of the above-mentioned crystal was filtered, and 7 mL of n-butanol solution was added to wash the above-mentioned filtered crystal, and the washing was repeated for 2-3 times, and the washed crystal was placed at 55 °C for 12 hours under vacuum to obtain the 1,3,4,6-tetraacetyl-β-D-mannose crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com