Preparation method of high-specific-surface porous TiO2 nano-fiber

A nanofiber, high specific surface technology, applied in the field of photocatalytic materials, can solve the problems of complex process and high preparation cost, and achieve the effects of high photocatalytic stability and chemical stability, and high photocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

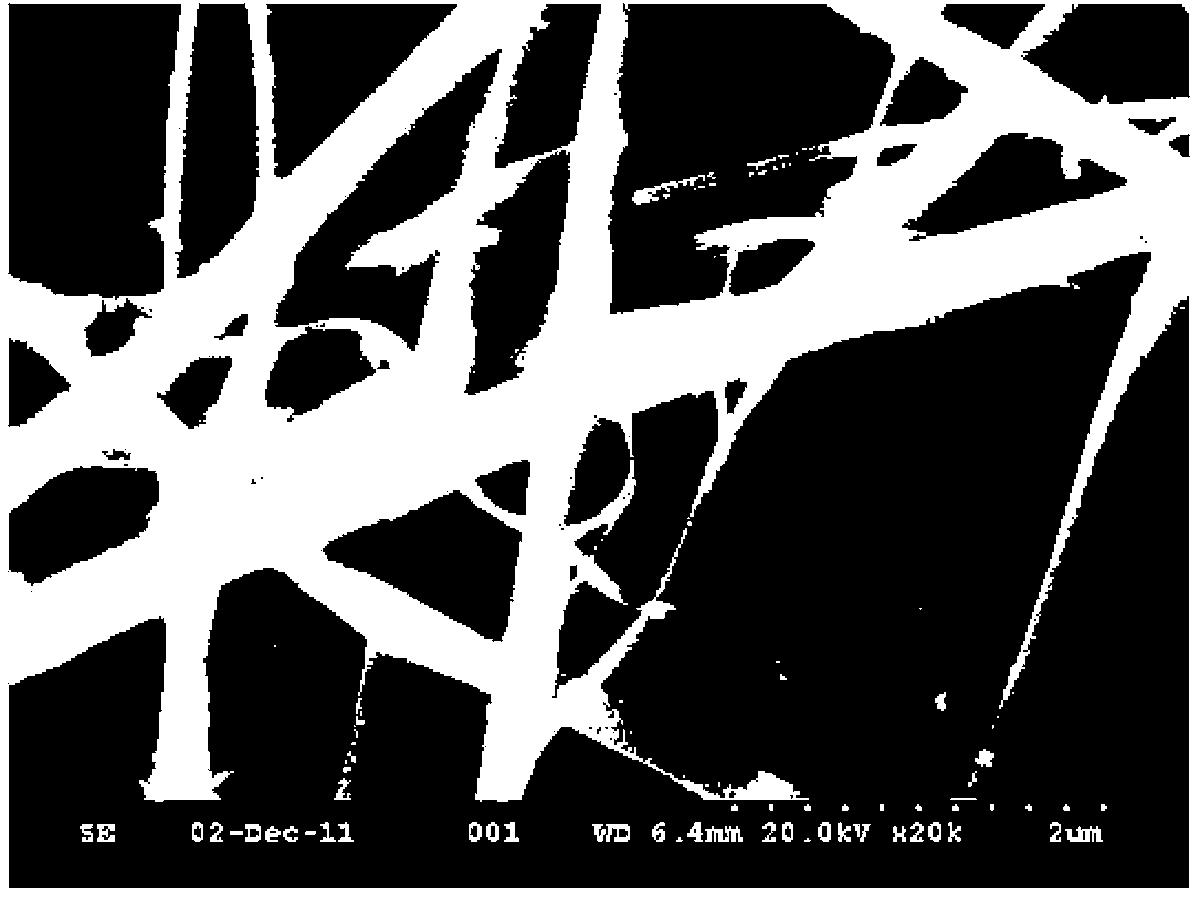

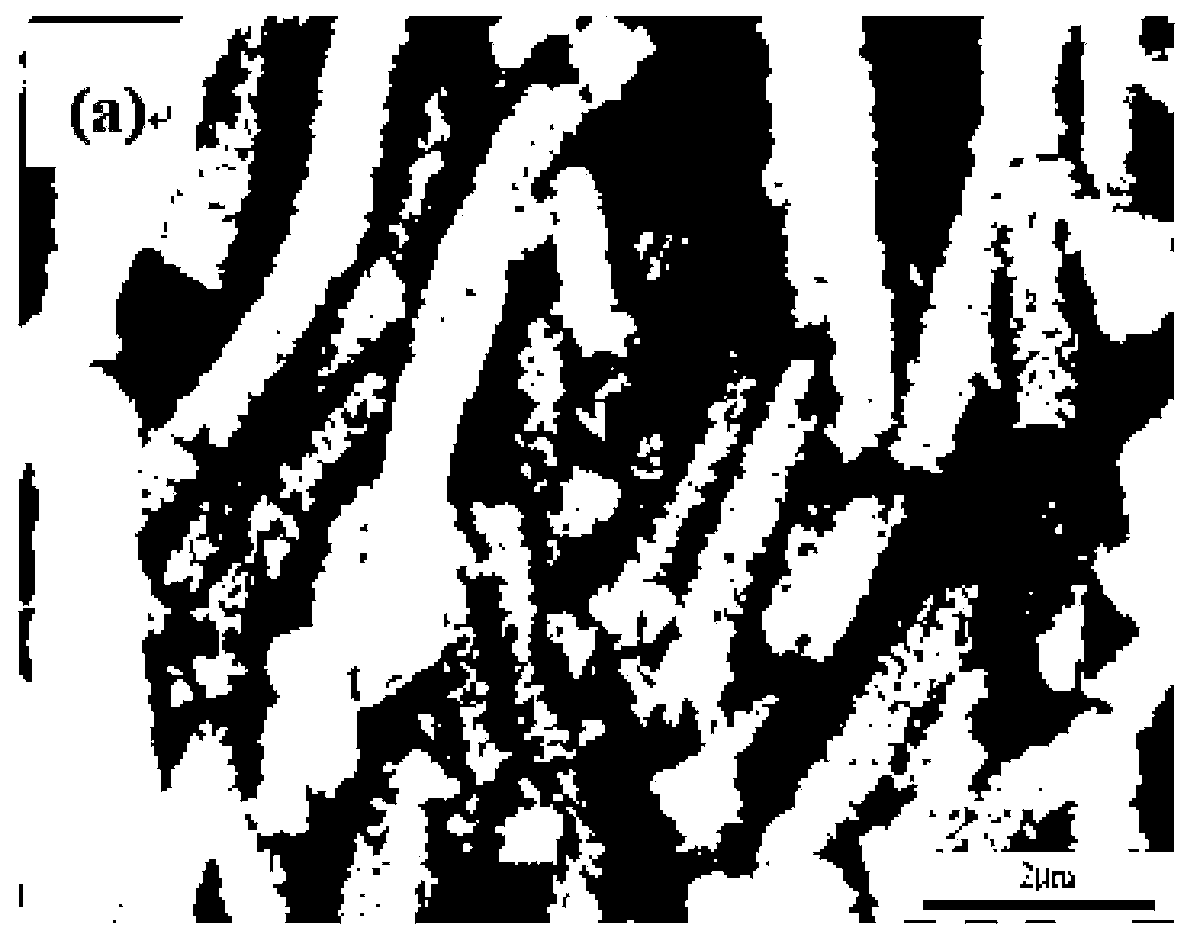

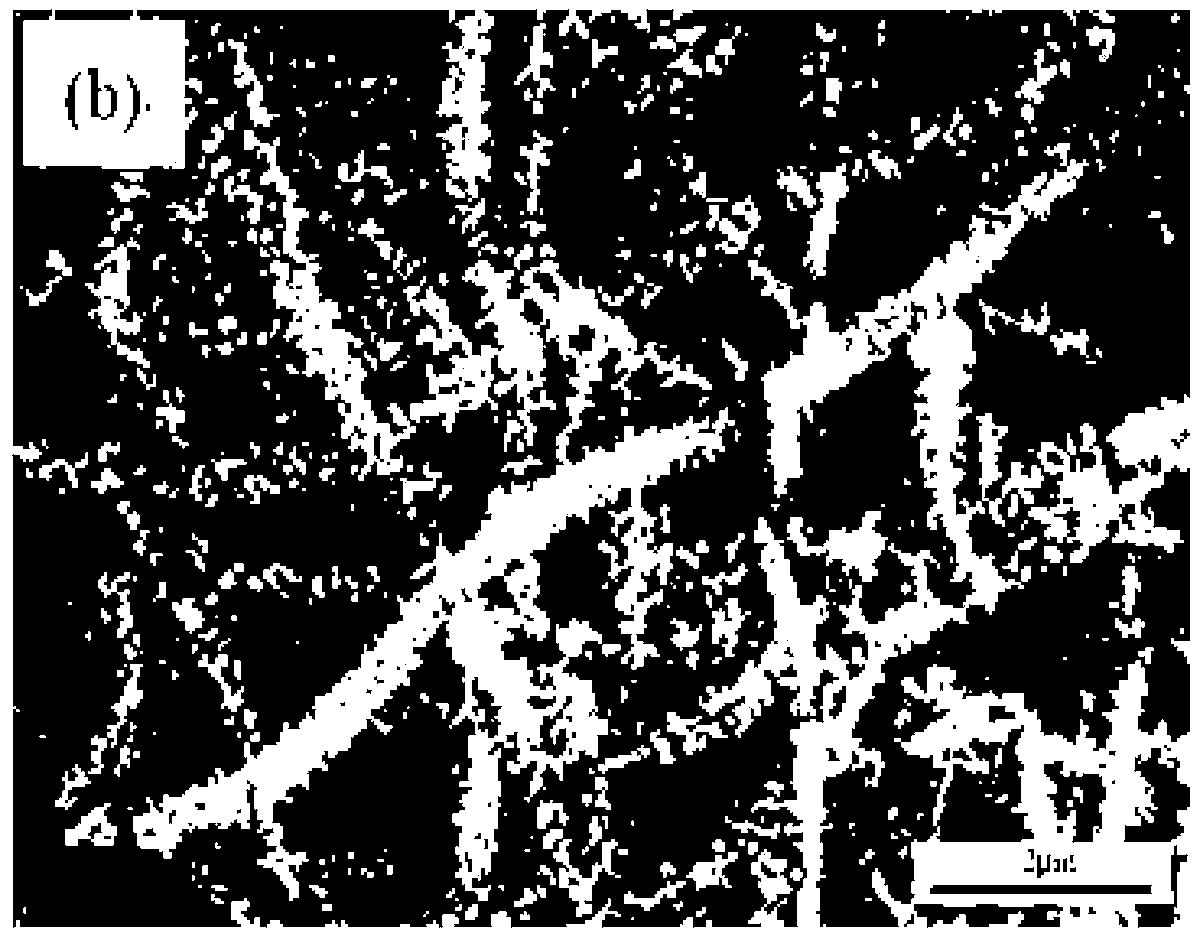

[0033] First, weigh 2.0 g of polyvinylpyrrolidone (PVP) and dissolve it in 15 g of dimethylformamide (DMF), and stir until the PVP is completely dissolved to obtain a transparent and clear solution. Take 5.68g of isobutyl titanate (TIP) and 2.4g of acetic acid and stir and mix to obtain another transparent and clear solution, then mix the above two solutions and stir evenly. Then add 1.38g tetraethyl orthosilicate solution and stir well to obtain the required electrospinning precursor solution, inject the precursor solution into a 10ml medical syringe for electrospinning. After electrospinning, the obtained electrospun product is placed in a muffle furnace for roasting