Preparation method of near-ultraviolet polystyrene copolymerization fluorescence microsphere

A fluorescent microsphere, polystyrene technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of destroying polymerization conditions, difficult to copolymerize fluorescent microspheres with polystyrene, etc., and achieve high luminous efficiency and good monodispersity. , the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

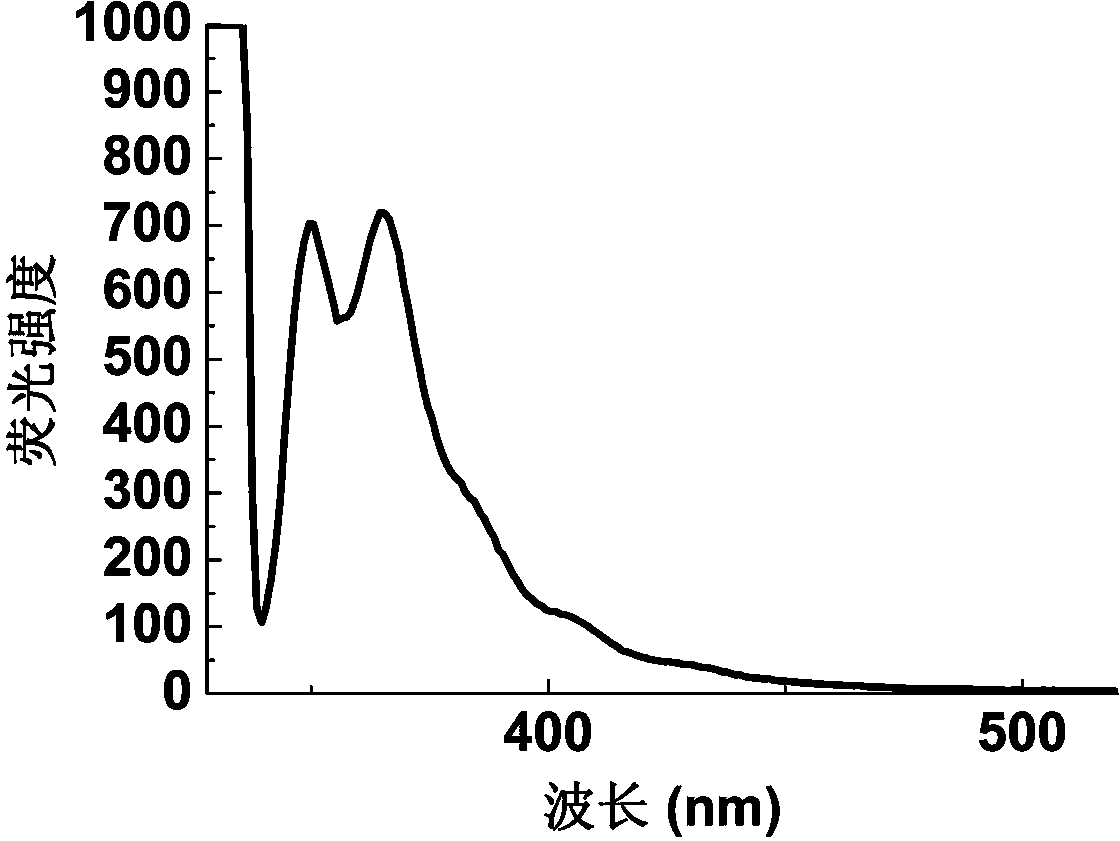

Embodiment 1

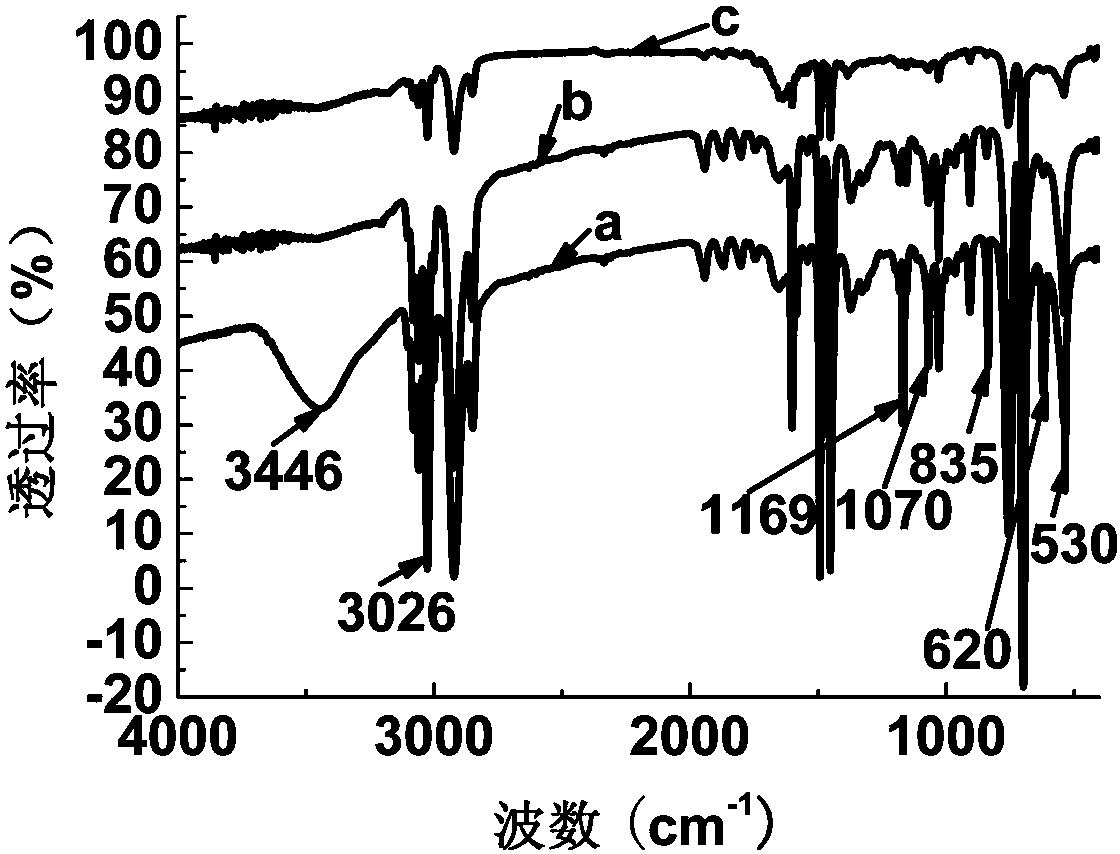

[0025] Take 0.024 g of azobisisobutyronitrile, 0.072 g of polyvinylpyrrolidone, and 9.0 g of absolute ethanol in a microreactor, and ultrasonically obtain a clear and transparent solution. Add 1.2 g of styrene and 7.2 mg of N-allyl carbazole, pass nitrogen to remove oxygen, and seal. Placed in a constant temperature oscillator, reacted at 70°C, 130rpm for 12h. The obtained microspheres were repeatedly washed with water and ethanol until the fluorescence was no longer detected in the washing solution, and then vacuum-dried at 50° C. to obtain polystyrene copolymerized fluorescent microspheres.

[0026] Weigh 1.0 g of the above polystyrene copolymerized fluorescent microspheres, add 28 mL of concentrated sulfuric acid, ultrasonically disperse the fluorescent microspheres in concentrated sulfuric acid, react at 55°C for 7 hours, wash the sample with water until neutral, and dry it in vacuum at 50°C to obtain Sulfonic acid-based functional near-ultraviolet polystyrene copolymeriz...

