Polishing mechanism with polishing function for ceramic tile cutting machine

A polishing mechanism and cutting machine technology, applied in surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding workpiece edges, etc. problems, to achieve the effect of simplifying the production process, improving the impact force, and improving the adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

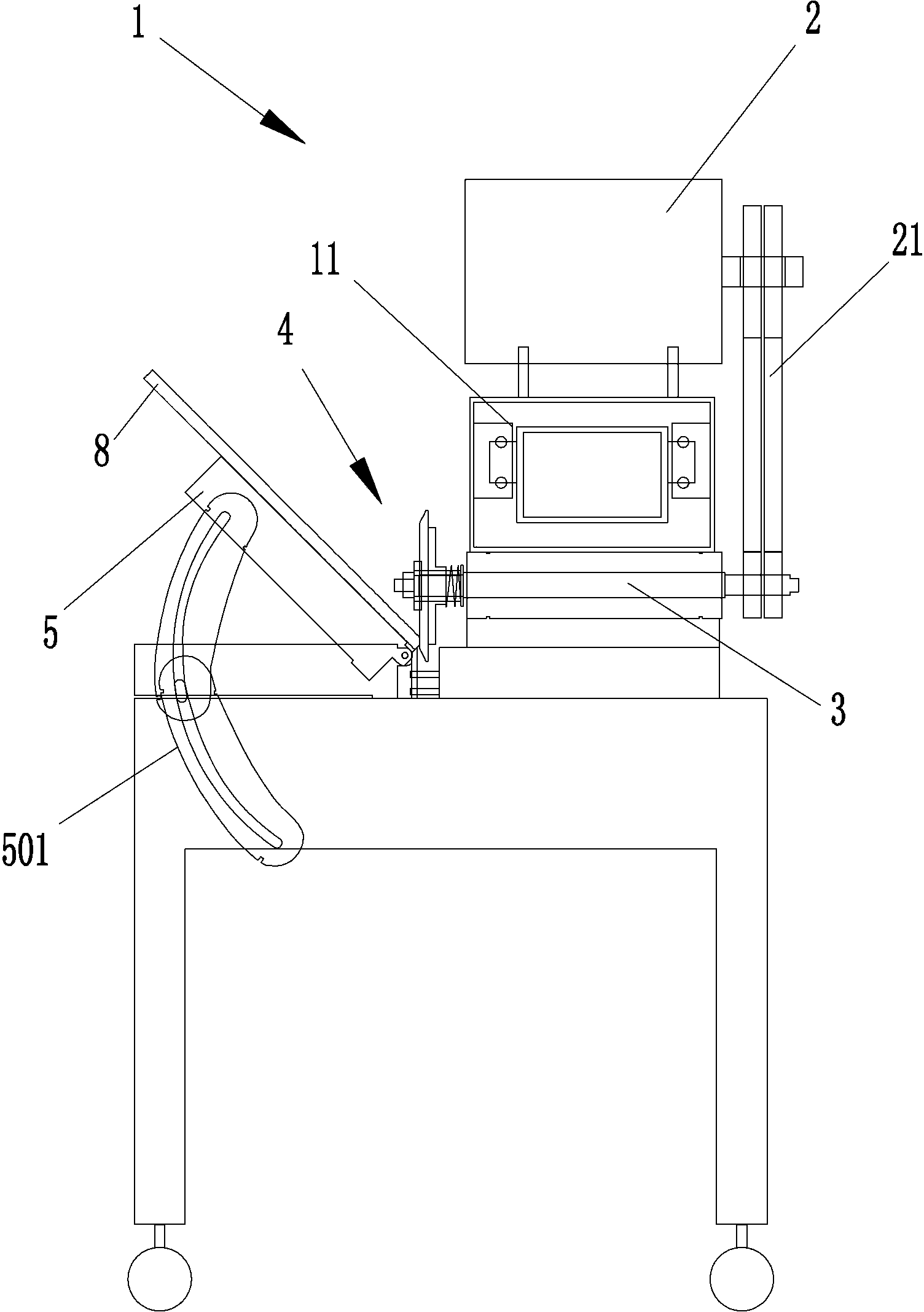

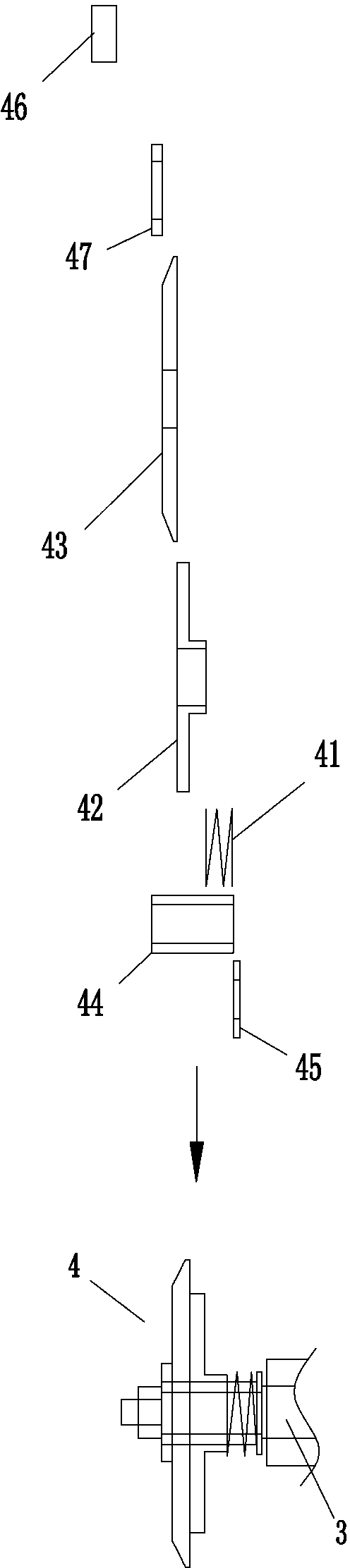

[0016] Embodiment 1: see attached figure 1 to attach figure 2 As shown, the polishing mechanism of the ceramic tile cutter with polishing function described in the present embodiment includes an organic case 1, a motor 2, a polishing shaft 3 and a polishing assembly 4, wherein a motor 2 is installed on the upper end of the case 1, and the polishing The shaft 3 is built in the lower end of the chassis 1, the motor 2 is connected to one end of the polishing shaft through a transmission belt 21, the other end of the polishing shaft 3 extends out of the chassis 1 and is matched with the polishing assembly 4, and the polishing assembly 4 includes a spring 41 , grinding disc suction cup 42, the water grinding