Die and method for forming straight tube section-expansion section composite titanium alloy equal-wall-thickness curved generatrix thin wall rotation body component

A technology of forming molds and constant wall thickness, which is applied in the field of precision thermoforming of hard-to-deform materials, can solve the problems of severe wall thickness reduction, easy axial cracking, and drop, etc., to improve the overall performance and slow down the cracking defects of the mouth The effect of generating trends and increasing the expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

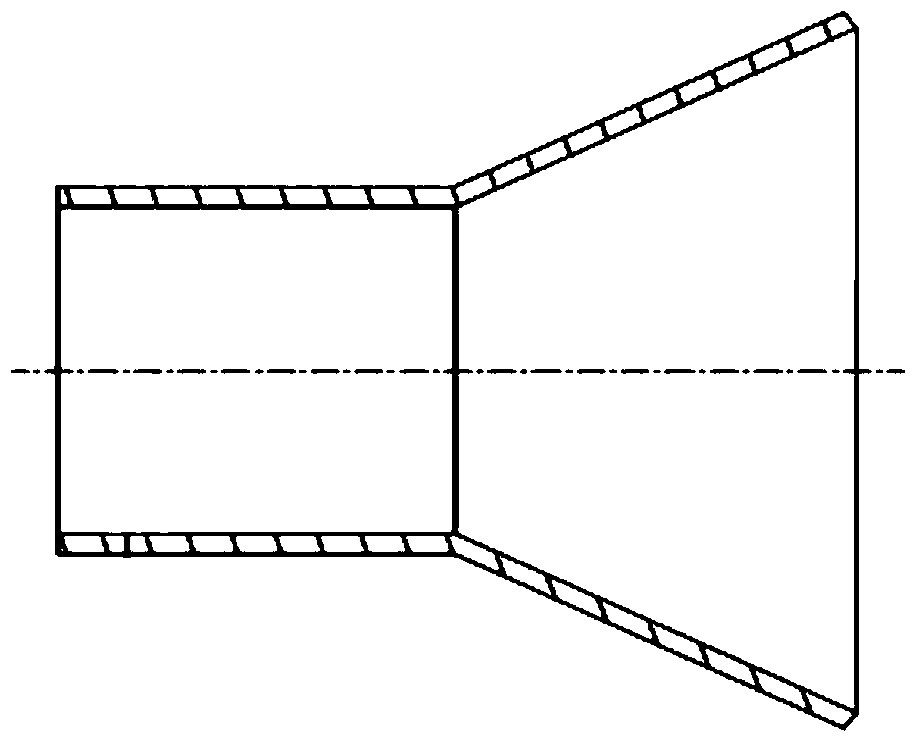

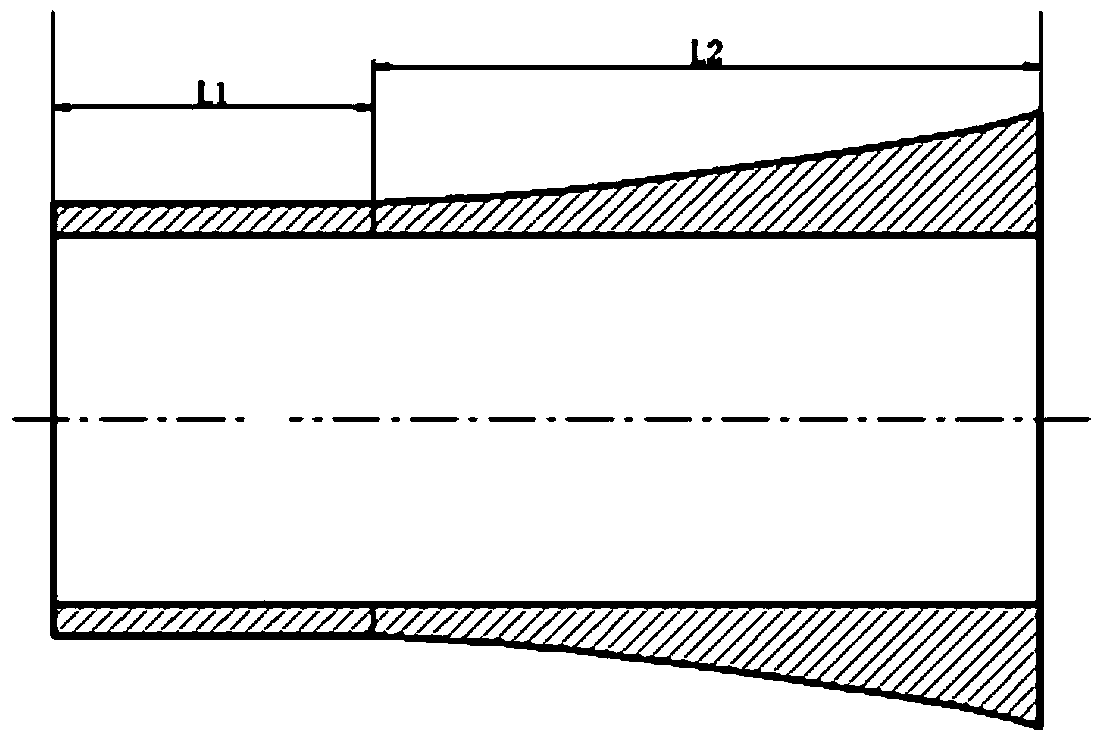

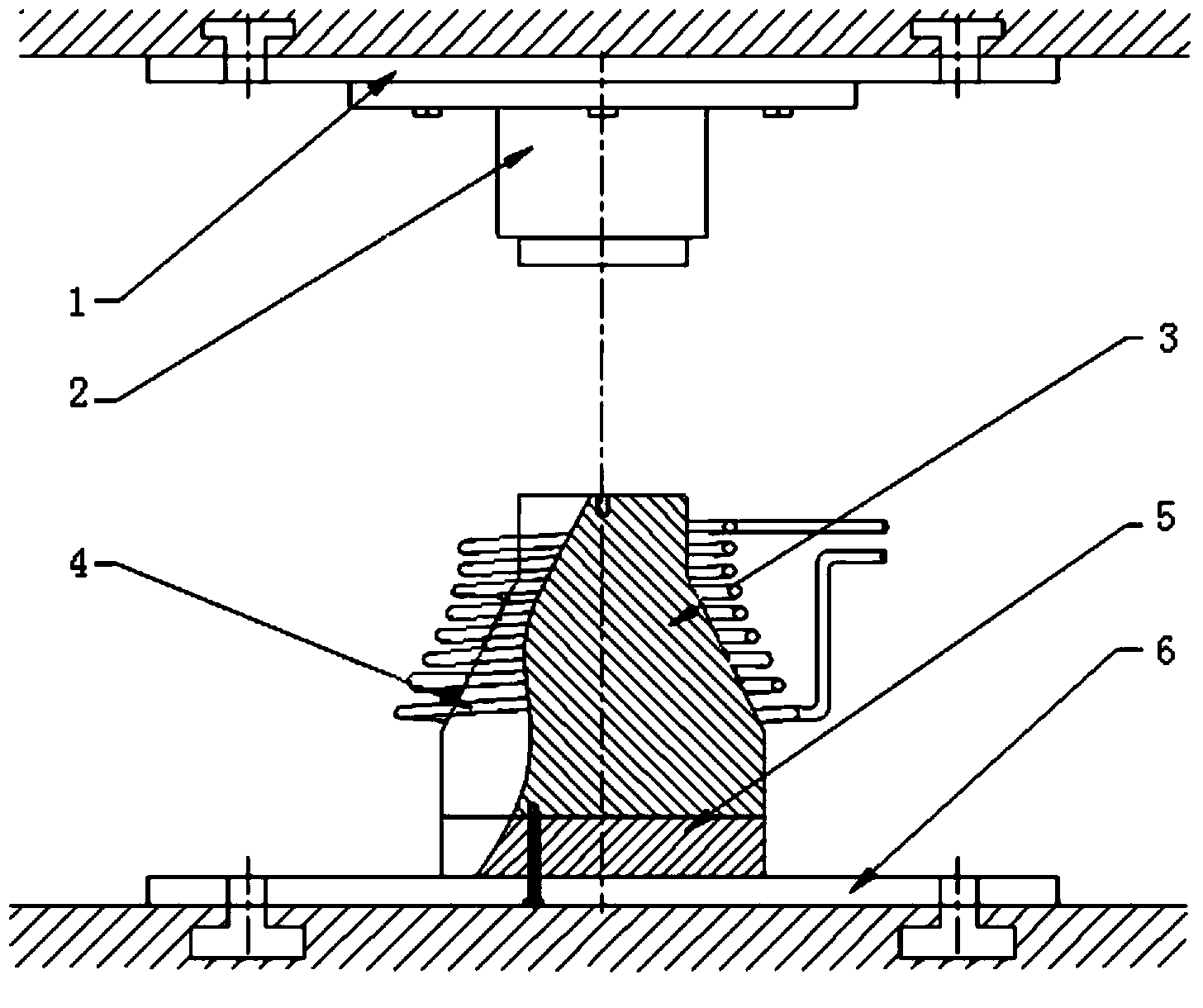

[0023] Specific embodiment 1: A mold for forming a straight cylinder-expanding section composite titanium alloy equal-wall thickness curved generatrix thin-walled rotary member consists of an upper template 1, an upper mold 2, a lower mold 3, an induction heating device 4, The heat insulating ring 5 and the lower template 6 are composed; the upper mold 2 is located at the lower part of the upper template 1, the upper mold 2 is divided into upper and lower parts, and the upper and lower parts are coaxially connected as a whole. The outer diameter of the small end of the front wall-thickness tube billet is small, and the lower part is cylindrical with a diameter smaller than the upper part. The three parts are connected in turn to form a coaxial integrated structure. The upper part of the lower mold 3 is cylindrical, and the diameter of the upper cylindrical shape of the lower mold 3 matches the inner diameter of the wall thickness tube billet before thermal processing after turn...

specific Embodiment approach 2

[0024] Embodiment 2: A method of forming a straight cylinder-expansion section composite titanium alloy equal-wall thickness curved generatrix thin-walled rotary member in this embodiment is carried out according to the following steps:

[0025] 1. Calculate the theoretical geometric shape and size of the variable wall thickness shell and determine the actual geometric shape and size of the variable wall thickness shell: based on the law of constant volume in the plastic processing process, calculate the theoretical volume of the target workpiece according to the geometric shape and size of the target workpiece, that is, the variable The theoretical volume of the wall-thickness shell, and then make a waste section reserved at both ends of the axial direction of the determined theoretical geometric shape of the variable-wall-thickness shell, and then use it as the actual geometric shape of the variable-wall-thickness shell; The ratio of the axial length of the constant wall thic...

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment is different from Embodiment 2 in that: the axial ends of the billet described in step 1 respectively reserve a waste section with a length of 10 mm to 20 mm. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com