Lithium titanate electrode plate and lithium ion battery

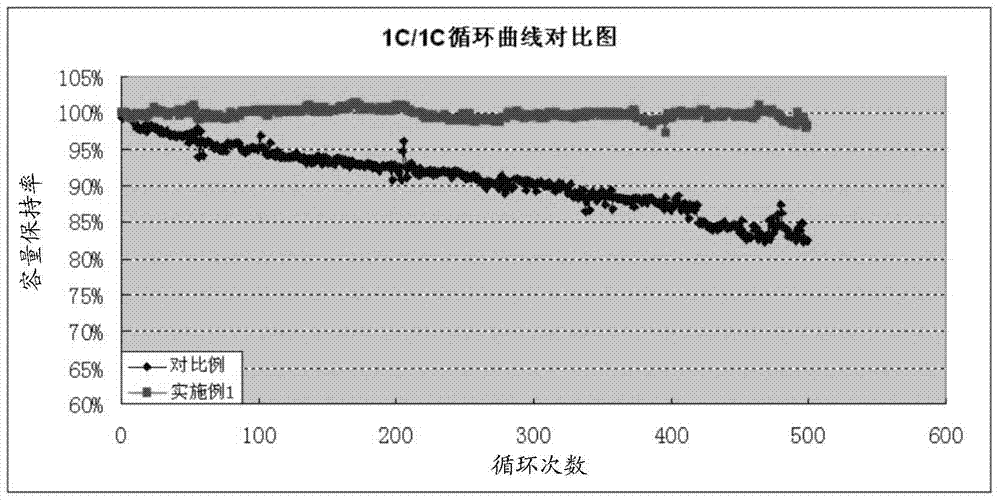

A technology of lithium titanate and electrode sheet is applied in the field of lithium titanate electrode sheet and lithium ion battery to achieve the effect of improving cycle performance and preventing battery bulging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

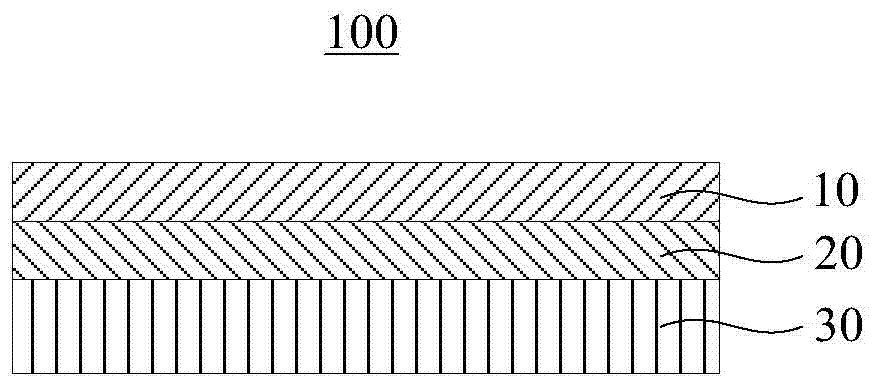

[0074] Preparation of lithium titanate electrode sheet and lithium ion battery

[0075] 1. Take 100g of polyvinylidene fluoride binder, 20g of acetylene black conductive agent and 2kg of lithium titanate, and evenly disperse them in 2kg of N-methylpyrrolidone, stir and disperse at a high speed of 3000r / min, and stir evenly to obtain lithium titanate coating slurry;

[0076] 2. Coat the lithium titanate coating slurry on the copper foil and dry it at 90°C to form a lithium titanate coating on the copper foil. The thickness of the lithium titanate coating is 150 microns;

[0077] 3. Take 10g of polyvinylidene fluoride binder, 15g of acetylene black conductive agent and 200g of artificial graphite with an average particle size of 500nm, and uniformly disperse them in 200g of N-methylpyrrolidone, stir and disperse at a high speed of 3000r / min, stir Uniformly obtain carbon coating slurry;

[0078] 4. Coat the carbon coating slurry on the lithium titanate coating, dry it at 90°C, ...

Embodiment 2

[0081] Preparation of lithium titanate electrode sheet and lithium ion battery

[0082] 1. Take 60g of polyvinylidene fluoride binder, 30g of acetylene black conductive agent and 2kg of lithium titanate, and evenly disperse them in 2.5kg of N-methylpyrrolidone, stir and disperse at a high speed of 4000r / min, and stir evenly to obtain titanic acid Lithium coating paste;

[0083] 2. Coat the lithium titanate coating slurry on the copper foil and dry it at 95°C to form a lithium titanate coating on the copper foil. The thickness of the lithium titanate coating is 80 microns;

[0084] 3. Take 15g of polyvinylidene fluoride binder, 15g of acetylene black conductive agent and 200g of artificial graphite with an average particle size of 800nm, and evenly disperse them in 220g of N-methylpyrrolidone, and stir and disperse at a high speed of 3500r / min. Stir evenly to obtain carbon coating slurry;

[0085] 4. Coat the carbon coating slurry on the lithium titanate coating, dry it at 10...

Embodiment 3

[0088] Preparation of lithium titanate electrode sheet and lithium ion battery

[0089] 1. Take 10g of polyvinylidene fluoride binder, 10g of acetylene black conductive agent and 0.98kg of lithium titanate, and evenly disperse them in 2.3kg of N-methylpyrrolidone, stir and disperse at a high speed of 3000r / min, and stir evenly to obtain titanium Lithium acid coating slurry;

[0090] 2. Coat the lithium titanate coating slurry on the copper foil and dry it at 105°C to form a lithium titanate coating on the copper foil. The thickness of the lithium titanate coating is 60 microns;

[0091] 3. Take 5g of polyvinylidene fluoride binder, 9g of acetylene black conductive agent and 190g of soft carbon with an average particle size of 1 micron, and evenly disperse them in 250g of N-methylpyrrolidone, and stir and disperse at a high speed of 5000r / min. Stir evenly to obtain carbon coating slurry;

[0092] 4. Coat the carbon coating slurry on the lithium titanate coating, dry it at 110...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com