Internal heat exchange type material pyrophorisity test device with cutting knife safety control component

A technology of safety control and testing device, applied in the direction of chemical analysis using combustion, can solve problems such as inability to use heat test, heating device safety is not up to standard, etc., to achieve the effect of reducing energy consumption, safety and automation, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

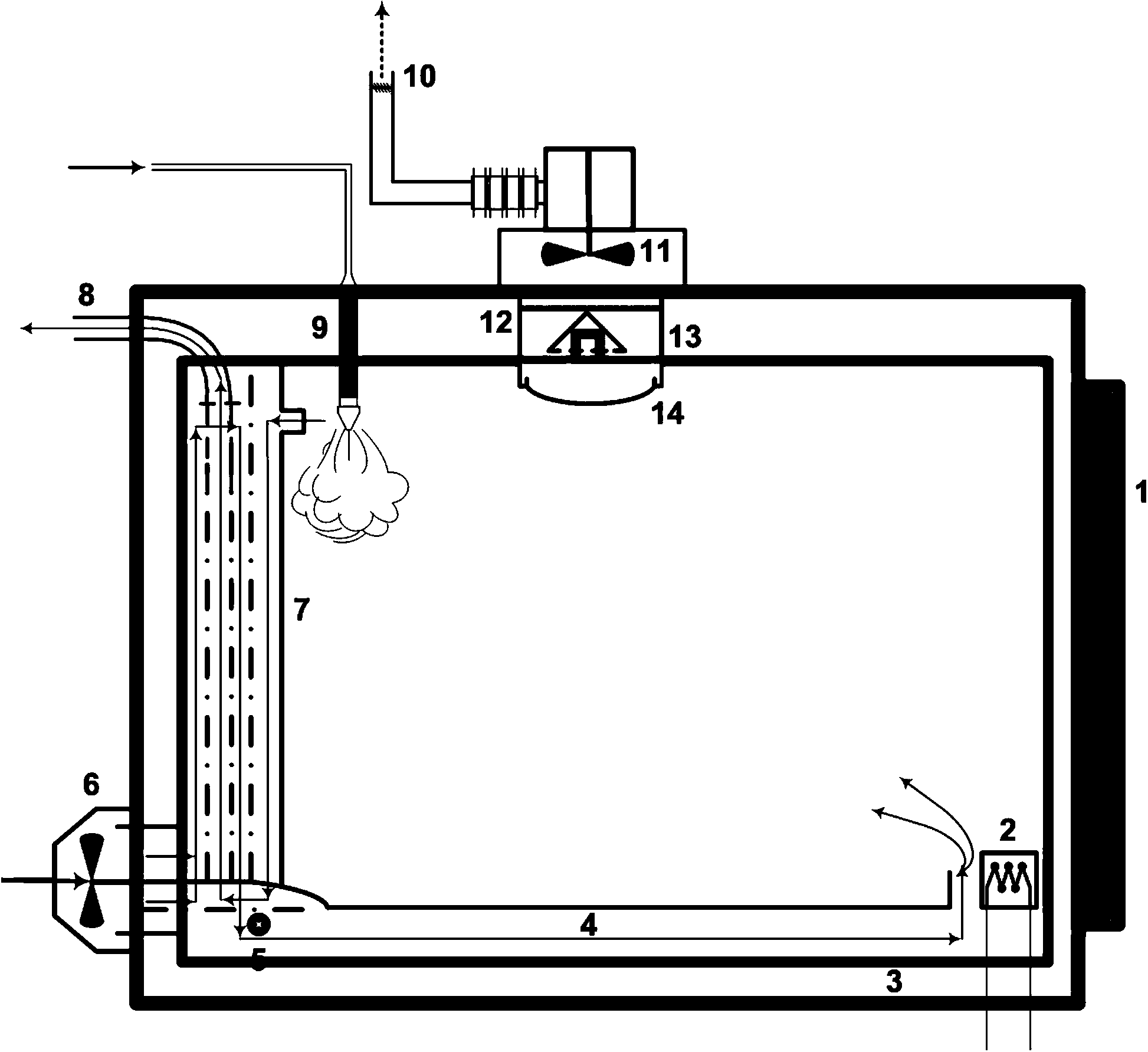

[0029] Such as figure 1 Shown: an internal heat exchange type substance spontaneous combustion test device with a cutter safety control component, including a temperature control component: a conventional intake fan 6, a heat exchanger 7, an electric heating rod 5, an intake duct 4, a conventional Exhaust pipe 8; safety control component: composed of one-way valve 14, aluminum foil sealing film 12, pyramid cutter 13, emergency exhaust fan 11, emergency exhaust pipe 10, inert gas nozzle 9; feedback control component: composed of The temperature sensor 2 integrated in the device is connected with an external controller.

[0030] The box body includes an outer shell, a heat-insulating box wall 3 composed of heat-insulating materials installed around the inner wall, and an insulating door and an observation window 1 installed on the outer shell, wherein the observation window is made of tempered glass. The heat exchanger 7 is arranged on the back panel of the rear part of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com