Tube orifice diameter variable plug-in sampling instrument

A plug-in, sampler technology, applied in the direction of sampling devices, etc., can solve the problems of polluted samples, waste of treatment costs, time-consuming, etc., and achieve the effects of improving fidelity, reducing pressure gradients, and avoiding artificial pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

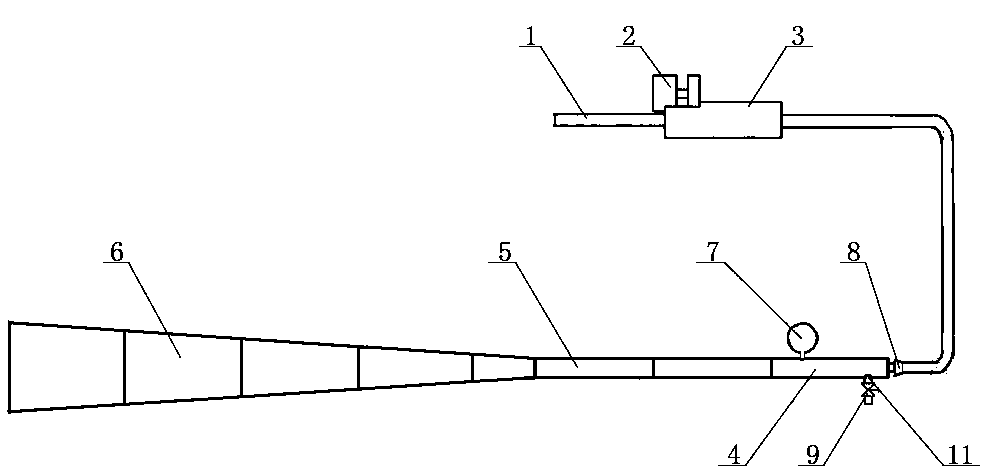

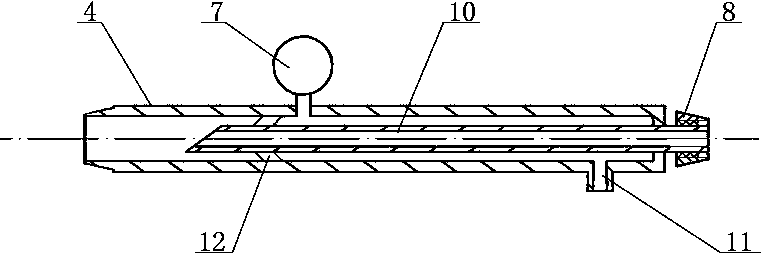

[0055] Such as figure 1 As shown, the sampler of the present invention includes multi-section conical tubes 6, multiple straight tubes 5, a steady-flow buffer tube 4, a core tube 10, a shunt pressure regulating valve 9, a pressure gauge 7, a sampling hose 1 and a concentric Type flow regulator and other components. Wherein, the tapered tube 6, the straight tube 5, the steady flow buffer tube 4 and the core tube 10 are all made of 304 stainless steel, and the sampling hose 1 is a pressure-resistant transparent hose made of silica gel.

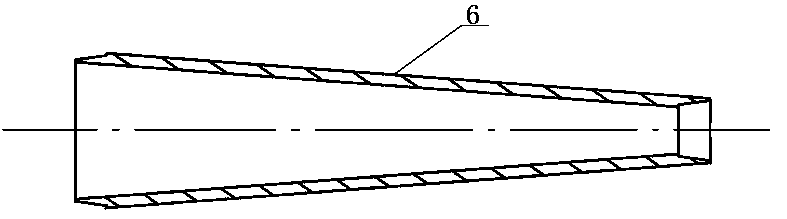

[0056] figure 2 Among them, the tapered pipe 6 can be configured with 4-6 sections, and the taper is best controlled at 6.5°~7°. The taper of each section of the tapered pipe is the same, and the five sections of the tapered pipe can be connected to each other through their respective threaded ports in turn to form a combination Cone. For the pump tube with smaller diameter used on site, according to the actual situation, the large-sized con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com