Seasoning powder and preparation method thereof

A technology of seasoning powder and powder, which is applied in the direction of food preparation, food ingredients as a taste improver, and the function of food ingredients, etc. It can solve the problems of restricting the application of pure chicken powder, and achieve the effect of fresh and pleasant taste, unique taste and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

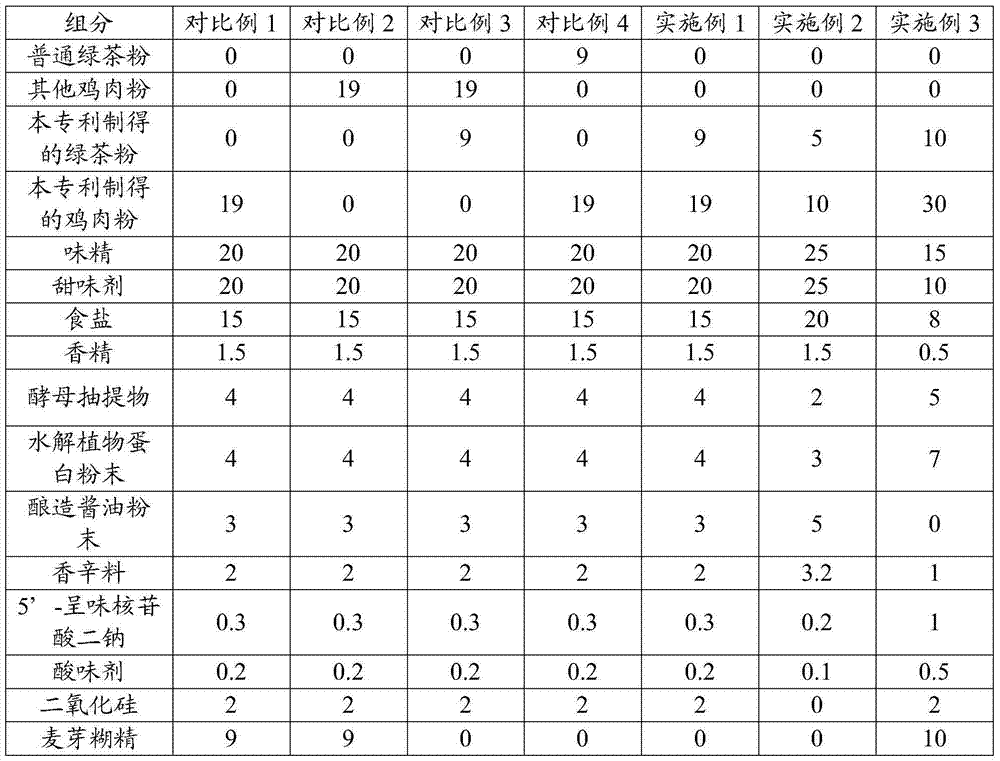

[0042] A seasoning powder, mainly prepared from the following raw materials by weight:

[0043] Green tea powder, chicken powder, monosodium glutamate, sweetener, salt, brewed soy sauce powder, hydrolyzed vegetable protein powder, yeast extract, spices, essence, silicon dioxide, 5'-flavored nucleotide disodium, sour agent and Maltodextrin, please refer to Table 1 for specific dosage;

[0044] The preparation method of the green tea powder comprises the following steps: crush the green tea leaves to 75-85 mesh to obtain tea powder, add 25-35 times of pure water according to the weight of the tea powder, mix, pass through a colloid mill, and grind the teeth of the colloid mill The gap is 6-8μm to get the ultra-fine pulverized tea slurry, let it stand still, centrifuge at a speed of 3800-4200r / min, remove water, and vacuum-dry it for 150min at a vacuum degree of -0.1Mpa and a temperature of 90°C to obtain Superfine green tea powder.

[0045] The preparation method of described ...

Embodiment 2

[0055] A seasoning powder, mainly prepared from the following raw materials by weight:

[0056] Green tea powder, chicken powder, monosodium glutamate, sweetener, salt, brewed soy sauce powder, hydrolyzed vegetable protein powder, yeast extract, spices, essence, silicon dioxide, 5'-flavored nucleotide disodium, sour agent and Maltodextrin, please refer to Table 1 for the specific dosage;

[0057] The preparation method of the green tea powder, the steps are: crush the green tea leaves to 75-85 mesh to obtain tea powder, add 10 times of pure water according to the weight of the tea powder, mix, pass through a colloid mill, and the grinding teeth gap of the colloid mill is 6-8μm ultrafine tea slurry, let it stand, centrifuge at a speed of 3800-4200r / min, remove water, and vacuum-dry for 180min at a vacuum degree of -0.05Mpa and a temperature of 70°C to obtain the final product.

[0058] The preparation method of described chicken powder comprises the following steps:

[0059] ...

Embodiment 3

[0067] A seasoning powder, mainly prepared from the following raw materials by weight:

[0068] Green tea powder, chicken powder, monosodium glutamate, sweetener, salt, brewed soy sauce powder, hydrolyzed vegetable protein powder, yeast extract, spices, essence, silicon dioxide, 5'-flavored nucleotide disodium, sour agent and Maltodextrin, please refer to Table 1 for the specific dosage;

[0069] The preparation method of described green tea powder, the steps are: the green tea leaves are pulverized to 75-85 order, obtain tea powder, add 50 times of pure water by the weight of tea powder, mix, pass colloid mill, the grinding tooth clearance of colloid mill is 6-8μm ultrafine tea pulp, let it stand, centrifuge at a speed of 3800-4200r / min, remove water, and vacuum-dry for 60min at a vacuum degree of -0.15Mpa and a temperature of 100°C to obtain the final product.

[0070] The preparation method of described chicken powder comprises the following steps:

[0071] (1) Material p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com