Total heat exchanger

A total heat exchanger and heat exchange core technology, which is applied in heating methods, household heating, household heating, etc., can solve the problems of uneven distribution, affect the heat exchange efficiency of the total heat exchanger, etc., and improve the flow path. structure, the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

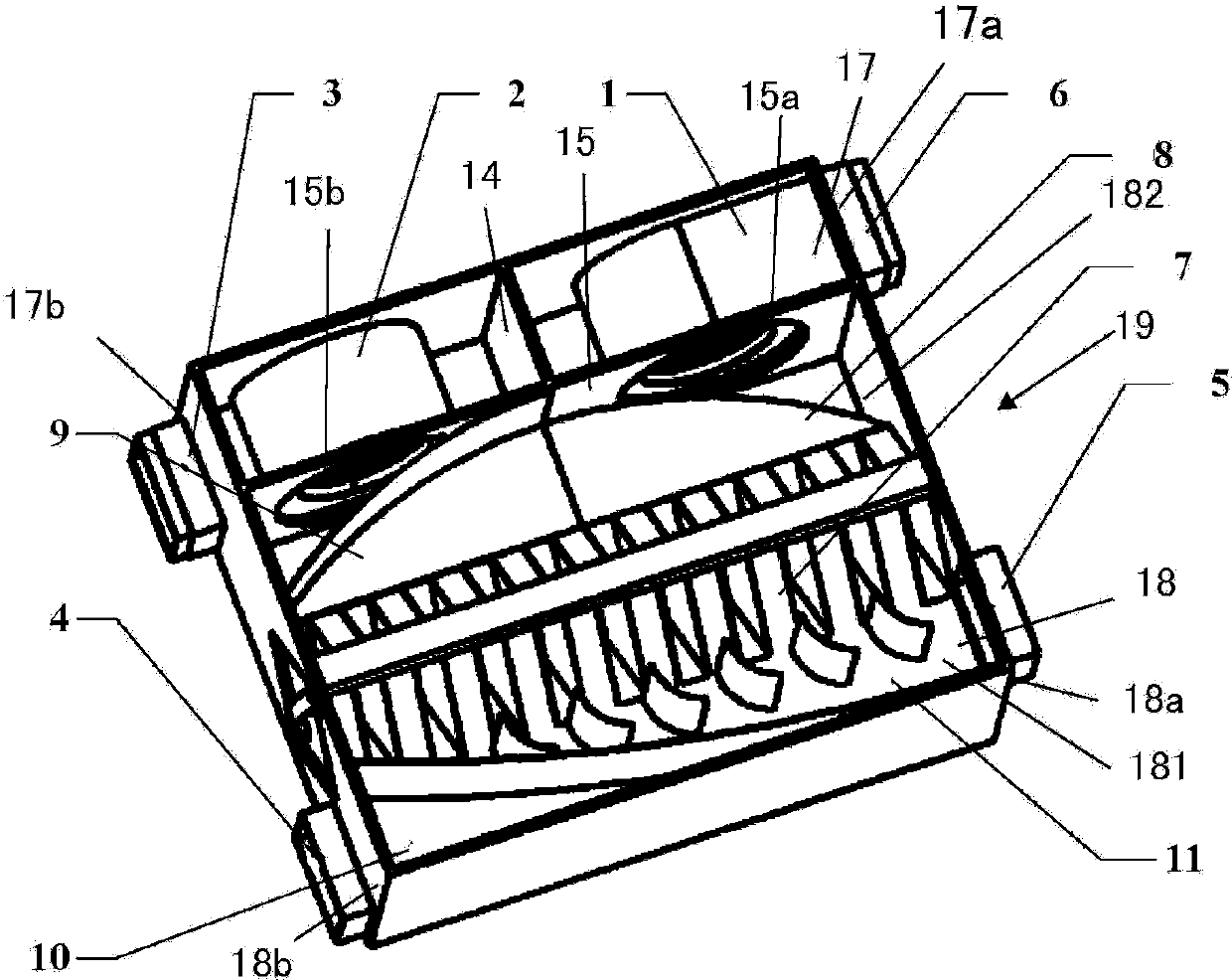

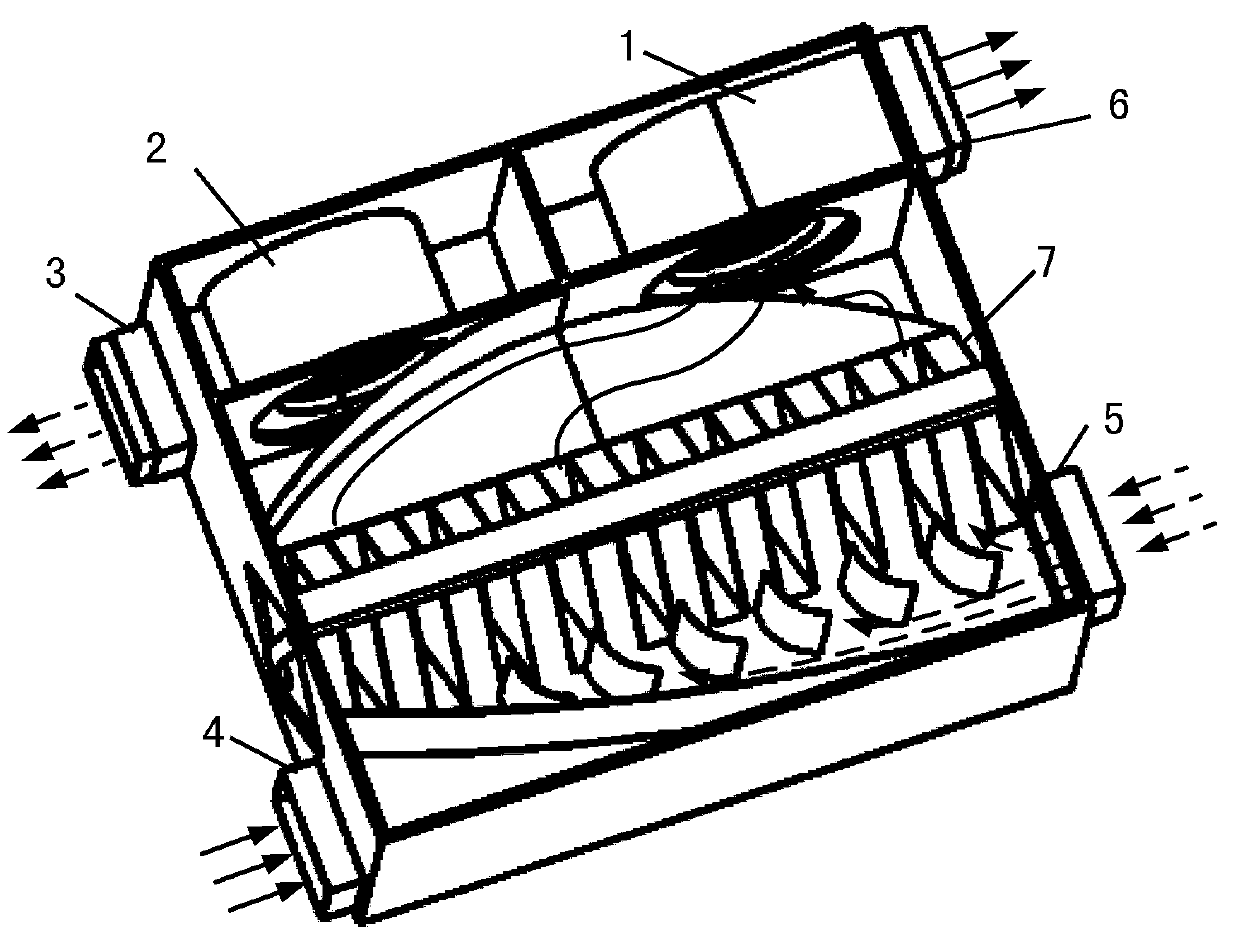

[0077] Using the present invention figure 1 The total heat exchanger shown measures its exchange efficiency. The measurement conditions are: indoor exhaust air dry bulb temperature 22.0±0.5°C, moisture content 10.5±0.5 g·kg -1 , outdoor fresh air dry bulb temperature 30.0±0.5℃, moisture content 15.8±0.5 g·kg -1 , using 7 splitters, the radian of the splitter is 105°, the tangent direction of the air inlet end of the splitter is parallel to the air inlet direction, and the tangent direction of the air outlet end is perpendicular to the windward surface of the core.

Embodiment 2

[0081] Using the present invention figure 1 The total heat exchanger shown measures its exchange efficiency. The measurement conditions are: the indoor exhaust air dry bulb temperature is 21.5±0.5°C, and the moisture content is 9.5±0.5 g·kg -1 , outdoor fresh air dry bulb temperature 13.5±0.5℃, moisture content 5.8±0.5 g·kg -1 , using 7 splitters, the radian of the splitter is 105°, the tangent direction of the air inlet end of the splitter is parallel to the air inlet direction, and the tangent direction of the air outlet end is perpendicular to the windward surface of the core.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com