Numerical control machine tool

A technology of CNC machine tools and racks, which is applied in the direction of metal processing machinery parts, driving devices, metal processing equipment, etc., can solve the problems that affect the processing accuracy, cannot adjust the speed, and cannot meet the processing requirements, so as to improve the processing accuracy and torque. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

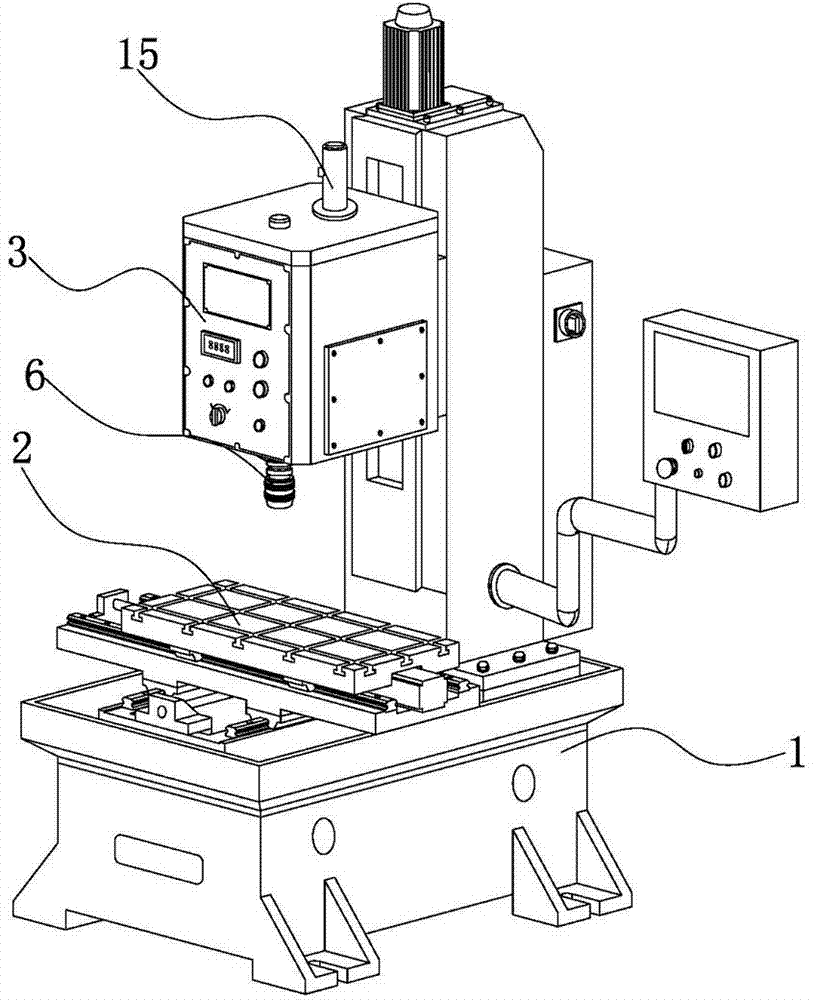

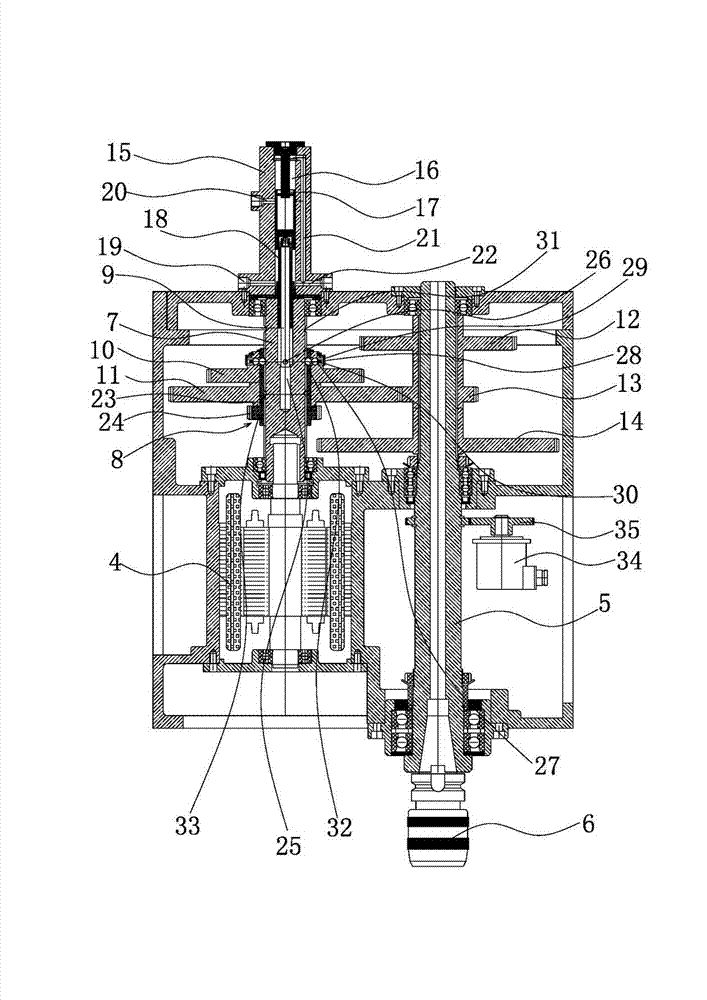

[0020] Such as figure 1Or as shown in Figure 2, the CNC machine tool is mainly composed of a frame 1 and a workbench 2 arranged on the frame 1, and a device is arranged between the workbench 2 and the frame 1 so that the workbench 2 can be placed on the frame 1 along the X Axis, the linkage device that Y axis direction moves, this linkage device is prior art, is basically identical with the linkage device in the background technology; The frame 1 opposite to workbench 2 is provided with cutter transmission control box 3, and cutter transmission control box 3 and the frame 1 are provided with an up and down lifting device that makes the tool transmission control box 3 move along the Z-axis direction of the frame 1. The up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com