Simulated aluminum sheet wallboard coated with ultraviolet-resistant coating and preparation method thereof

An anti-ultraviolet coating, imitation aluminum plate technology, applied in building components, buildings, building structures, etc., can solve the problems of poor precision, low strength, high cost, and achieve simple and reasonable preparation process, low process cost, and low water absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

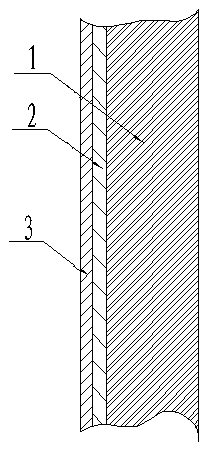

[0028] A kind of imitation aluminum plate wallboard coated with anti-ultraviolet coating, it comprises imitation aluminum plate base 1, imitation aluminum plate fluorocarbon paint coating 2, anti-ultraviolet coating 3, the outer surface of imitation aluminum plate base 1 contains a imitation aluminum plate fluorocarbon paint coating Layer 2, a layer of anti-ultraviolet coating 3 is sprayed on the imitation aluminum plate fluorocarbon paint coating 2;

[0029] Described anti-ultraviolet coating 3 is a commercially available anti-ultraviolet coating;

[0030] The aluminum imitation plate base layer 1 is made by mixing 65% by weight of coal gangue fiber particles, 20% by weight of polymer fireproof modified material, 10% by weight of silicon-aluminum clinker and 5% by weight of stearic acid.

[0031] A kind of preparation method of the imitation aluminum plate wallboard that is coated with anti-ultraviolet coating comprises the following steps:

[0032] (1) 50-75% by weight of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com