Embodiment 2

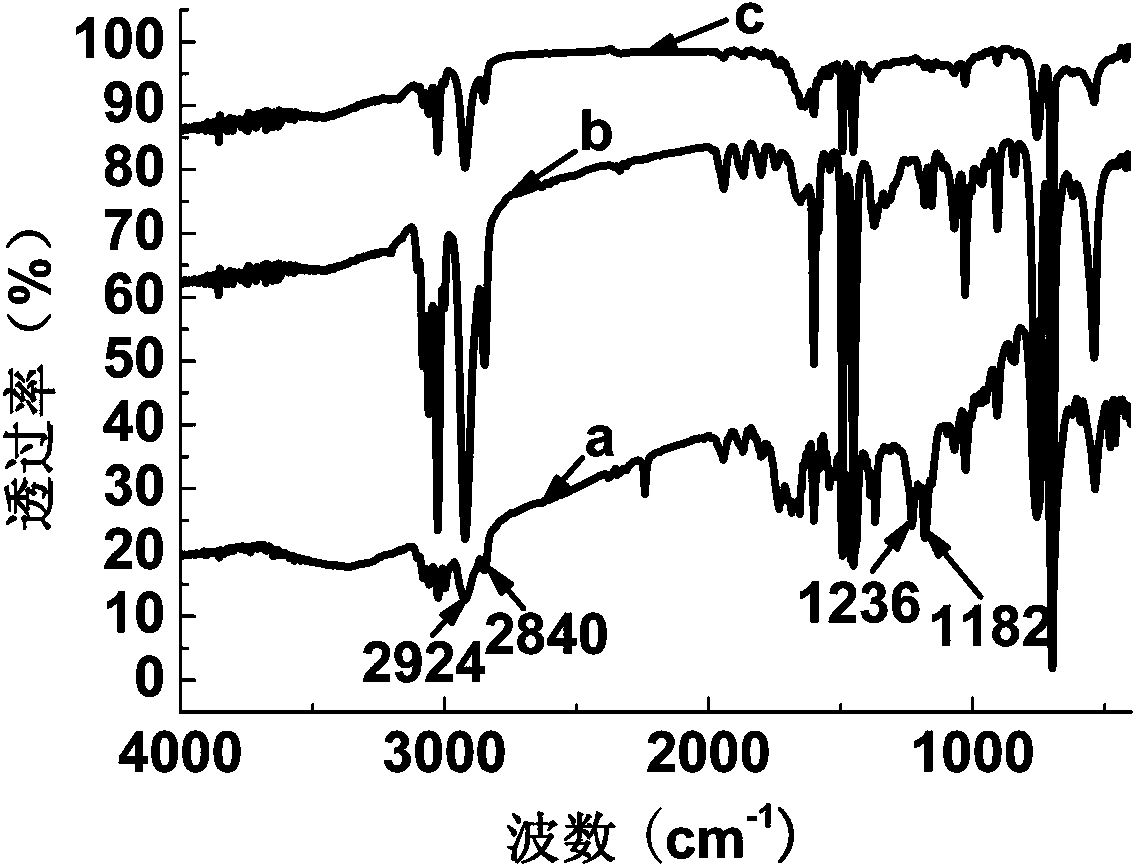

[0028] Take 0.028 g of azobisisobutyronitrile, 0.067 g of polyvinylpyrrolidone, and 9.8 g of absolute ethanol in a microreactor, and ultrasonically obtain a clear and transparent solution. Add 1.4 g of styrene and 11.6 mg of N-allylcarbazole, pass nitrogen to remove oxygen, and seal. Placed in a constant temperature oscillator, reacted at 70°C, 130rpm for 12h. The obtained microspheres were repeatedly washed with water and ethanol until the fluorescence was no longer detected in the washing solution, and then vacuum-dried at 50° C. to obtain polystyrene copolymerized fluorescent microspheres.

[0029] Weigh 0.064g AIBN and disperse in 25.6mL ethanol / deionized water (5:1) mixed solvent. Weigh 0.2 g of the above-mentioned polystyrene copolymerized fluorescent microspheres and add them into the mixed solvent, and ultrasonically disperse them. Nitrogen was passed to remove oxygen, and 0.832 g of γ-methacryloxypropyltrimethoxysilane was added at the same time, sealed and shaken e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com