Double-faced adhesive production process for PVC (polyvinyl chloride) sail cloth

A production process and double-sided sticking technology, applied in layered products, lamination devices, lamination auxiliary operations, etc., can solve the problem of long residence time of base film and mask, brittle and yellow PVC tarpaulin, tarpaulin Low peel strength and other issues, to achieve good mechanical properties, avoid excessive heating, and low preheating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

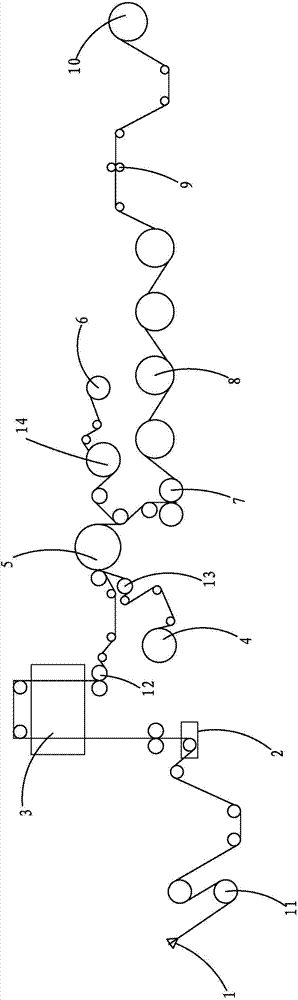

[0020] The specific implementation of the present invention will be further described below in conjunction with the examples and drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0021] The present invention is a production process for double-sided stickers of PVC tarpaulin. The production method sequentially includes the following steps:

[0022] S1. Mesh preheating: The mesh cloth unwinded on the mesh unwinding machine 1 is dried by the mesh preheating roller 11 to remove water, and the temperature of the mesh preheating roller is 100~105℃;

[0023] S2. Mesh gluing: Dip the dried mesh in a dipping tank 2 containing PU paste or PVC paste, and then flatten the surface sizing material after passing through a pair of embossing rollers;

[0024] S3. Drying of the mesh: Lead the mesh into the vertical furnace 3 for drying, and the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com