Cooling plate, fuel cell and fuel cell system

A fuel cell and cooling plate technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell components, etc., can solve problems such as low power efficiency and low local current density, and achieve low manufacturing costs, guaranteed service life, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

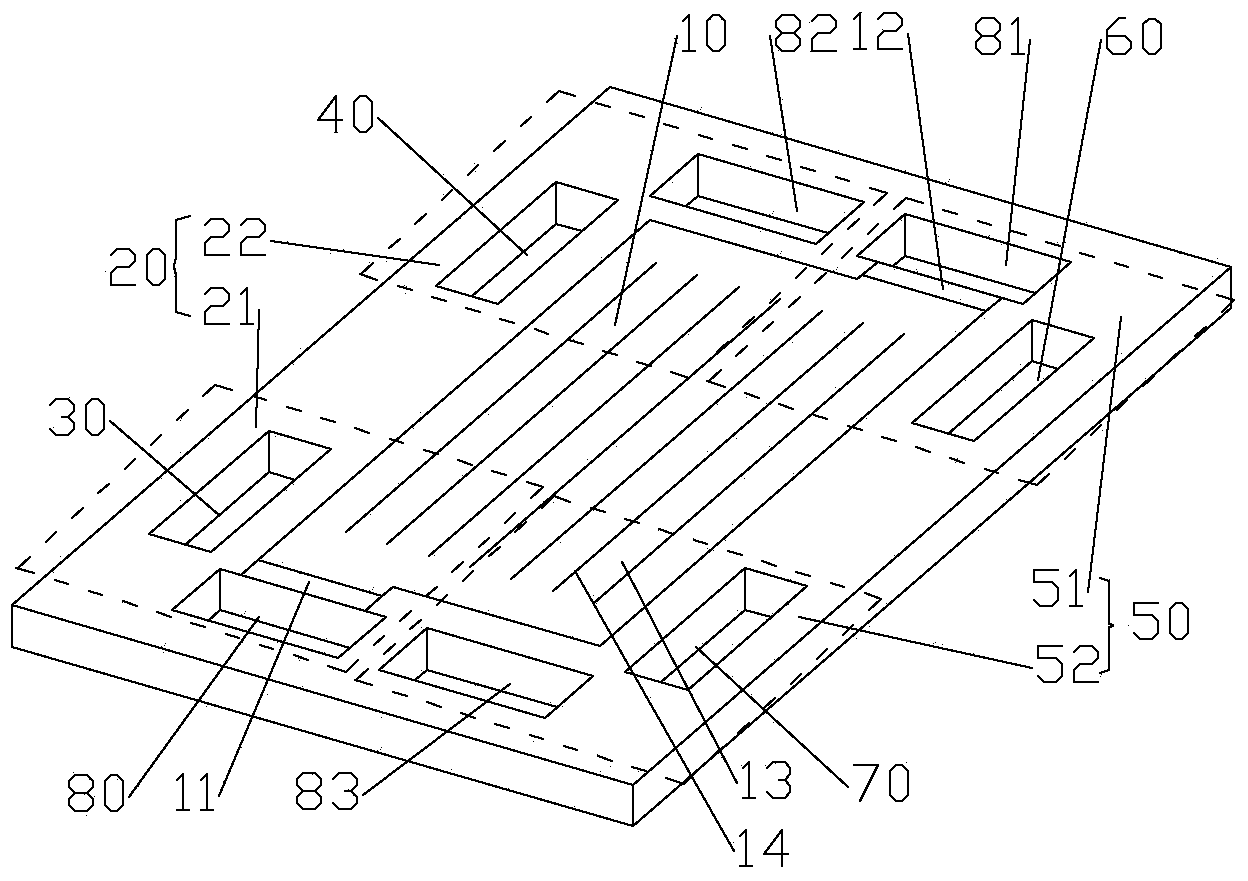

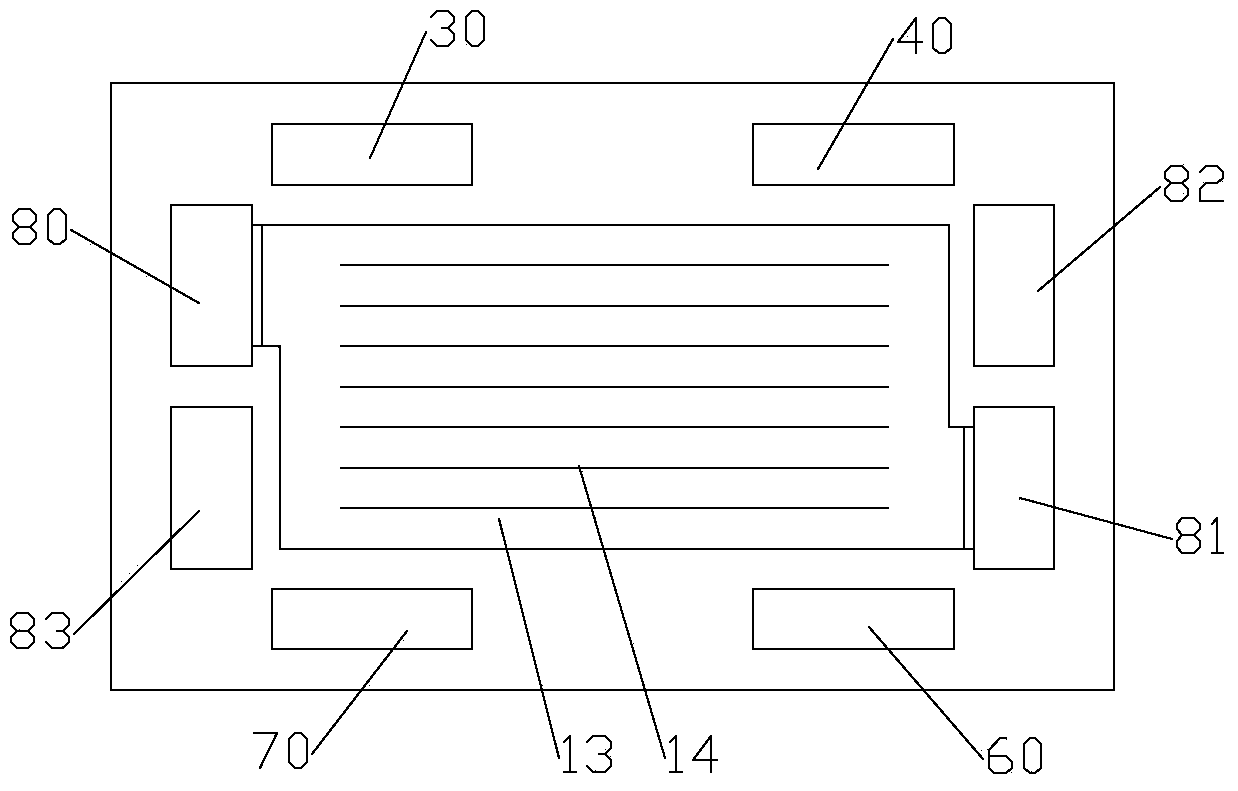

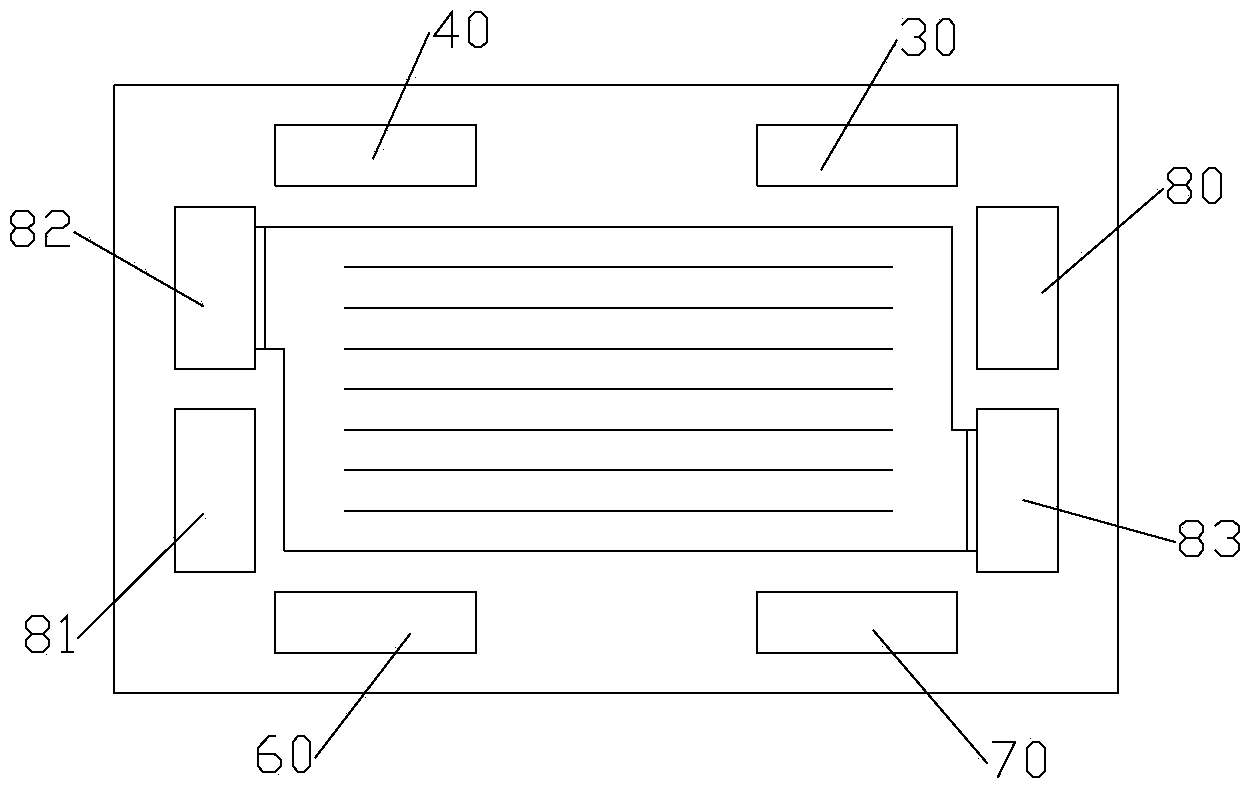

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0030] As a first aspect of the present invention, a cooling plate is provided. Such as Figures 1 to 5 As shown, the cooling plate includes multiple cooling channels 10 , and the coolant inlets 11 of at least two cooling channels 10 in the multi-channel cooling channels 10 are set in the local reaction high temperature zone 20 . Since there are multiple cooling channels 10, the coolant inlets of the multiple cooling channels 10 can be correspondingly provided in the local reaction high temperature zone 20 according to the reaction conditions of the fuel cell 100, thereby controlling the local reaction high temperature zone of the fuel cell 100. Targeted multi-point cooling is performed to ensure the water content of the proton exchange membrane, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com