Honey pomelo stuffing, and preparation method and application thereof

A technology of honey pomelo and stuffing, applied in application, baking, confectionery, etc., can solve problems such as limitations, achieve the effect of increasing quantity, improving utilization rate, and sweet but not greasy taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

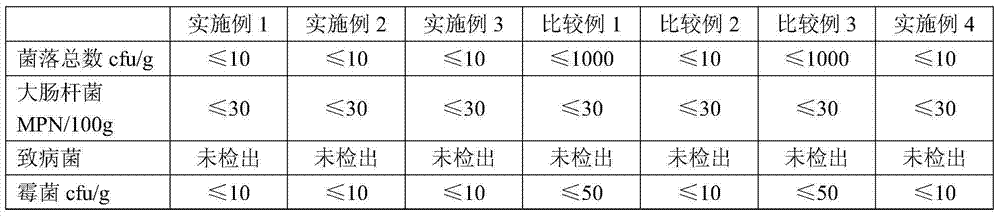

Examples

Embodiment 1

[0057] The honey pomelo filling granules are prepared by the following methods of debittering pomelo peel by masking, debittering pomelo fruit by ion exchange resin and vacuum sugaring.

[0058] (1) Preparation of debitter pomelo peel:

[0059] Honey pomelo peel forming steps: divide the honey pomelo fresh fruit into slices, and separate the honey pomelo peel from the honey pomelo pulp, cut the honey pomelo peel into standard-shaped honey pomelo dices, and the honey pomelo peel enters the machine Dice, cut into diced honey pomelo fruit with the specification of (3-4cm)×(3-4cm)×(3-4cm), and then send it to the diced honey pomelo fruit grading device to obtain qualified diced honey pomelo fruit.

[0060] Debittering step of honey pomelo peel: under a vacuum degree of 0.05MPa, the debittering solution is used to remove the bitterness in the diced pomelo, and the debittered diced pomelo is separated from the debittering solution. The proportion of the debittering liquid is as fol...

Embodiment 2

[0072] The process of this embodiment is basically the same as Embodiment 1, the difference is:

[0073] In the step of preparing debitter pomelo peel, add the step of cleaning and disinfection before the step of forming the pomelo peel: the fresh pomelo fruit is automatically cleaned in hot water at 40-45°C for 2-3 minutes, then cooled and rinsed in clean water, at a concentration of 100mg / L chlorine dioxide solution at room temperature for disinfection and drying.

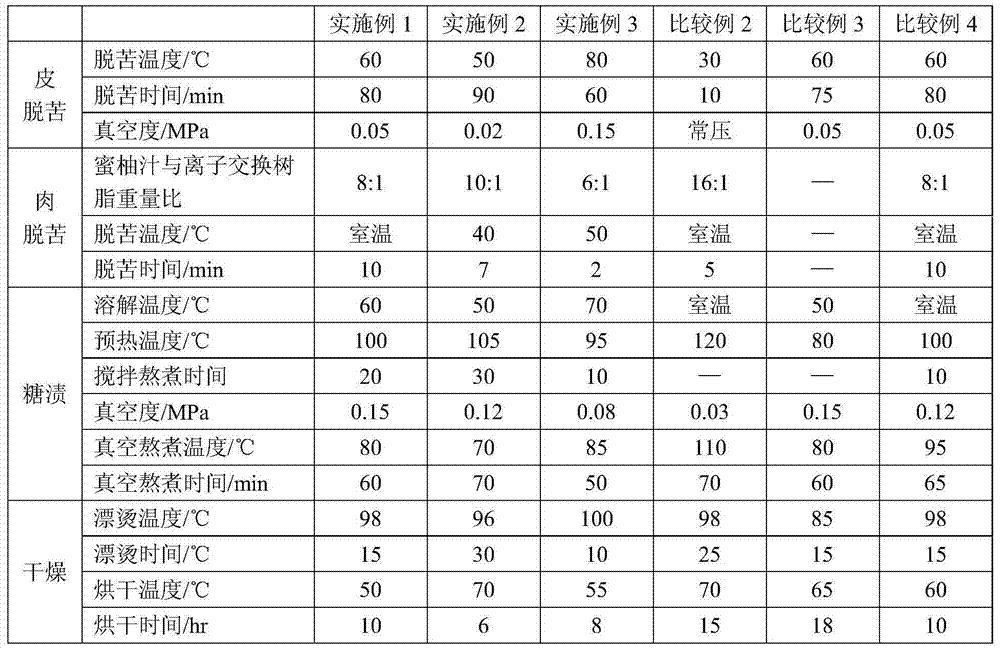

[0074] In addition, see Table 1 and Table 2 for the adjustment of specific formulations and process parameters.

Embodiment 3

[0076] The process of this embodiment is basically the same as that of Example 1, and the adjustments of specific formulas and process parameters are shown in Table 1 and Table 2.

[0077] Table 1 formula ratio

[0078] components

Example 1

Example 2

Example 3

Comparative example 2

Comparative example 3

Comparative example 4

water

10

8

12

10

20

10

Debittered Pomelo Juice

20

22

18

—

10

15

5

4

6

25

15

5

15

16

14

15

15

15

Citric acid monohydrate

0.8

0.7

0.9

0.1

—

0.8

licorice

0.03

0.02

0.05

—

1.03

0.03

Vitamin C

0.05

0.03

0.06

0.05

0.05

0.05

Potassium sorbate

0.02

0.035

0.04

0.035

0.02

0.035

Debitter pomelo peel

50

45

55

45

50

50

[0079] Table 2 Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com