disc 43 attached to the grinding disc sucker 42 disc surface, the suction cup chute ring 44 with multiple convex bodies 441, the pressure regulating plate 45, the limit nut 46 and the rubber ring 47, the described The side surface of the water grinding plate 43 is trapezoidal...

Embodiment 2

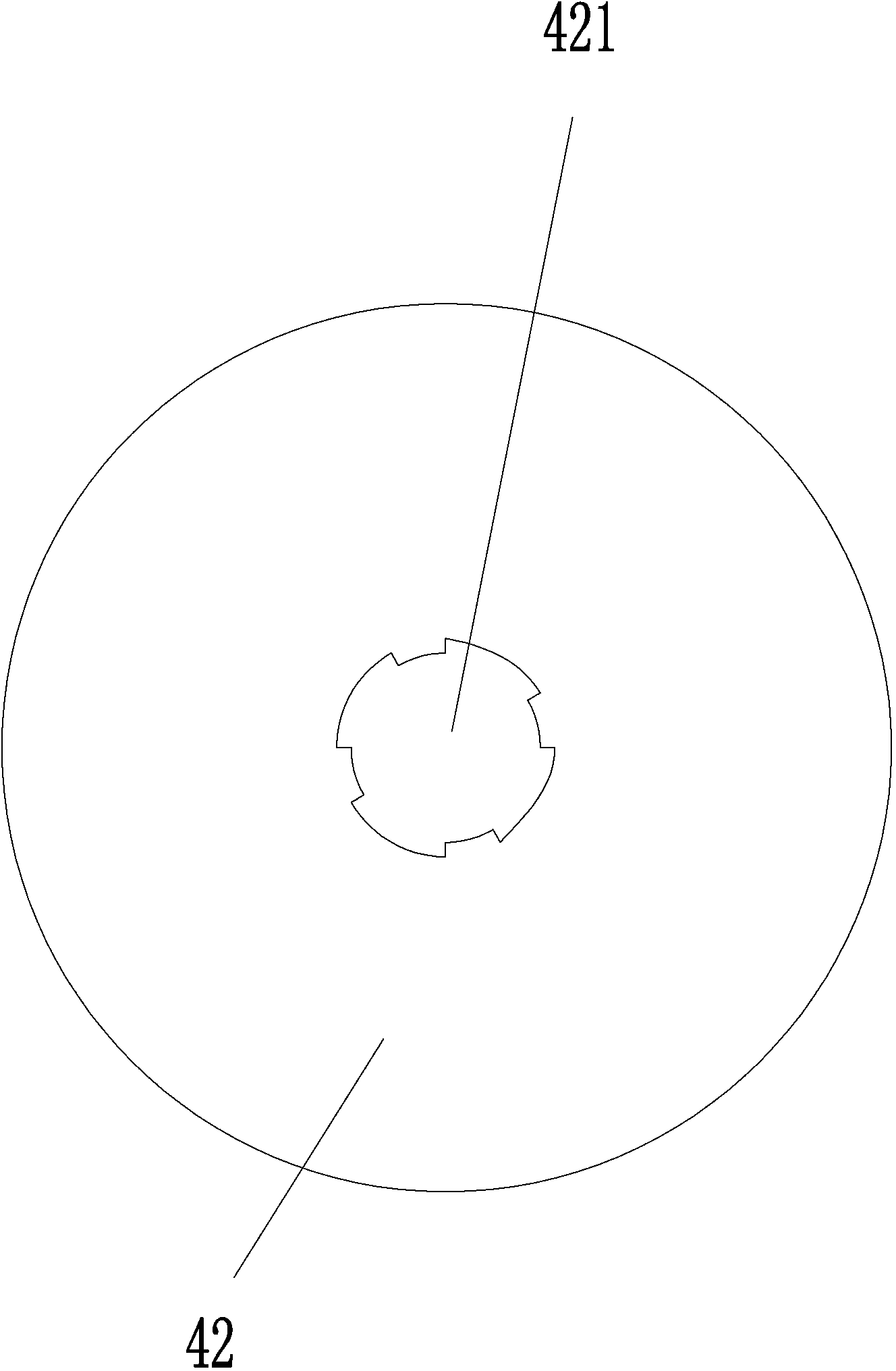

[0018] Embodiment 2: see attached image 3 to attach Figure 4 The difference between this embodiment and Embodiment 1 is that the protruding end surface of the polishing shaft 3 of the polishing mechanism has a plurality of convex strips 31 (or grooves) integrally formed, and the convex strips 31 and the disk surface are attached with a water abrasive sheet 43 The center of the grinding disc suction cup 42 is provided with a mounting hole 421 matched with the convex strip 31 (or groove). When the chamfer surface of the ceramic tile 8 to be polished contacts the water grinding disc 43, the grinding disc sucker 42 can extend along the polishing axis 3. When the outlet end moves horizontally on the surface, the spring 41 will shrink, thereby achieving the effect of automatic pressure regulation.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap