On-line oil filter device and method for main transformer on-load switch with intelligent frequency conversion function

A functional and intelligent technology, applied in the field of main transformer on-load switch on-line oil filter device, can solve the problems of on-load switch burnt main transformer trip, Buchholz relay heavy-watt action, unable to automatically control the operation, etc., to reduce the speed and running time. , The effect of reducing the number of power outages and reducing the maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

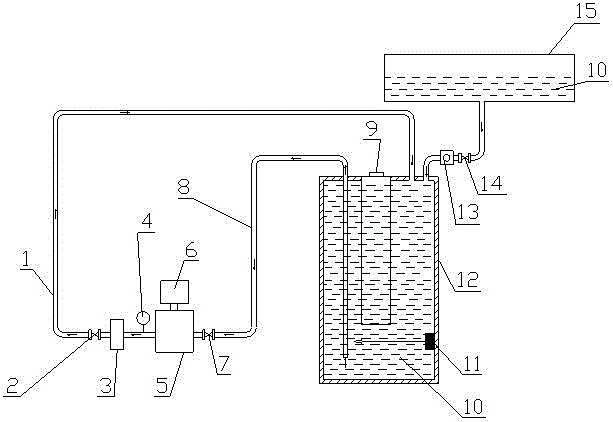

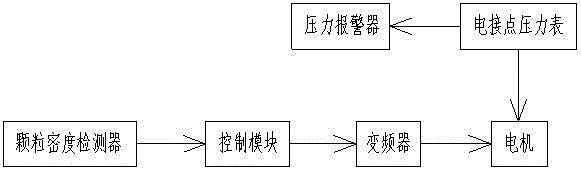

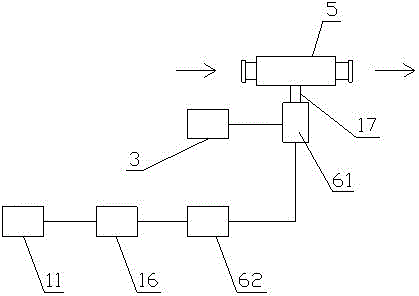

[0026] like Figures 1~11 As shown in the figure, a main transformer on-load switch online oil filtering device with intelligent frequency conversion function includes an oil pump driven by a frequency conversion motor and a particle density detector for detecting the transformer oil in the oil storage barrel. The frequency conversion motor is composed of A frequency converter is connected with a motor, the oil inlet of the oil pump is connected with an oil inlet pipe that penetrates into the oil storage barrel, the oil inlet pipe is provided with an oil inlet valve, and the oil outlet of the oil pump is connected with an oil inlet pipe leading to the storage tank. The oil outlet pipe of the oil drum is provided with an oil outlet valve, a filter tank and an electric contact pressure gauge. The electric contact pressure gauge is connected to the frequency conversion motor and the pressure alarm. The frequency converter of the frequency conversion motor and the particle density ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com