A battery thermal management system based on pulsating heat pipes

A battery thermal management and pulsating heat pipe technology, which is applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of power battery thermal management that cannot be solved well, liquid cooling technology requires high sealing, and battery wall heat exchange Low coefficient and other problems, to achieve the effect of enhancing heat exchange efficiency, simple structure, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

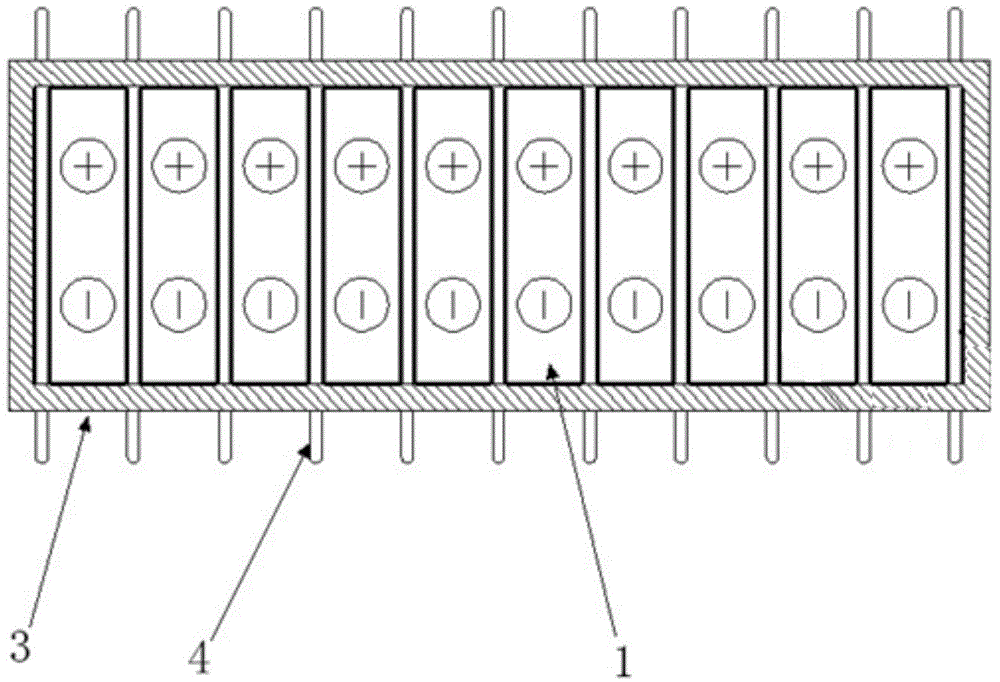

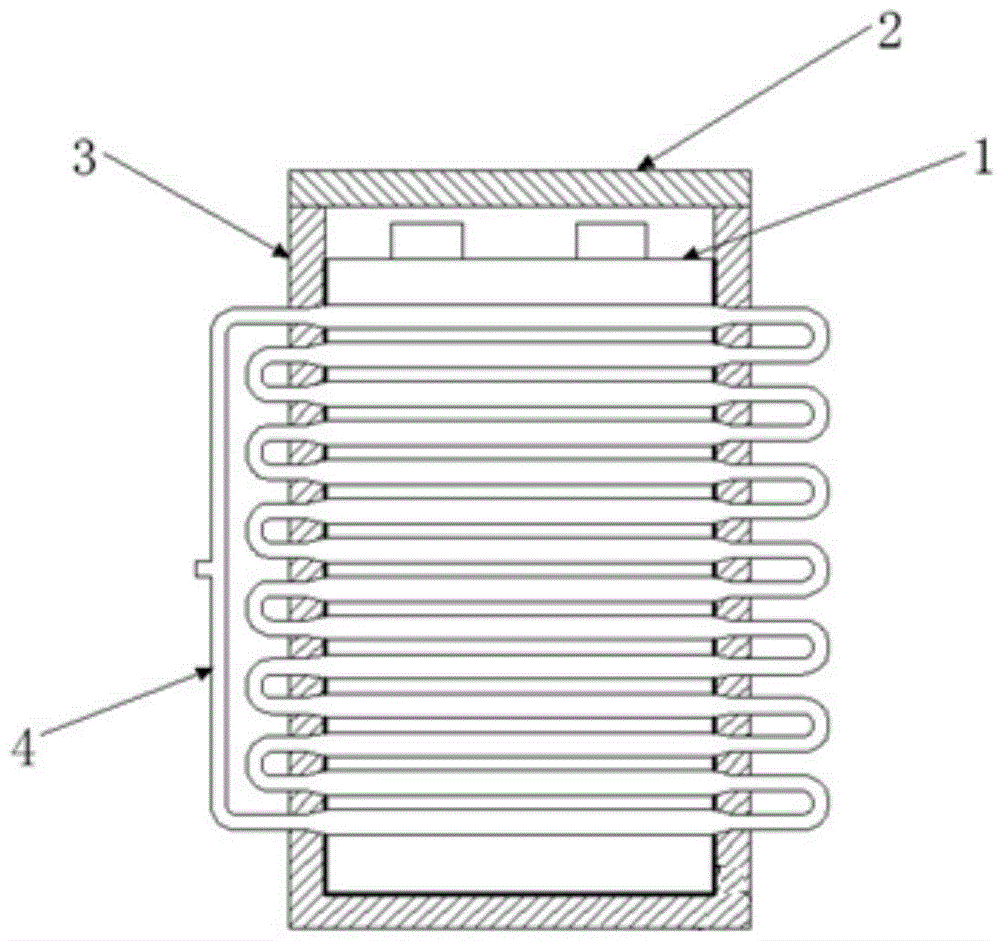

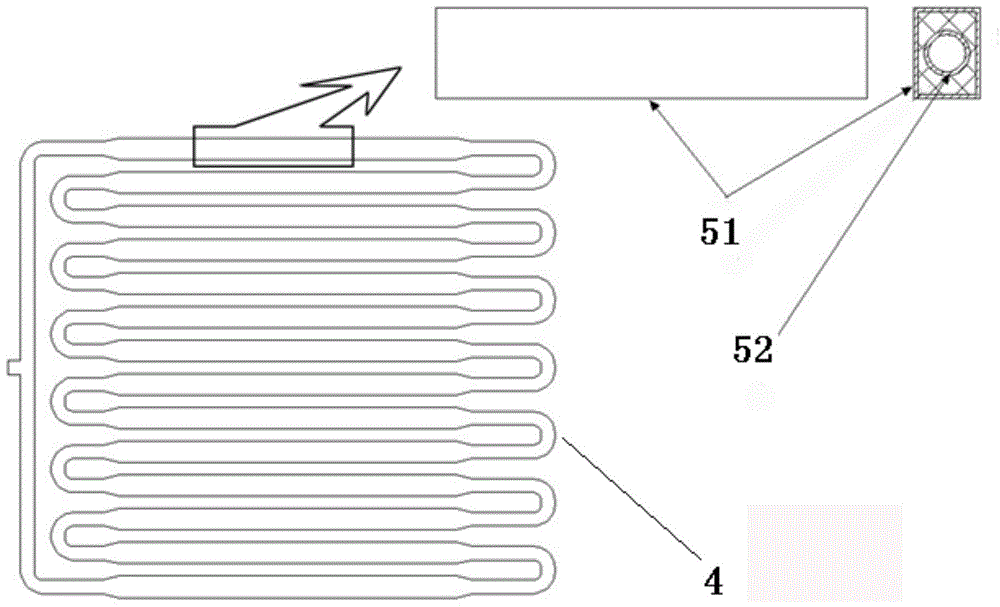

[0021] Such as figure 1 As shown, a battery thermal management system based on pulsating heat pipes includes a battery module box 3 with a through hole 8 on the box wall and a module box top cover 2. Several battery cells 1 and Several pulsating heat pipes 4, the pulsating heat pipes 4 include an evaporating end 5 and a condensing end 6, the evaporating ends 5 of the pulsating heat pipes 4 are bent back and forth and attached to the shell of the battery cell 1 such as figure 2 As shown, the condensing end 6 protrudes from the battery module box 3 through the through hole 8, and the air passing through the condensing end 6 is used to accelerate heat transfer when the electric vehicle is moving; the size of the battery cell 1 is designed according to the size of the battery module box 3 , the bottom of the battery cell 1 is bonded to the battery module box 3, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com