to obtain a dual-phase SiO 2 (20wt%) / TiO 2 (80wt%) nanofibers, see figure 1 . A little biphasic SiO after roasting 2 / TiO 2 The nanofibers were placed into a vial containing NaOH (5M) solution, and then the vial was placed at 80 o C oven for 24 hours. Then filter and wash the nanofibers treated by NaOH et...

Embodiment 2

[0035] Weigh 2.0 g of polyvinylpyrrolidone (PVP) and dissolve it in 15 g of dimethylformamide (DMF), and stir until the PVP is completely dissolved to obtain a transparent and clear solution. Take isobutyl titanate (TIP) 7.82g and acetic acid 2.4g and stir and mix to obtain another transparent and clear solution, then mix the above two solutions and stir evenly. Then add 1.38g tetraethyl orthosilicate solution and stir well to obtain the desired quiet Electrospinning precursor solution, inject the precursor solution into a 10ml medical syringe for electrospinning. After electrospinning, the obtained electrospun product is put into a muffle furnace for roasting treatment to obtain biphasic SiO 2 (30wt%) / TiO 2 (70wt%) nanofibers. A little SiO after roasting 2 / TiO 2 The composite nanofibers were placed into a vial containing NaOH (5M), and then the vial was placed at 80 o C oven for 24 hours. Then filter and wash the nanofibers treated by NaOH etching to neutrality, an...

Embodiment 3

[0037] Weigh 2.0 g of polyvinylpyrrolidone (PVP) and dissolve it in 15 g of dimethylformamide (DMF), and stir until the PVP is completely dissolved to obtain a transparent and clear solution. Take 8.75g of isobutyl titanate (TIP) and 2.4g of acetic acid and stir and mix to obtain another transparent and clear solution, then mix the above two solutions and stir evenly. Then add 1.38g tetraethyl orthosilicate solution and stir well to obtain the required electrospinning precursor solution, inject the precursor solution into a 10ml medical syringe for electrospinning. After electrospinning, the obtained electrospun product is placed in a muffle furnace for roasting to obtain a dual-phase SiO 2 (40wt%) / TiO 2 (60wt%) nanofibers. A little SiO after roasting 2 / TiO 2 The composite nanofibers were placed into a vial containing NaOH (5M), and then the vial was placed at 80 o C oven for 24 hours. Then filter and wash the nanofibers treated by NaOH etching to neutrality, and then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com