Manufacturing method of multi-channel light filtering micro lens array

A technology of microlens array and manufacturing method, applied in the field of optical devices, to achieve monochrome imaging and color reconstruction, compact structure, and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

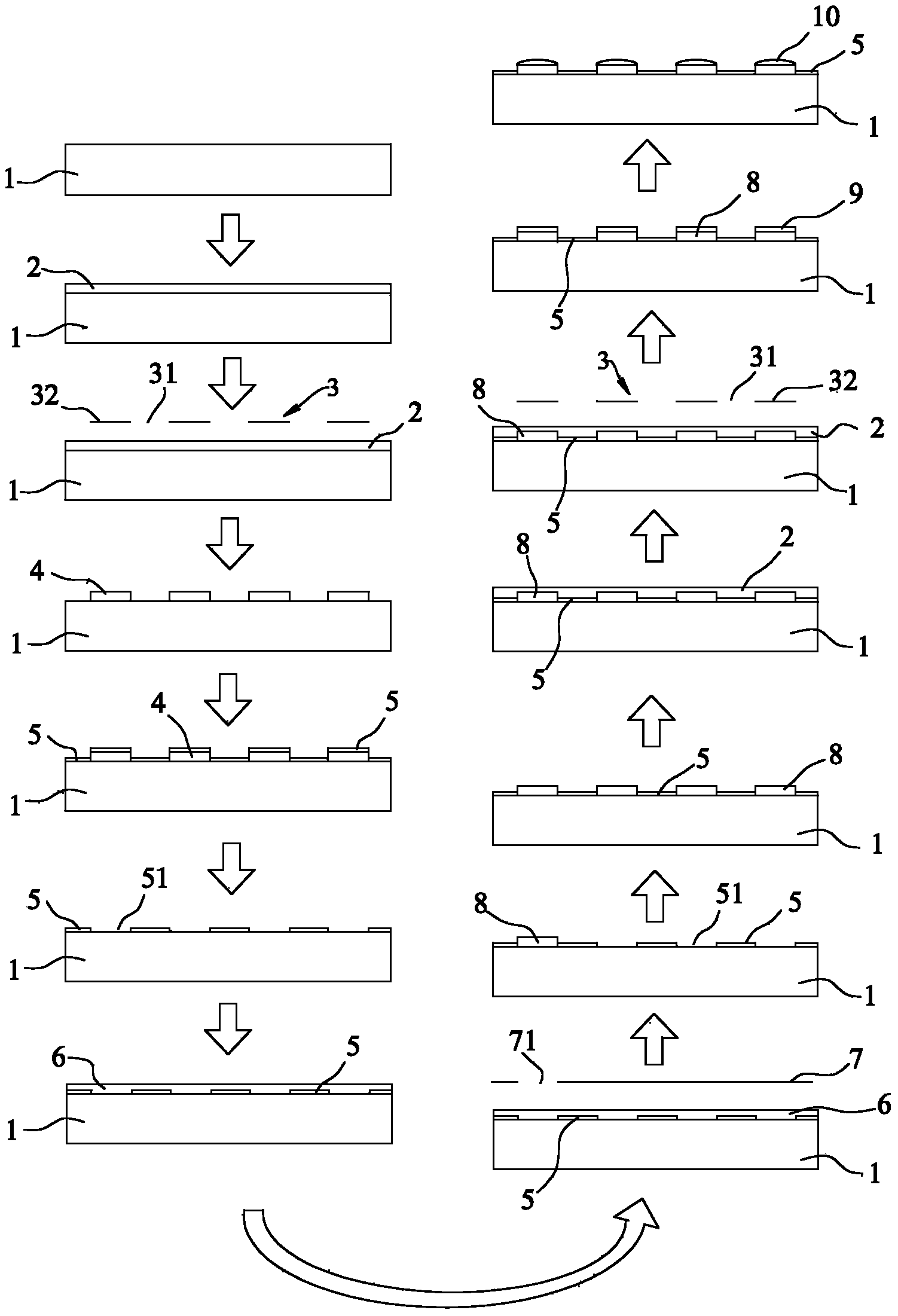

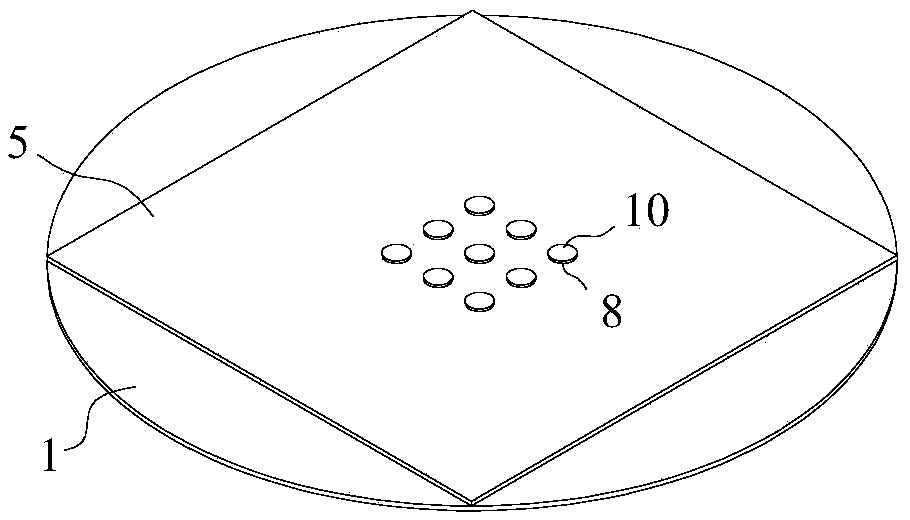

[0023] refer to figure 1 , figure 2 , The invention provides a manufacturing method of a multi-channel filter microlens array, compared with the traditional microlens array, it can filter and condense light of several different spectra at the same time. The set of microlenses is applied in a multispectral imaging system to realize monochrome imaging and color reconstruction. In this way, one filter structure can be reduced compared with the traditional multispectral imaging system, and the problem of alignment between the filter and the microlens array is avoided. This method mainly comprises the following steps:

[0024] 1. Take a glass sheet with a flat surface and high light transmittance as substrate 1. After cleaning the substrate with water and acetone, place it in an oven and bake it at 130°C for 10 minutes to remove water vapor and residual acetone. After natural cooling, the AZ4620 positive photoresist 2 was spin-coated on the substrate 1, and the spin coating par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com