Supramolecular polymer thickening agent and preparation method thereof

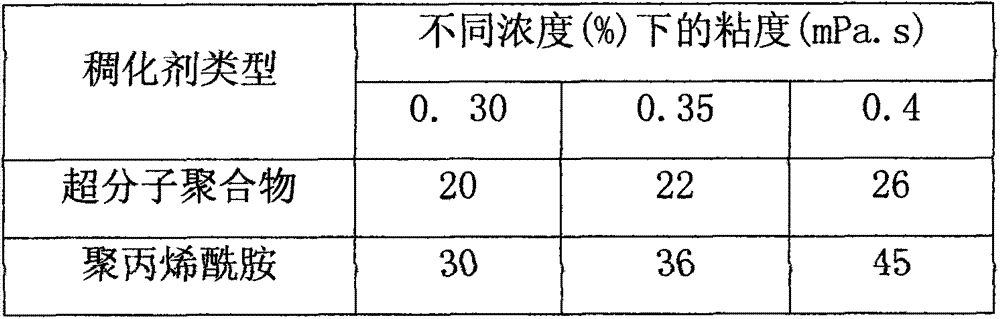

A supramolecular polymer and thickener technology, applied in the field of polymer materials, can solve problems such as poor temperature resistance and poor shear stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A supramolecular polymer thickener, which comprises the following raw materials formulated in parts by weight: 3.3 parts of acrylamide, 3.3 parts of vinylpyrrolidone, 1.4 parts of functionalized skeleton monomers, 12 parts of deionized water, 0.5 part of dispersant, 0.8 part of hydrophobic monomer, 20 parts of nitrogen and 0.05 part of initiator; the hydrophobic monomer is vinyl acetate; the functionalized backbone monomer is polyethyleneimine; the dispersant is polyethylene glycol ; The initiator is azobisisobutyronitrile. This preparation method comprises the steps:

[0037] 1. Dissolve acrylamide, vinylpyrrolidone and polyethyleneimine in deionized water in turn to prepare a 40% deionized aqueous solution;

[0038] 2. Mix polyethylene glycol with 40% deionized aqueous solution in step 1 to prepare a dispersant solution;

[0039] 3. Slowly add vinyl acetate into the dispersant solution in step 2 at a rate of 0.2mL / s, and mix evenly to make a suspension;

[0040]4. ...

Embodiment 2

[0043] A supramolecular polymer thickener, which comprises the following raw materials formulated in parts by weight: 3.3 parts of acrylamide, 3.3 parts of vinylpyrrolidone, 1.4 parts of functionalized skeleton monomers, 12 parts of deionized water, 0.8 parts of dispersant, 0.9 parts of hydrophobic monomer, 20 parts of nitrogen and 0.08 part of initiator; the hydrophobic monomer is methyl acrylate; the functionalized backbone monomer is polyaspartic acid; the dispersant is polyacrylamide Described initiator is benzoyl peroxide; Preparation method comprises the steps:

[0044] 1. Dissolve acrylamide, vinylpyrrolidone and polyaspartic acid in deionized water in sequence to prepare a 40% deionized aqueous solution;

[0045] 2. Mix polyacrylamide with 40% deionized aqueous solution in step 1 to prepare a dispersant solution;

[0046] 3. Slowly add methyl acrylate into the dispersant solution in step 2 at a rate of 0.2mL / s, mix evenly, and make a suspension;

[0047] 4. Place the...

Embodiment 3

[0050] A supramolecular polymer thickener, which comprises the following raw materials formulated in parts by weight: 3.3 parts of acrylamide, 3.3 parts of vinylpyrrolidone, 1.4 parts of functionalized skeleton monomers, 12 parts of deionized water, 0.5-1 part of dispersant, 1 part of hydrophobic monomer, 20 parts of nitrogen and 0.1 part of initiator; the hydrophobic monomer is methyl methacrylate; the functionalized backbone monomer is polyaspartic acid; the dispersant Be polyethylene glycol; Described initiator is azobisisobutyronitrile; Preparation method comprises the steps:

[0051] 1. Dissolve acrylamide, vinylpyrrolidone and polyaspartic acid in deionized water in sequence to prepare a 40% deionized aqueous solution;

[0052] 2. Mix polyethylene glycol with 40% deionized aqueous solution in step 1 to prepare a dispersant solution;

[0053] 3. Slowly add methyl methacrylate into the dispersant solution in step 2 at a rate of 0.2mL / s, and mix evenly to make a suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com