Preparation method of gardenia yellow pigment

A technology of gardenia yellow pigment and gardenia, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of low impurity content of geniposide, high production cost, poor product quality, etc., and reduce processing Process and concentration times, good product quality, and the effect of improving extraction rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The present invention provides a kind of preparation method of gardenia yellow pigment, wherein, the method comprises the following steps:

[0013] Step 1: Enzymolyze the gardenia raw material for 1-3 times with a compound enzyme preparation to obtain an extract;

[0014] Step 2: Adsorbing and refining the extract with a macroporous adsorption resin to obtain a refined solution, and concentrating the refined solution to obtain a concentrated paste;

[0015] Step 3: crystallize the concentrated paste with a crystallization solvent to obtain a gardenia yellow pigment product.

[0016] Wherein, the gardenia raw material is the raw material granules obtained by crushing the fruit of Gardenia jasminoides Ellis (Gardenia jasminoides Ellis), a Rubiaceae plant, and passing through a 10-mesh sieve.

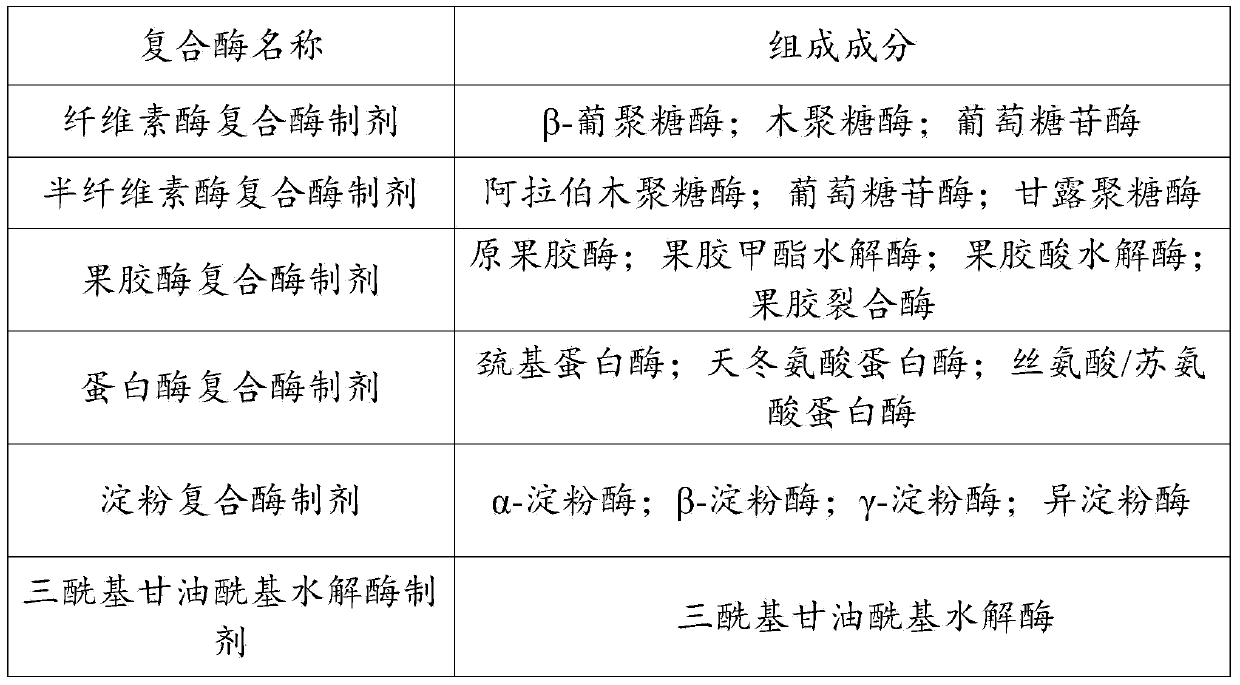

[0017] In the method provided by the present invention, the compound enzyme preparation is selected from one or more of the group consisting of cellulase, hemicellulase, pectinase,...

Embodiment 1

[0053] According to the ratio listed in Table 2, add pure water and compound enzyme preparation to 1000g gardenia raw material to obtain the extraction system, adjust the pH value of the system to 4.6 with acetic acid-sodium acetate, and at the extraction temperature of 37 ° C, at 300 rpm Extract at a stirring speed of 1.3 h for 1.3 hours, filter the extract with a 400-mesh sieve and then extract twice under the same extraction conditions, combine the three extracts and filter with medium-speed filter paper to obtain a total extract of 8500g, and extract the extract at a medium-speed filter paper, filtrate collection; extract 2.43; use LSA-10 macroporous adsorption resin 500mL to refine the extract: adsorption: adsorption capacity 8.5BV, adsorption flow rate 1BV / h, direction up and down. Water washing: water consumption 10BV, flow rate 1BV / h, direction up and down. Desorption: 60 volume% ethanol desorption, the dosage is 1BV, the flow rate is 0.5BV / h, and the direction is up...

Embodiment 2

[0056] According to the ratio listed in Table 2, add pure water and compound enzyme preparation to 1000g gardenia raw material to obtain the extraction system, adjust the pH value of the system to 4.8 with acetic acid-sodium acetate, and at the extraction temperature of 35 ° C, at 300 rpm Extract at a stirring speed of 1.2 h for 1.2 hours, filter the extract with a 400-mesh sieve and then extract twice under the same extraction conditions, combine the three extractions with medium-speed filter paper and filter to obtain a total extract of 8535g, and pass the extract through medium-speed filter paper , the filtrate is collected; the extract 2.30; use LSA-20 macroporous adsorption resin 500mL to refine the extract: Adsorption: The adsorption capacity is 8.84BV, the adsorption flow rate is 1BV / h, and the direction is up and down. Water washing: water consumption 10BV, flow rate 1BV / h, direction up and down. Desorption: desorption with 60% ethanol by volume, the dosage is 1BV, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com