Method for preparing jatropha curcas seed fat by microbiological fermentation process

A microbial fermentation method, a technology for Jatropha curcas seeds, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of poor comprehensive utilization, low preparation efficiency, and low extraction rate of Jatropha curcas seeds , to achieve the effect of fast breeding of bacteria, improving utilization rate and improving feed protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

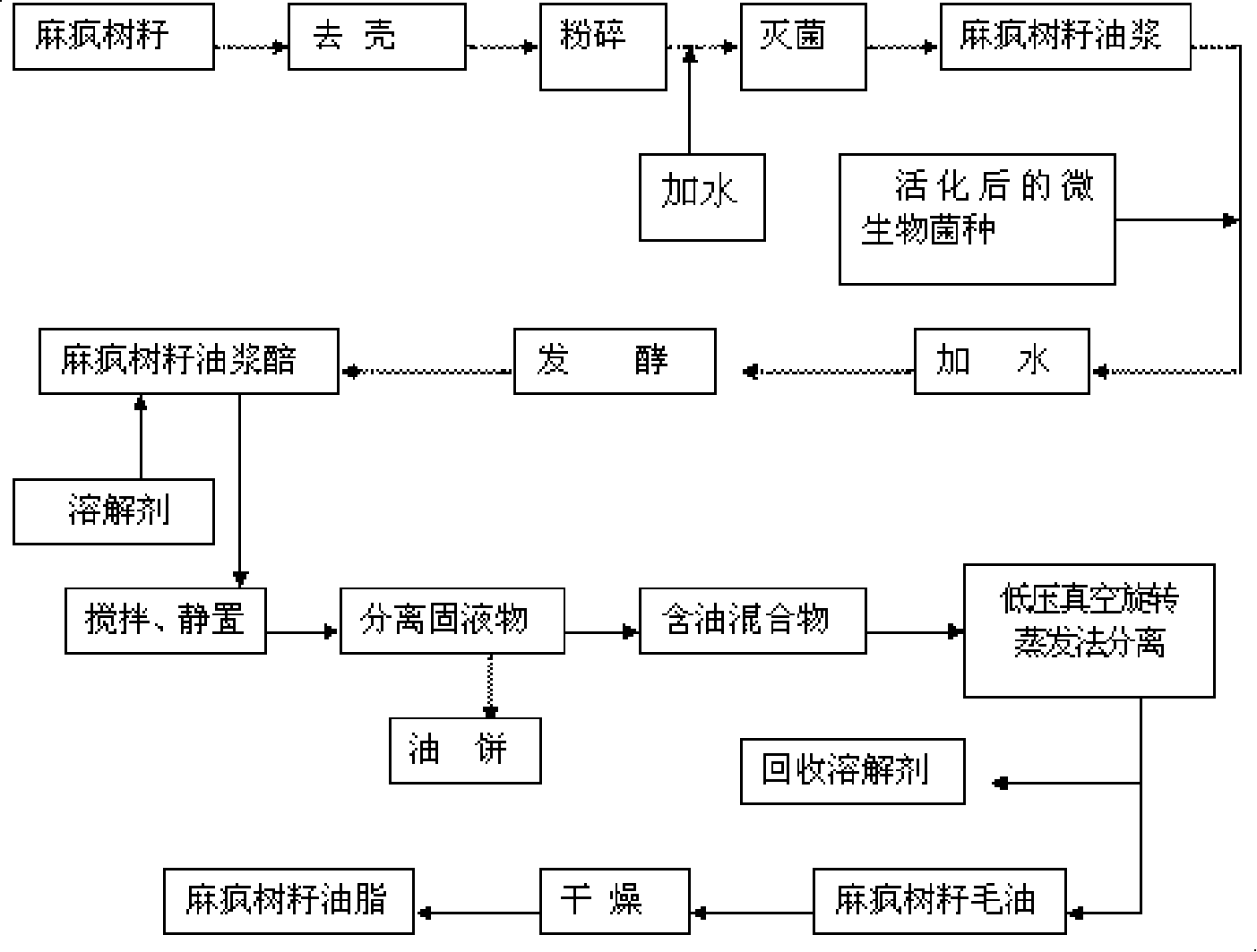

[0027] Embodiment 1: as figure 1 shown

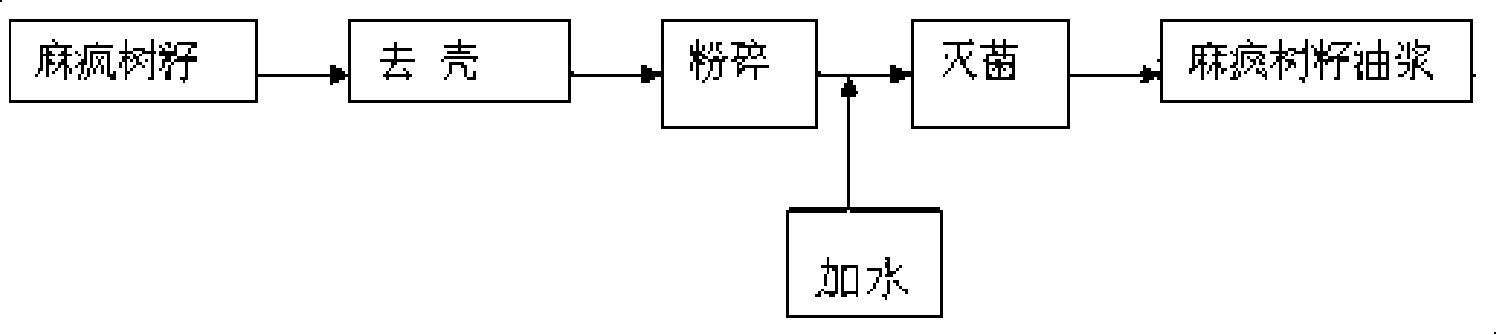

[0028] Step 1, to the pretreatment of Jatropha curcas seed, see figure 2 ,

[0029] Shell the 100kg jatropha seeds that remove impurities such as moldy particles and soil by screening; use a pulverizer or grind and pulverize, and the particles of the jatropha seeds after the pulverization are 30 to 50 meshes to obtain jatropha seed oil slurry , and then add hot water to the jatropha seed oil slurry to adjust, so that the water content in the jatropha seed reaches 40%, and heat to 100° C. for sterilization.

[0030] Step 2, the fermentation process to Jatropha seed oil slurry

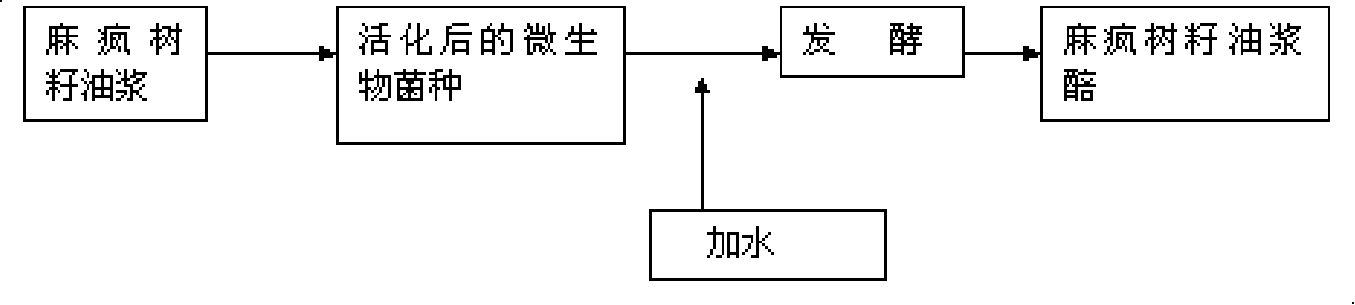

[0031] see image 3 , add 19.8kg of sterilized water containing 2% sugar to 0.2kg of Angel Yeast, and mix it at a temperature of 30°C, place it for 20 minutes to obtain activated microbial bacteria, and mix the activated microbial bacteria into the step 1. Add water to the obtained product to make the moisture content reach 50%, stir evenly, stir and ferment...

Embodiment 2

[0034] Embodiment 2: as figure 1 shown

[0035] Step 1, to the pretreatment of Jatropha curcas seed, see figure 2 ,

[0036] Shell the 100kg jatropha seeds that remove impurities such as moldy particles and soil by screening; use a pulverizer or grind and pulverize, and the particles of the jatropha seeds after the pulverization are 30 to 50 meshes to obtain jatropha seed oil slurry , and then add hot water to the jatropha seed oil slurry to adjust, so that the water content in the jatropha seed reaches 70%, and heat to 100° C. for sterilization.

[0037] Step 2, the fermentation process to Jatropha seed oil slurry

[0038] see image 3 , add 24.5kg of Gao's culture medium to 0.5kg of Geotrichum candidum (also can use Aspergillus oryzae, Rhizopus chinensis or mold MJ18), and mix at a temperature of 35°C, place in a 28-30°C incubator to activate 24- After 48 hours to obtain microbial bacteria, mix the activated microbial bacteria into the product obtained in step 1, and a...

Embodiment 3

[0041] Embodiment 3: as figure 1 shown

[0042] Step 1, to the pretreatment of Jatropha curcas seed, see figure 2 ,

[0043] Shell the 100kg jatropha seeds that remove impurities such as moldy particles and soil by screening; use a pulverizer or grind and pulverize, and the particles of the jatropha seeds after the pulverization are 30 to 50 meshes to obtain jatropha seed oil slurry , and then add hot water to the jatropha seed oil slurry to adjust, so that the water content in the jatropha seed reaches 55%, and heat to 100° C. for sterilization.

[0044] Step 2, the fermentation process to Jatropha seed oil slurry

[0045] see image 3, Add 22kg of Gao's culture medium to 0.3kg of Geotrichum candidum, Aspergillus oryzae, Rhizopus chinensis and mold MJ18, and mix them at a temperature of 33°C, place in a 28-30°C incubator to activate for 24-48 hours After obtaining the microbial bacteria, mix the activated microbial bacteria into the product obtained in step 1, and add w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com